Spring sheet type pressure release valve

A technology of pressure relief valve and shrapnel, which is applied in the direction of wellbore/well valve device, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of personal injury and damage to high-pressure equipment, and achieve reasonable structure, convenient use, The effect of increasing the pressure regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0015] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the description attached to the description. figure 1 The layout method is described, such as: the position of front, back, top, bottom, left, right, etc.

[0016] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

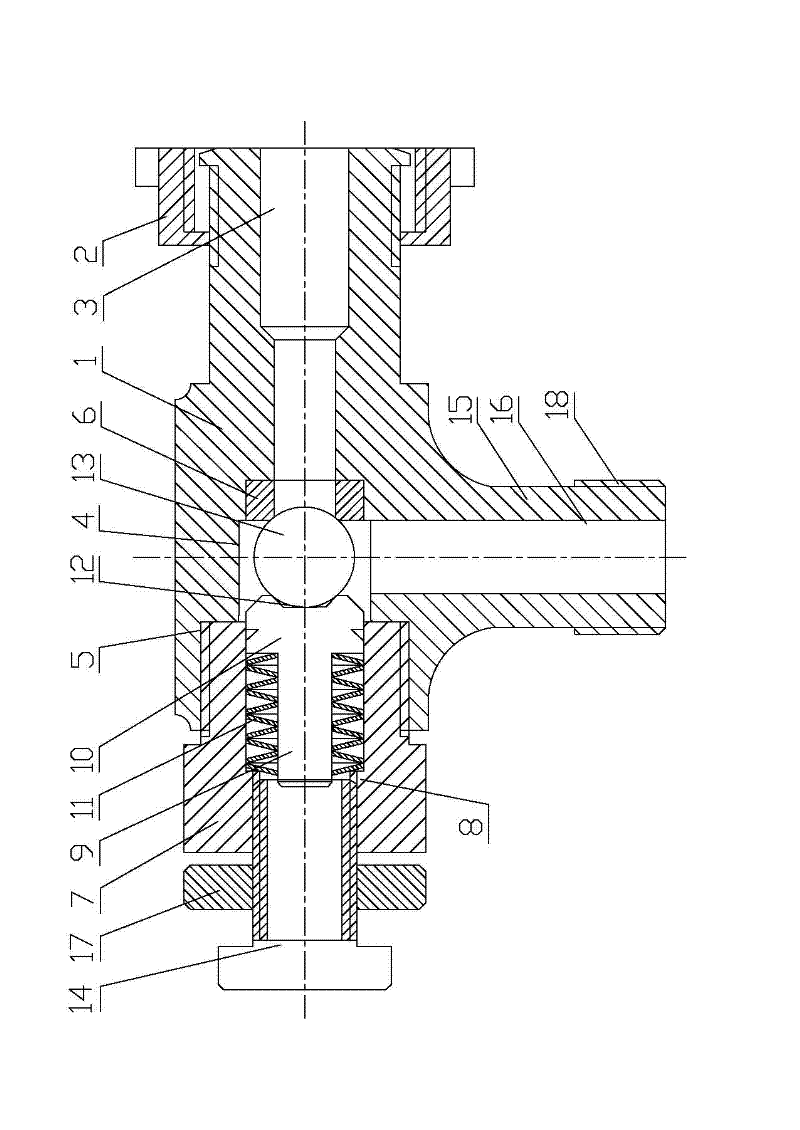

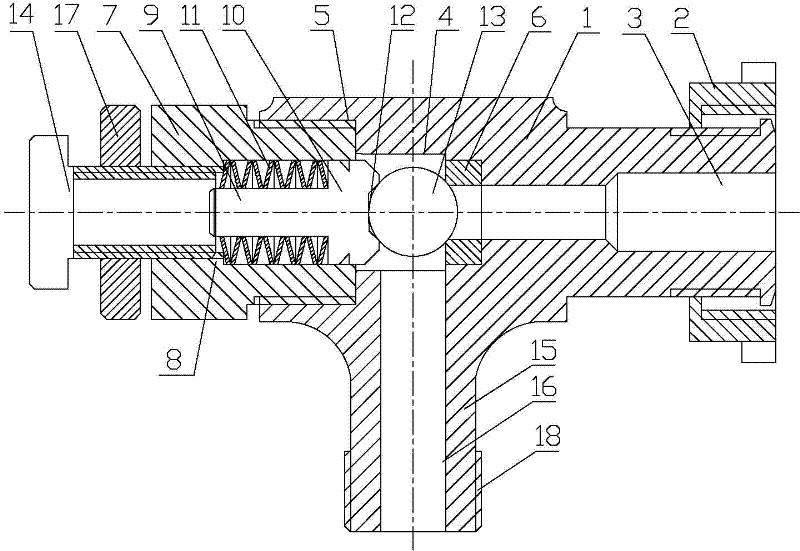

[0017] as attached figure 1 As shown, the shrapnel pressure relief valve includes a valve body 1, a ball seat 6, a cavity spring seat 7, an installation body 9, a spring leaf 11, a ball 13 and an adjusting screw 14; there is an axial passage in the valve body 1 3. In the middle of the valve body, there is a first annular groove 4 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com