Buffering and damping device for automobile engine

A technology for automobile engines and shock absorbers, which is applied in power units, jet propulsion devices, internal combustion propulsion devices, etc., can solve problems such as opening of glue, no excessive restriction on deformation amount, cracking of glue, etc. Convenience and the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

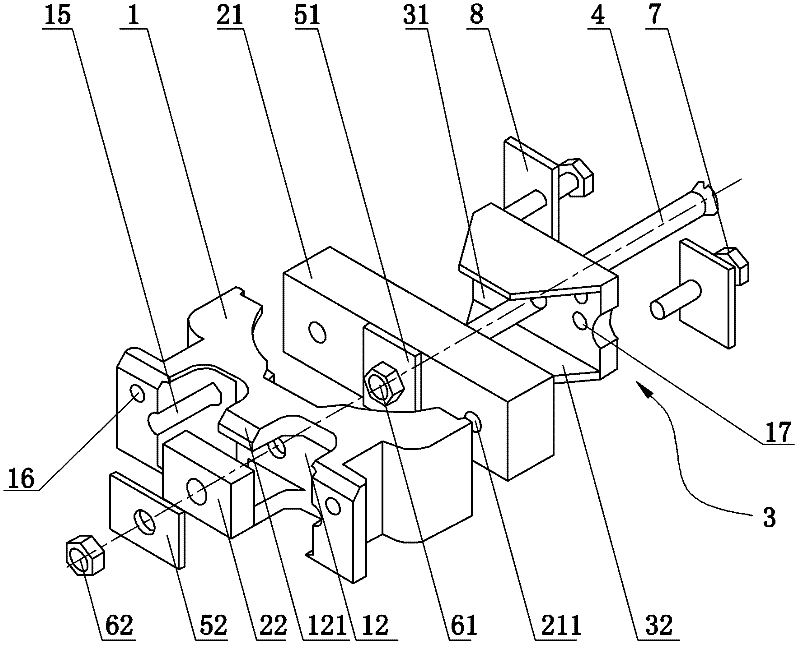

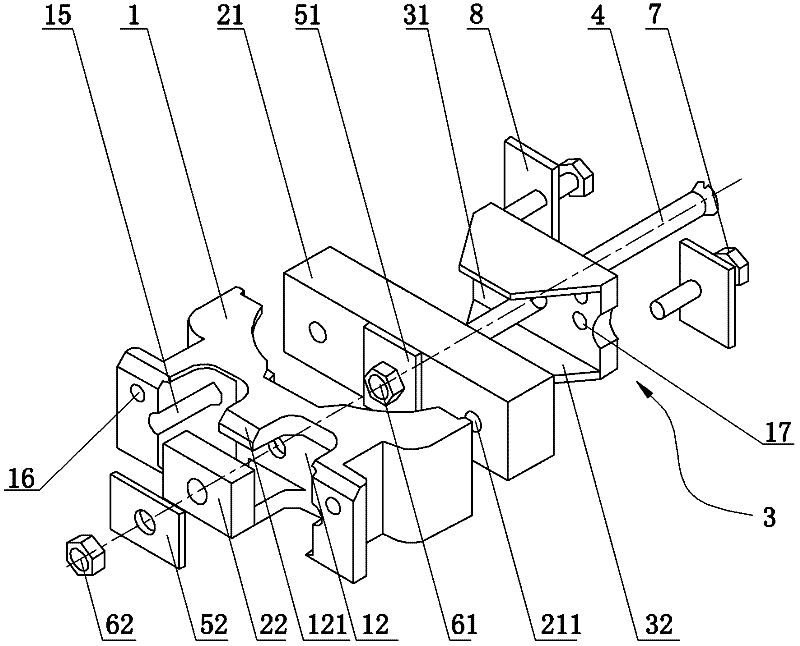

[0020] Such as figure 1 As shown, it is an assembly diagram of an embodiment of the automobile engine buffer and shock absorber of the present invention. The automobile engine buffer and shock absorber includes a base 1, and the base 1 is detachably fixed on the vehicle frame. The fixing method can be A vehicle frame connecting hole 16 is opened on the base 1, and is fixed on the vehicle frame by bolts.

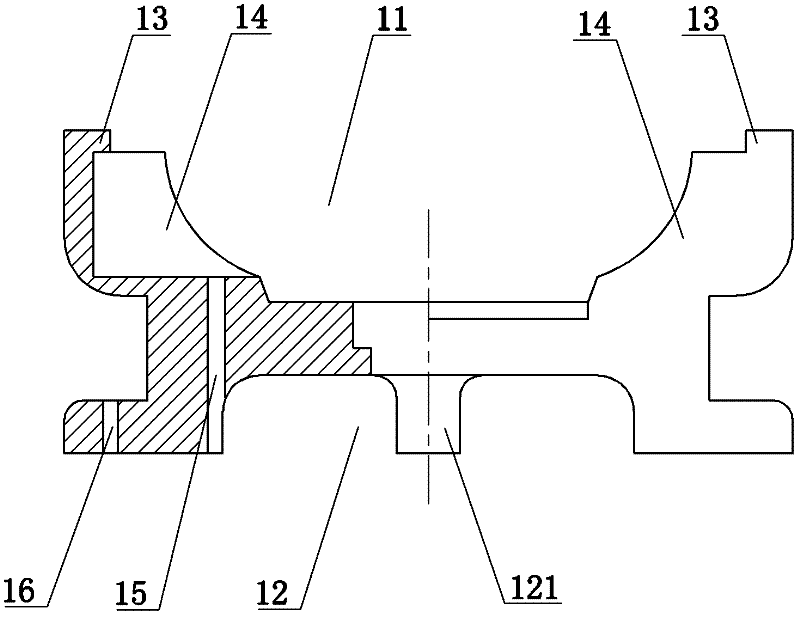

[0021] The upper surface of the base 1 is provided with an upper groove 11, and an upper rubber block 21 for buffering and shock absorption is arranged in the upper groove 11, and opposite probes are arranged at both ends of the upper groove 11. Protruding portion 13, the protruding portion 13 is pressed and buckled on the two ends of the upper rubber block 21 respectively, and an upper recess in contact with the upper rubber block 21 is also provided on both sides of the upper groove 11 Groove guard plate 14, like this, described protruding portion 13 and upper groove guard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com