Light-guide Apparatus With Micro-structure, Back Light Unit Comprising The Same And Liquid Crystal Display Comprising The Same

A light guide device and light guide layer technology, which is applied to lighting devices, fixed lighting devices, instruments, etc., can solve the problems of difficult processing of rhombus modules, high cost of backlight modules, and easy damage of microstructures, etc. Utilization rate, reduction of film application procedures, uniform light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0125] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

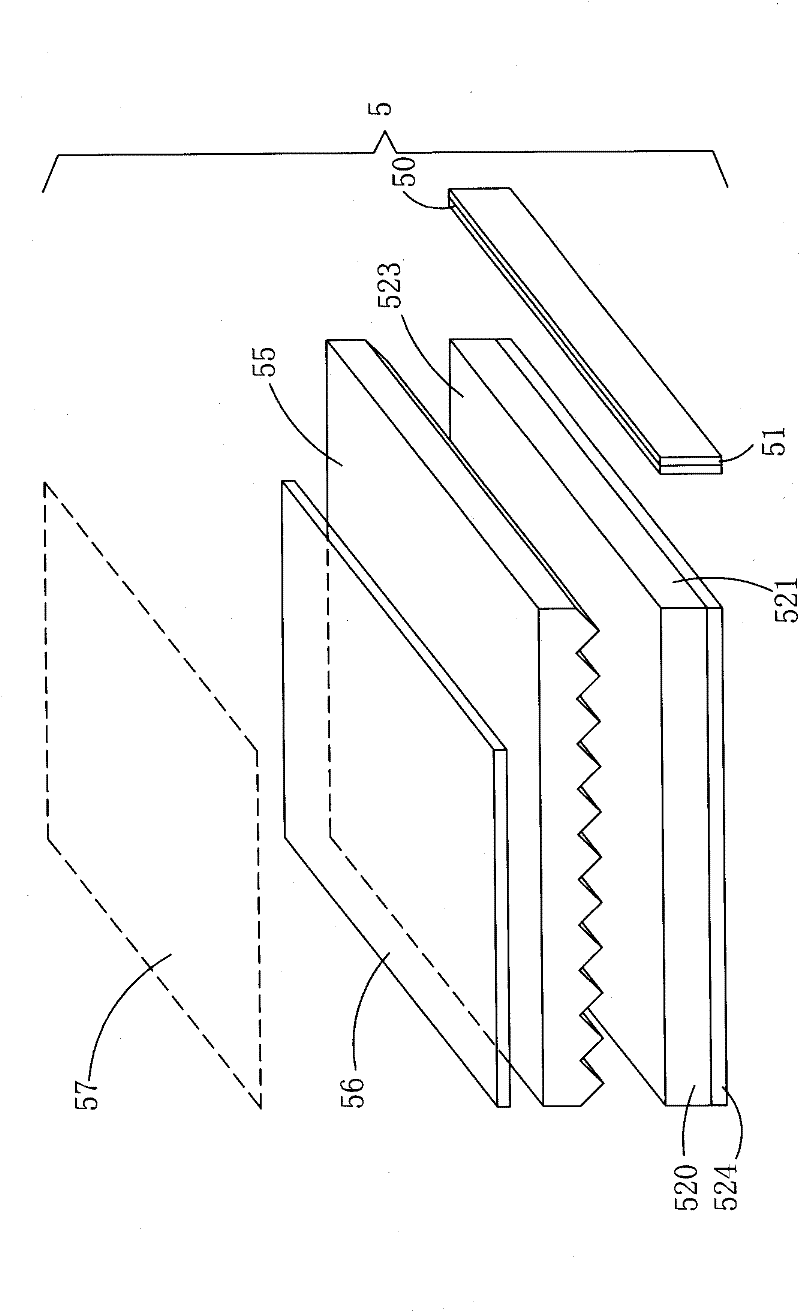

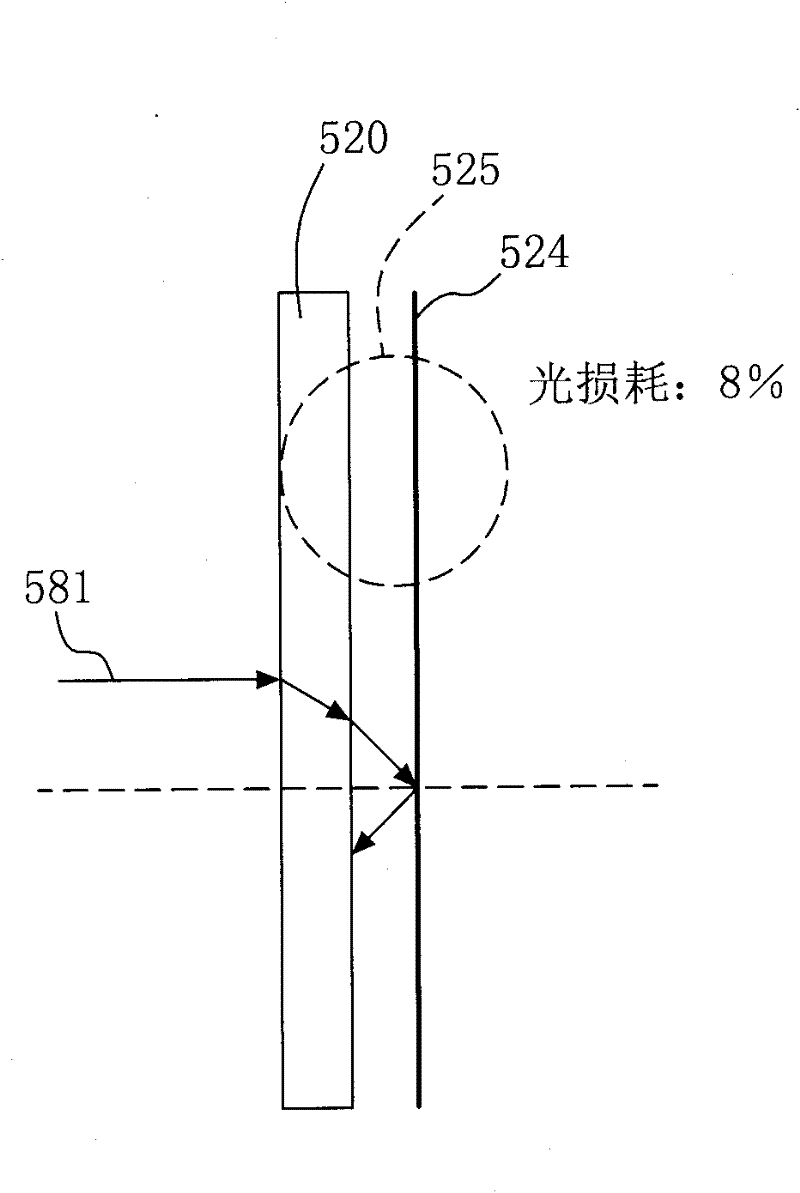

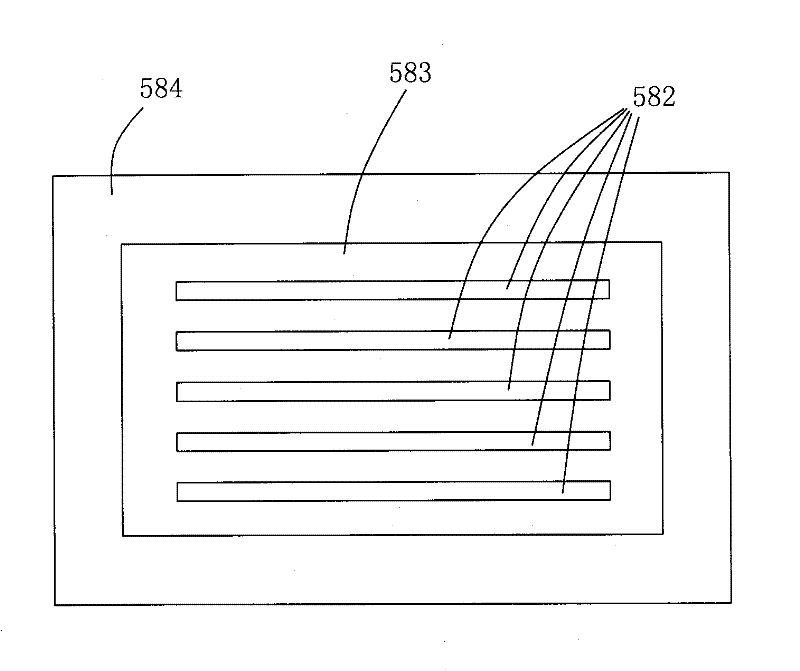

[0126]The invention relates to a light guiding device. The light guide device is integrally formed by a co-extrusion process and has the functions of reflection, light uniformity and light guide. It is used with a side light source to form a backlight module of a display. Likewise, the light guide device can also be applied to liquid crystal displays.

[0127] In order to more clearly describe the light guide device proposed by the present invention and the backlight module and liquid crystal display provided with the light guide device, detailed description will be given below with reference to the accompanying drawings.

[0128] (one) summary to device (three-layer structure) of the present invention:

[0129] l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com