Voltage-regulating winding structure of splitting winding type on-load tap-changing transformer

A voltage regulating transformer and voltage regulating winding technology, applied in the direction of transformer/inductor coil/winding/connection, transformer, variable transformer, etc., can solve the problems of large number of lead wires, unfavorable design and manufacture, etc. Easy-to-wind effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

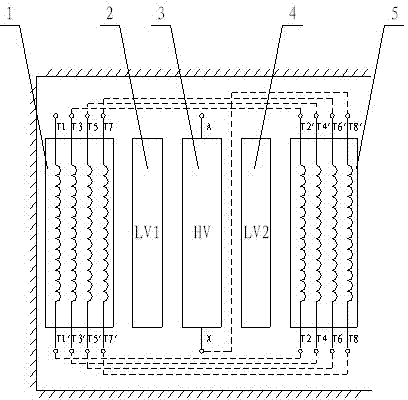

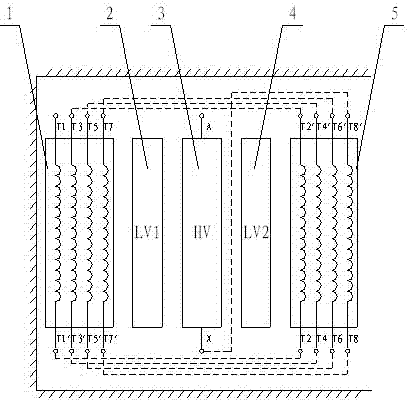

[0011] A voltage regulating winding structure of a split on-load voltage regulating transformer. There are five windings on the iron core of the transformer. 3—outer low-voltage winding 4—outer voltage regulating winding 5; The voltage winding is serially connected to the end of the high voltage winding step by step. When the inner voltage regulating winding and the outer voltage regulating winding are all connected in series to the end of the high voltage winding step by step, the high voltage voltage of the transformer is at the limit tap. The wiring characteristics of the said voltage regulating winding are: the internal voltage regulating winding and the external voltage regulating winding are interleaved and connected in series at the end of the high voltage winding step by step. This embodiment is an eight-stage voltage regulation structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com