Kinematic approximation algorithm having a ruled surface

A technology of rules and algorithms, which is applied in the field of kinematics approximation algorithms using ruled surfaces, can solve the problems of local errors in tool positioning data, high time consumption, and troublesome problems, and achieve the effect of small global error checking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

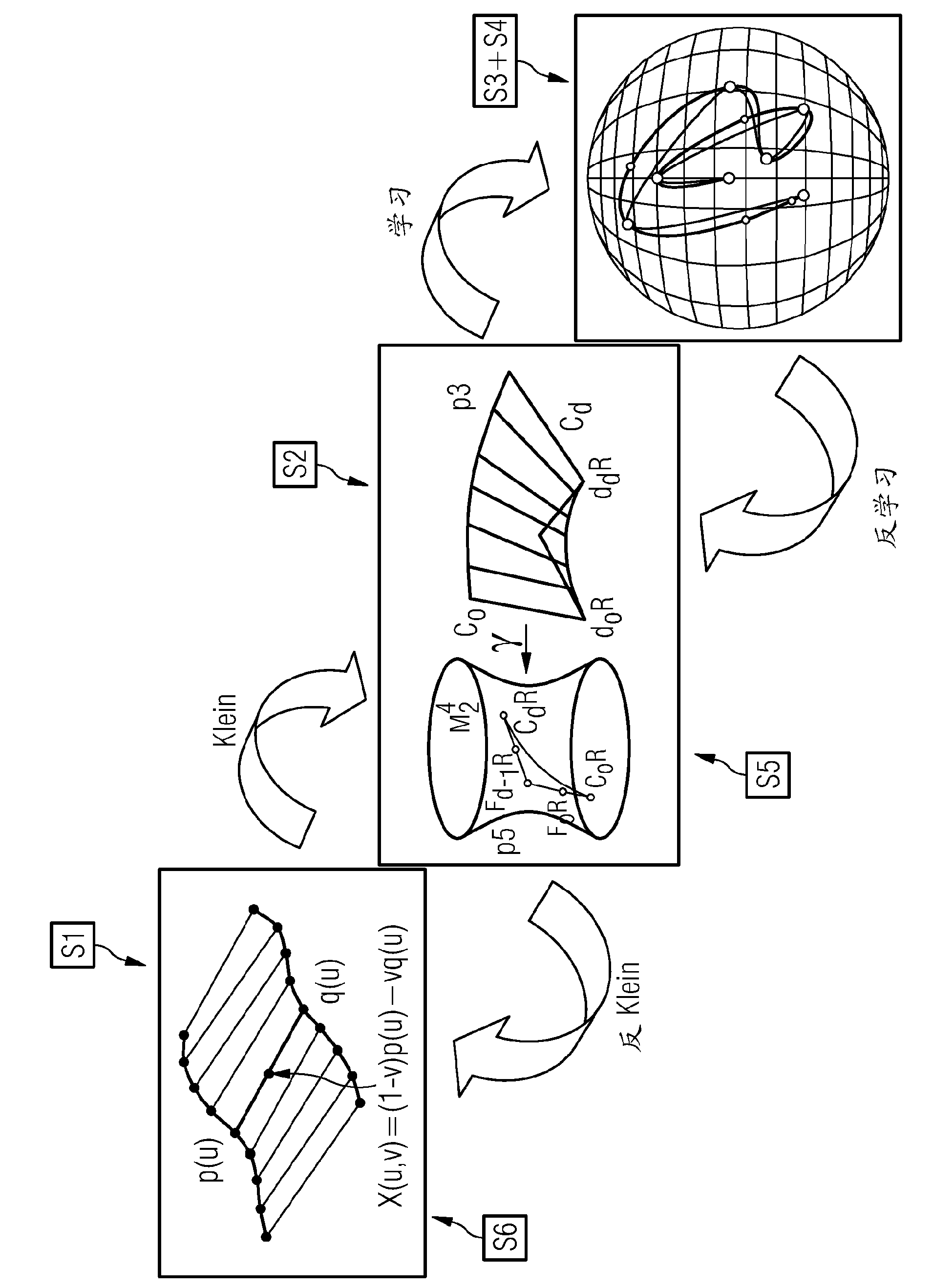

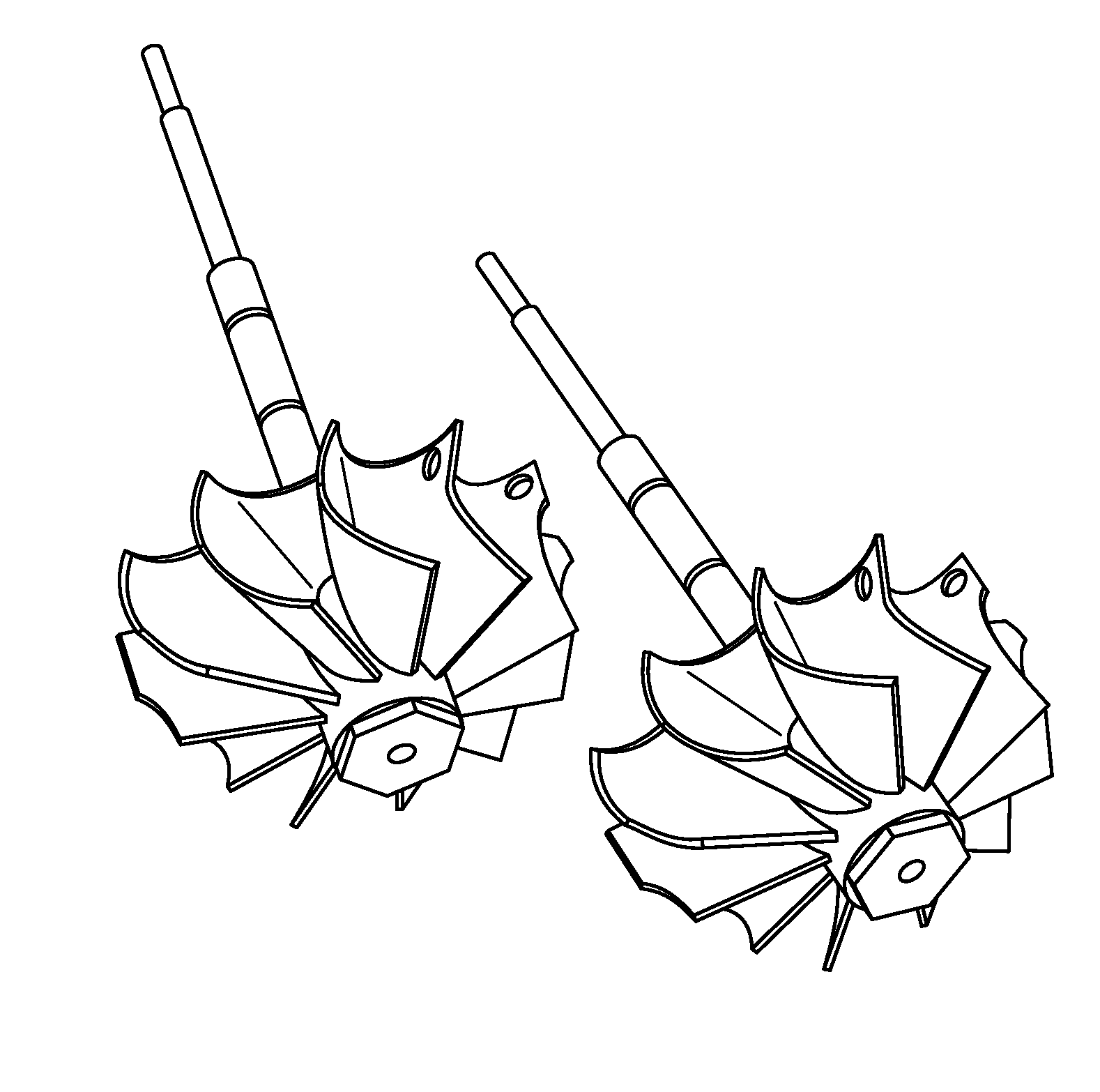

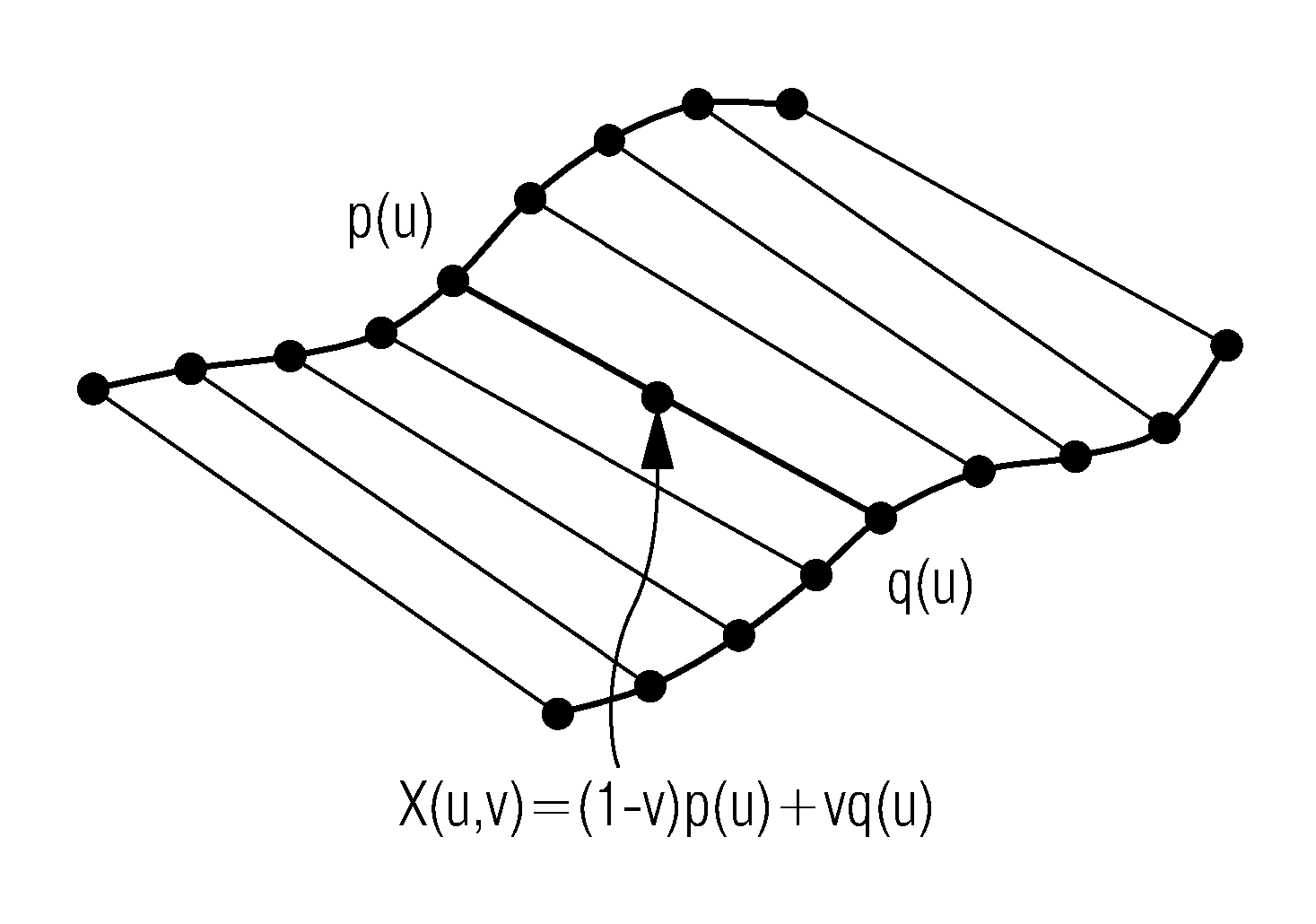

[0047] figure 1An example of a ruled surface is shown. Regular surfaces are defined in terms of surfaces that can be covered by the movement of straight lines in Euclidean space. Regular surfaces can be produced easily and cost-effectively. Ruled surfaces appear in many manufacturing processes.

[0048] Regular surfaces are the preferred choice for fabrication. A regular surface is a special type of surface that can be produced by moving straight lines through space. Regular surfaces arise in different applications such as electrical discharge processing (EDN) of wires and laser cutting where the cutting tool is controlled as a moving straight line. Furthermore, it is known that ruled surfaces are efficiently manufactured using the side-cutting method in CNC processing. Approximating free-form surfaces to regular surfaces is a typical design strategy to reduce manufacturing costs. There is therefore a need in the industry for efficient ruled surface approximation algorit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com