Mask plate defect detection method

A defect detection and mask technology, applied in the field of defect detection, can solve the problems of unsatisfactory detection effect of foggy defects and fine organic pollution, and achieve the effect of reducing manual intervention and good detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

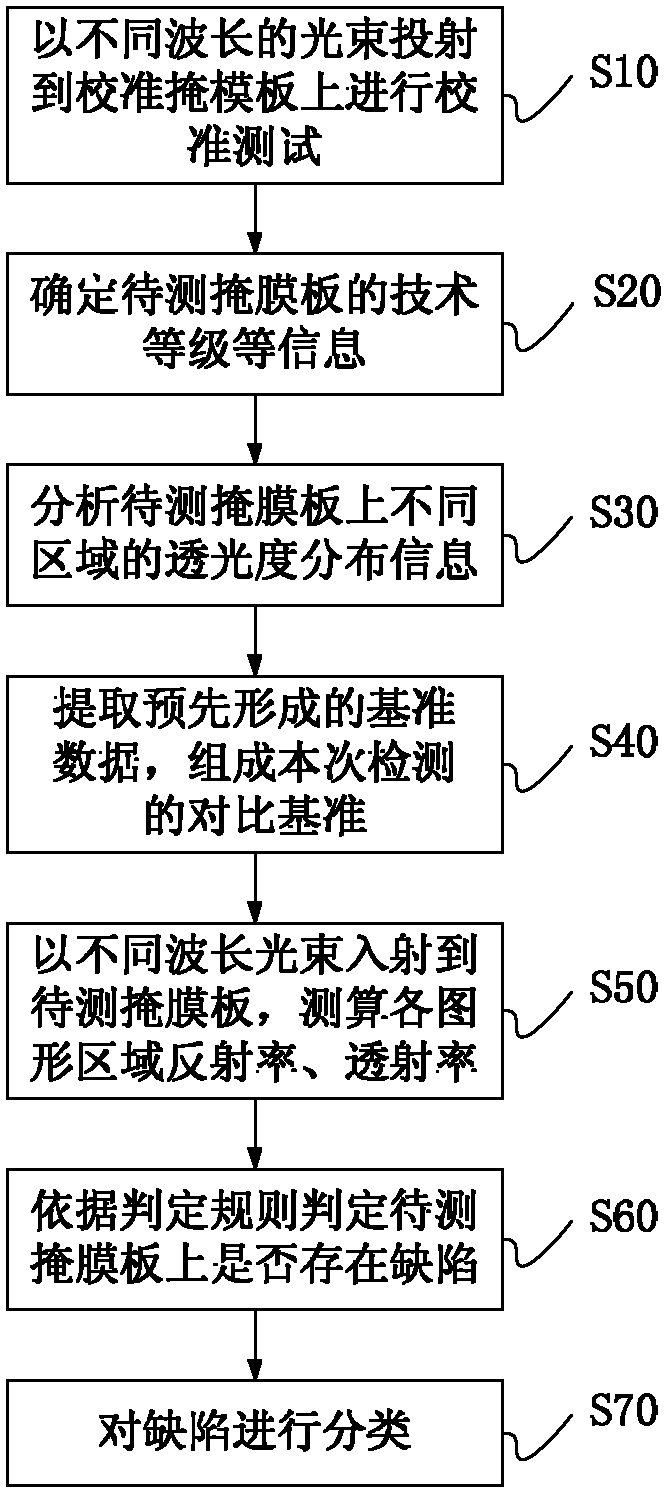

[0015] A mask defect detection method disclosed in the present invention is as follows: figure 1 As shown, it specifically includes the following steps:

[0016] S10: Projecting beams of different wavelengths onto the calibration mask to perform a calibration test;

[0017] S20: Determine the technical level, technical node, and design rules of the mask to be tested;

[0018] S30: analyzing the light transmittance distribution information of different graphic regions of the mask to be tested;

[0019] S40: Extract relevant benchmark data from the benchmark database to form a comparison benchmark for this detection;

[0020] S50: Use beams of different wavelengths to project onto the mask to be tested, and measure and calculate the reflectance and transmittance information of each graphic area;

[0021] S60: Compare the reflectan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com