Pre-tensioned prestressed reinforced concrete precast beam

A technology of prestressed steel bars and prestressed steel strands, applied in the direction of joists, girders, truss beams, etc., can solve the problems of fast construction speed, complex connection node structure, and high manufacturing cost that are difficult to reflect in factory buildings, and achieve beam stiffness Large size, easy installation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

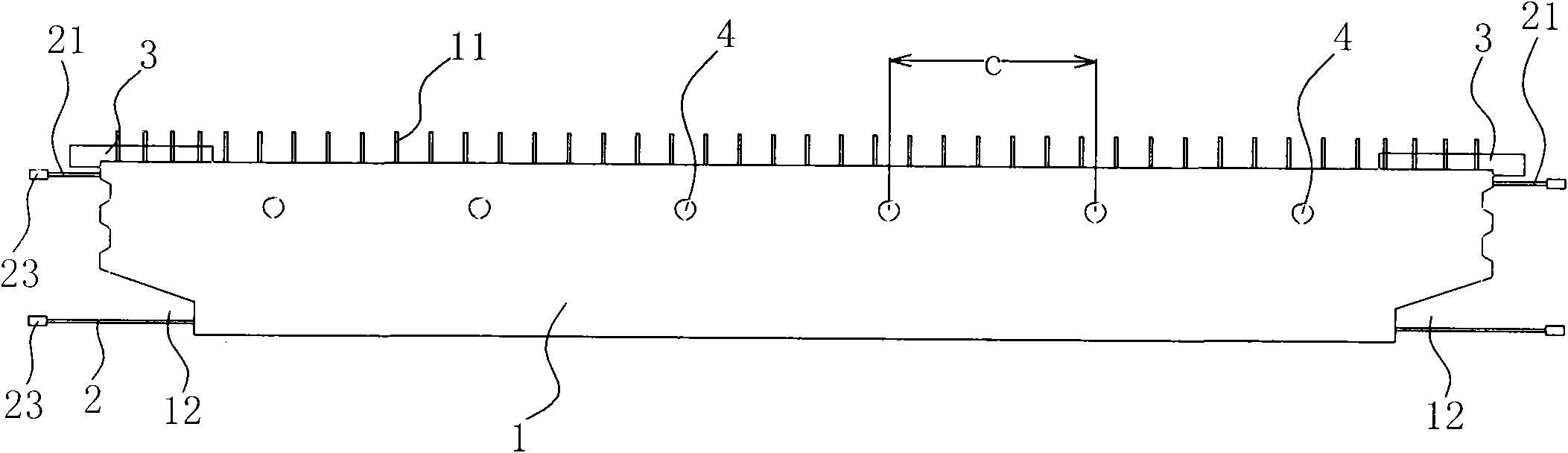

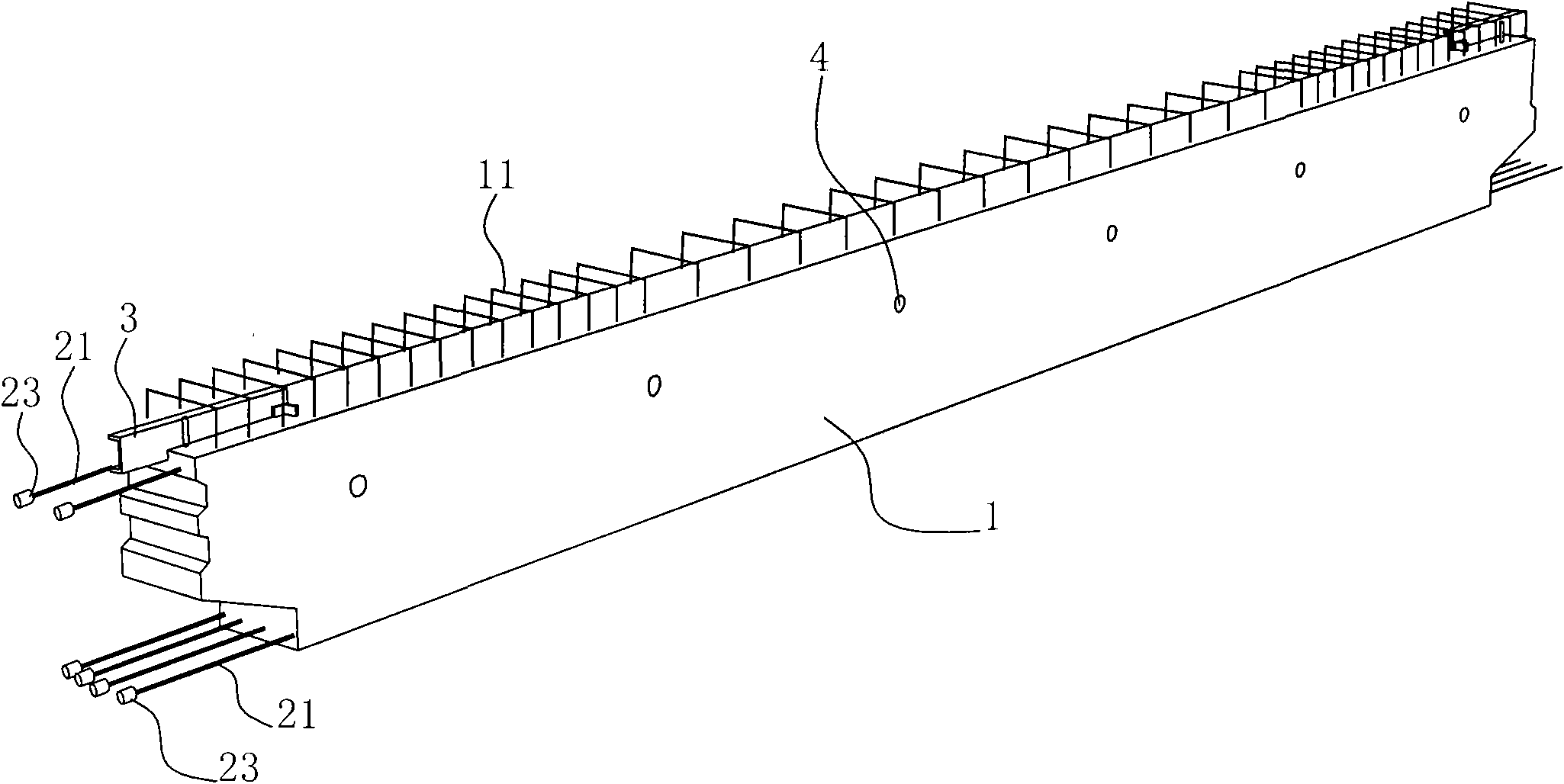

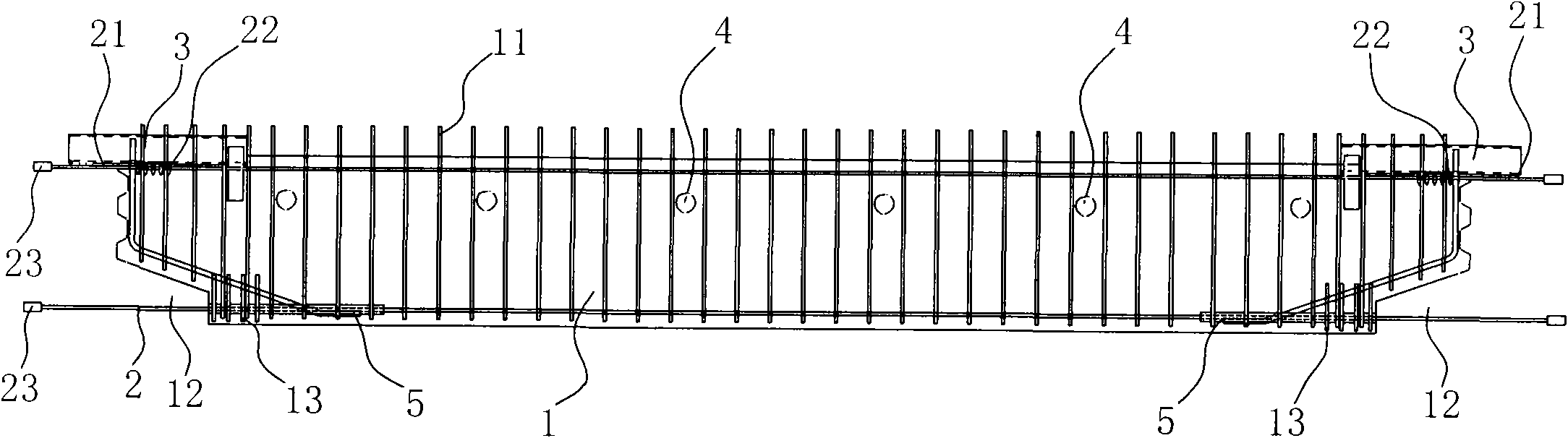

[0027] see figure 1 , figure 2 and image 3 , an embodiment of a pre-tensioned prestressed reinforced concrete prefabricated beam provided in the present invention includes a beam body 1 and a prestressed steel strand 2 embedded in the beam body 1 as a main reinforcement, and the beam body 1 Stirrups 11 are arranged on the top, and part of the stirrups 11 protrudes from the upper surface of the beam body 1, and at least one end of the beam body 1 is provided with a section steel 3 suitable for connecting with an external structure, so Part of the profiled steel 3 is embedded in the beam body 1, and the remaining part is exposed at the end of the beam body 1. At least one side wall of the beam body 1 is longitudinally provided with a plurality of formwork holes 4 .

[0028] The so-called steel strand 2 of the present invention is braided by a plurality of steel wires. This kind of steel strand 2 has high strength and good toughness. After being stretched by the pretensionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com