Shell structure of automobile body control module (BCM)

A control module and automobile body technology, which is applied in the direction of electrical equipment shell/cabinet/drawer, vehicle parts, casing/cabinet/drawer parts, etc., which can solve the problem that the body control module shell cannot adapt to the change of installation position and has no drainage Structure and other issues, to save the assembly process, increase the service life, increase the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

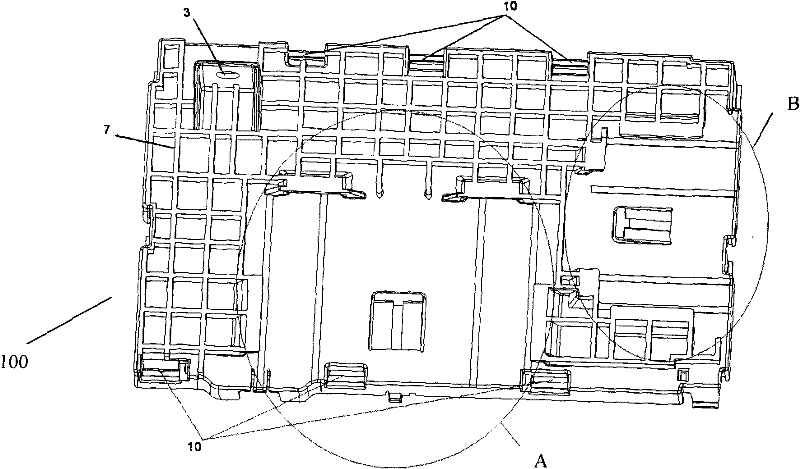

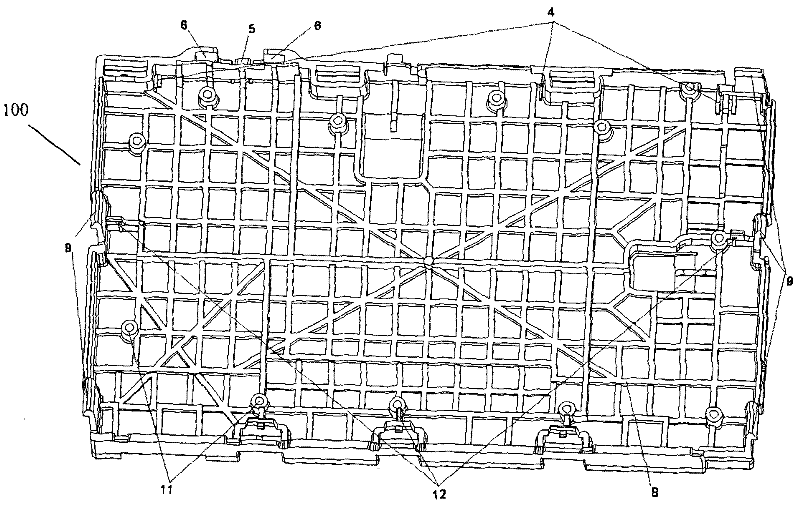

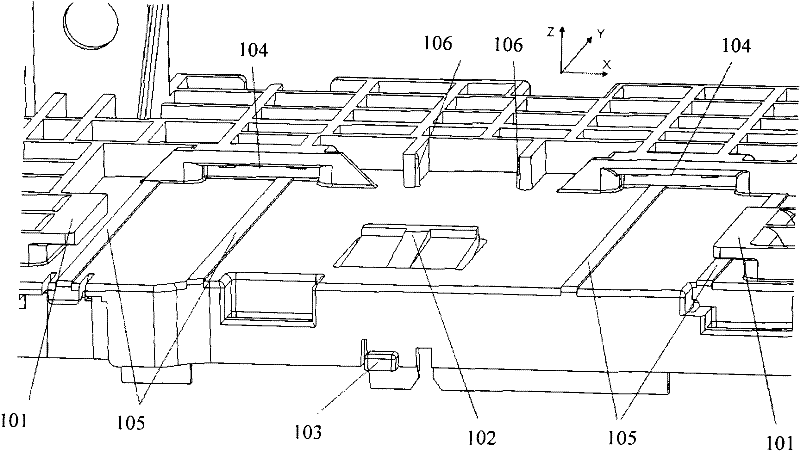

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the automobile body control module shell structure of the present invention is composed of injection molded parts, wherein the injection molded parts are composed of an upper cover 100 and a lower cover 200, and the middle and lower parts of the outer side of the upper cover 100 are provided with Two first installation guide grooves 101 and a first positioning buckle 102, the first positioning buckle 102 is composed of a first elastic arm, and the angle between the first elastic arm and the plane of the upper cover 100 is greater than 0 degrees , one end of the first elastic arm is higher than the upper cover 100, and the lower edge of the upper cover 100 is provided with a boss 103 with an elastic structure, and the two first installation guide grooves 101 are spaced parallel and vertical On the lower side of the upper cover 100, two bracket limiting grooves 104 are arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com