Production processes of rock asphalt modified asphalt and mixture

A technology of modified asphalt and production process, which is used in building thermal insulation materials, building components, buildings, etc., can solve the problem that the dynamic stability of asphalt mixture is not very high, the high temperature rutting resistance of rock asphalt is not significant, and the processing technology of modified asphalt is not enough. Insufficient maturity and other problems to achieve the effect of improving water damage resistance, simple and easy processing, and reducing temperature sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

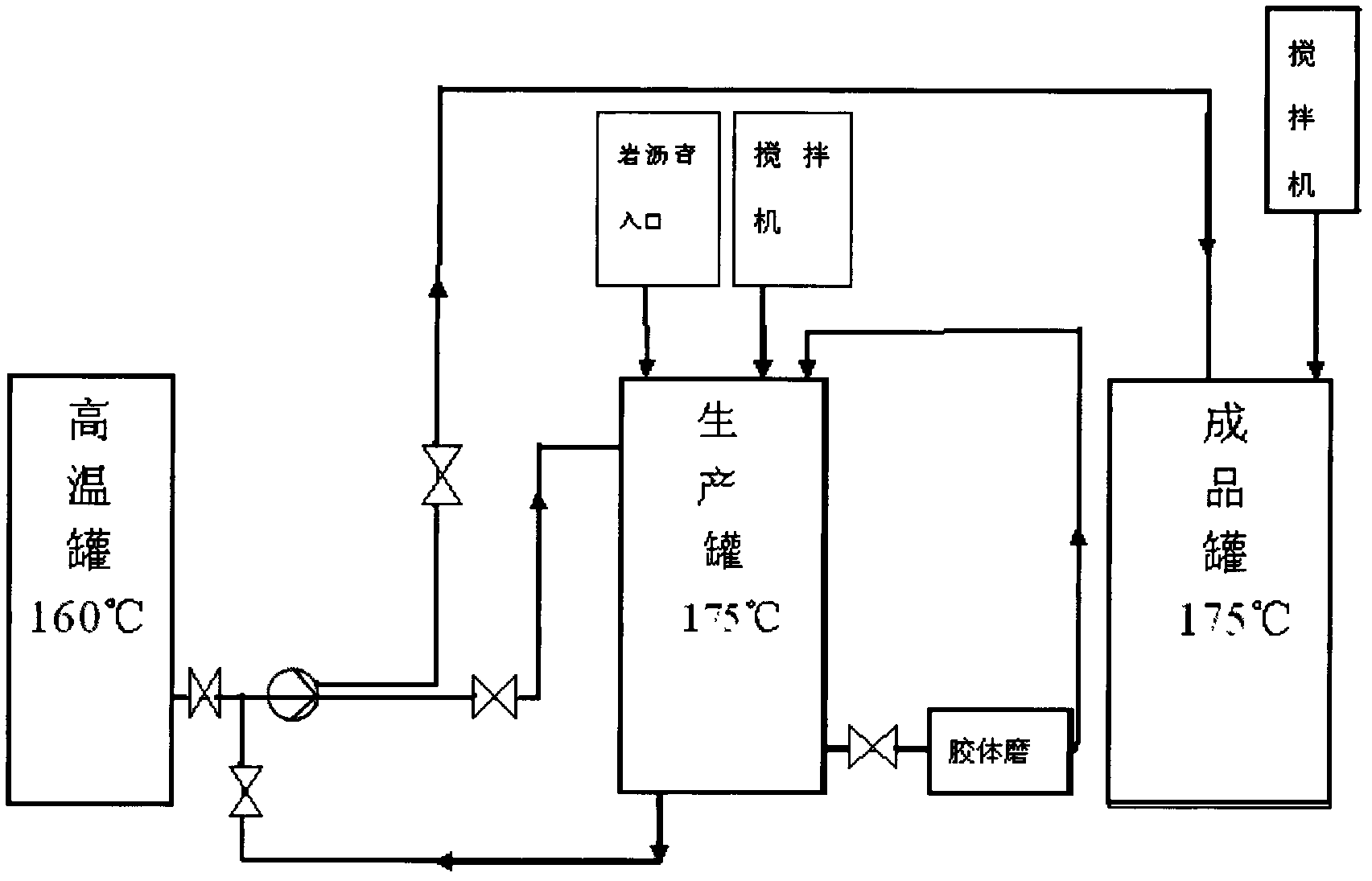

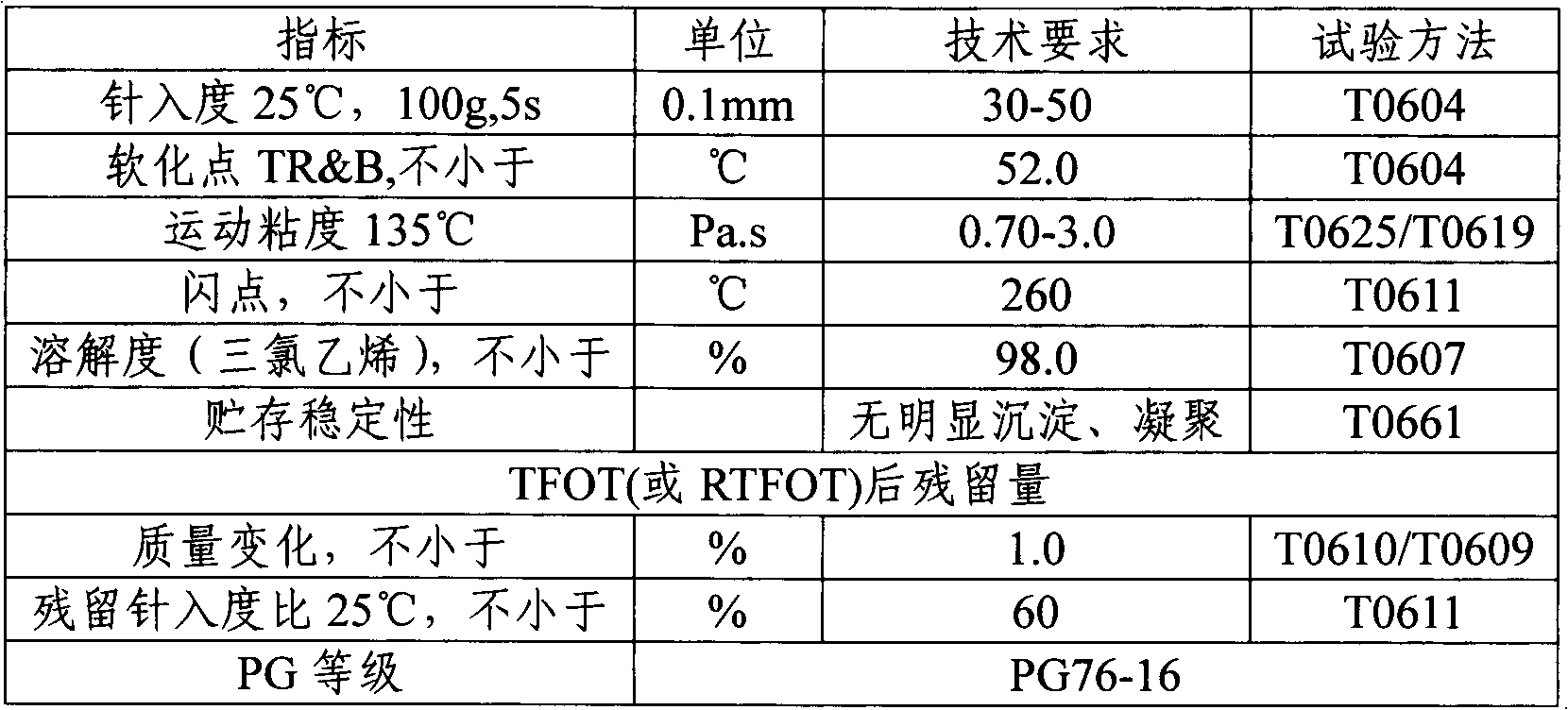

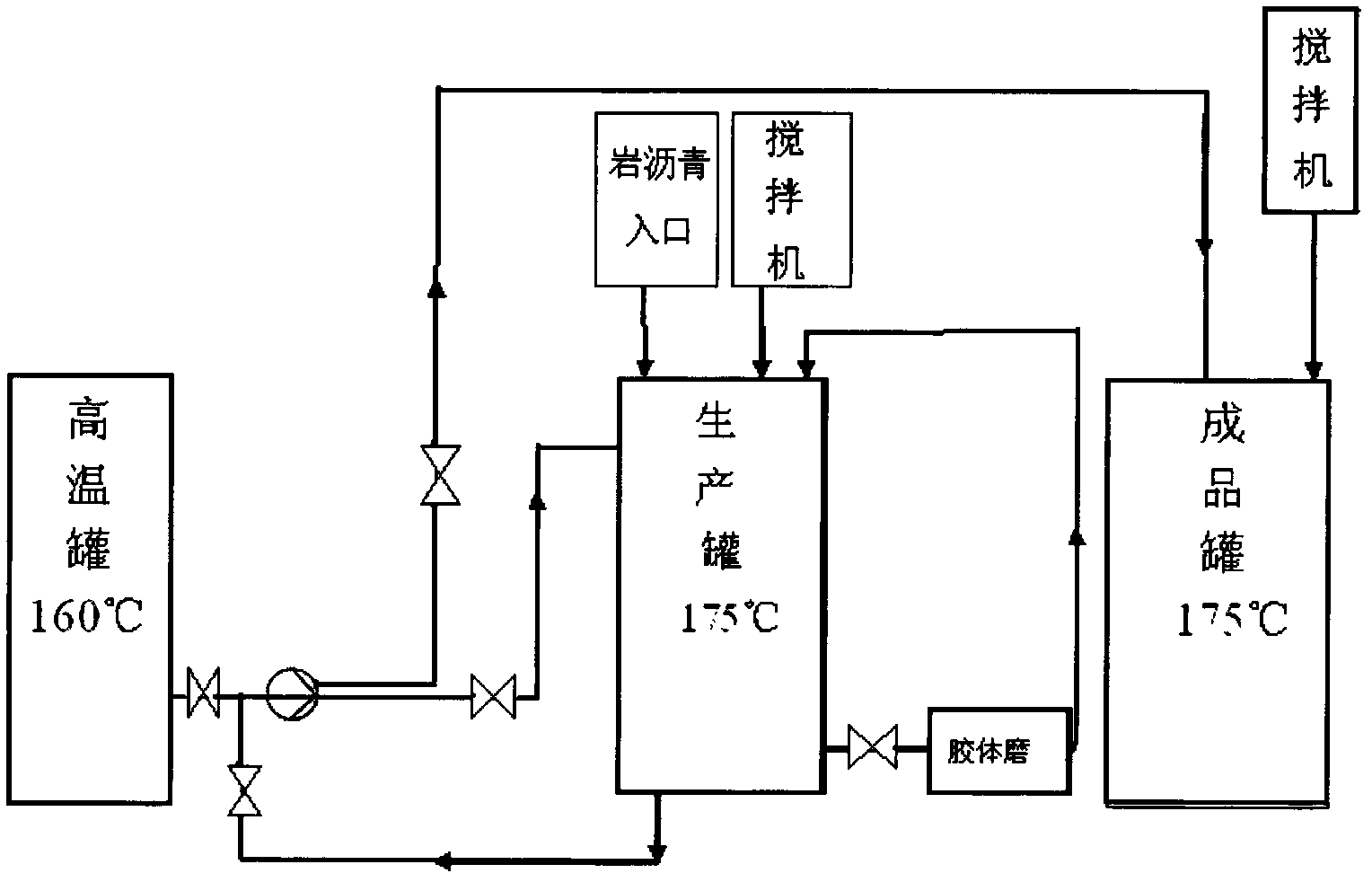

[0034] The technical solution of the present invention is a production process of rock bitumen modified asphalt, and the process includes the following processing steps:

[0035] Step 1: Put the base asphalt into an asphalt tank with a stirring device and heat it to 160°C, and turn on the stirring device;

[0036] The second step: on the basis of the first step, slowly and uniformly add part of rock asphalt and stabilizer, stir while adding, wait until the temperature is heated to 175 ° C, and stir at this temperature for 30 minutes;

[0037] The third step: on the basis of the second step, add the remaining asphalt and continue stirring for 1.5 hours to completely dissolve the asphalt particles, and the part of rock asphalt is 1 / 2 of the total amount of rock asphalt added;

[0038] The fourth step: on the basis of the third step, move the prepared rock asphalt modified asphalt into the finished product storage tank, and stir properly during the storage process.

[0039]Where...

Embodiment 2

[0051] On the basis of Example 1, preferred embodiment of the present invention also has, in the production technique of rock bitumen modified bitumen:

[0052] Step 1: Put the base asphalt into an asphalt tank with a stirring device and heat it to 155°C, and turn on the stirring device;

[0053] The second step: on the basis of the first step, slowly and uniformly add part of rock asphalt and stabilizer, stir while adding, wait until the temperature is heated to 170 ° C, and stir at this temperature for 40 minutes;

[0054] The third step: on the basis of the second step, add the remaining asphalt and continue stirring for 1 hour to completely dissolve the asphalt particles, and the part of rock asphalt is 1 / 3 of the total amount of rock asphalt added;

[0055] The fourth step: on the basis of the third step, move the prepared rock asphalt modified asphalt into the finished product storage tank, and stir properly during the storage process.

[0056] Wherein, the base asphalt...

Embodiment 3

[0067] On the basis of Example 1, preferred embodiment of the present invention also has, in the production technique of rock bitumen modified bitumen:

[0068] Step 1: Put the base asphalt into an asphalt tank with a stirring device and heat it to 165°C, and turn on the stirring device;

[0069] The second step: on the basis of the first step, slowly and uniformly add part of rock asphalt and stabilizer, stir while adding, wait until the temperature is heated to 180 ° C, and stir at this temperature for 20 minutes;

[0070] The third step: on the basis of the second step, add the remaining asphalt and continue stirring for 1.2 hours, so that the asphalt particles are completely dissolved, and the part of rock asphalt is 1 / 2 of the total amount of rock asphalt added;

[0071] The fourth step: on the basis of the third step, move the prepared rock asphalt modified asphalt into the finished product storage tank, and stir properly during the storage process.

[0072] Wherein, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com