Method for storing tobacco leaves by way of mechanical regulation and manual nitrogen charging

A technology of tobacco leaves and machinery, which is applied in the field of artificial nitrogen storage of tobacco leaves and mechanical regulation, which can solve the problems of tobacco leaf insect infection, tobacco leaf infestation, and social development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A method for mechanically regulating and artificially filling tobacco leaves with nitrogen, comprising the steps of:

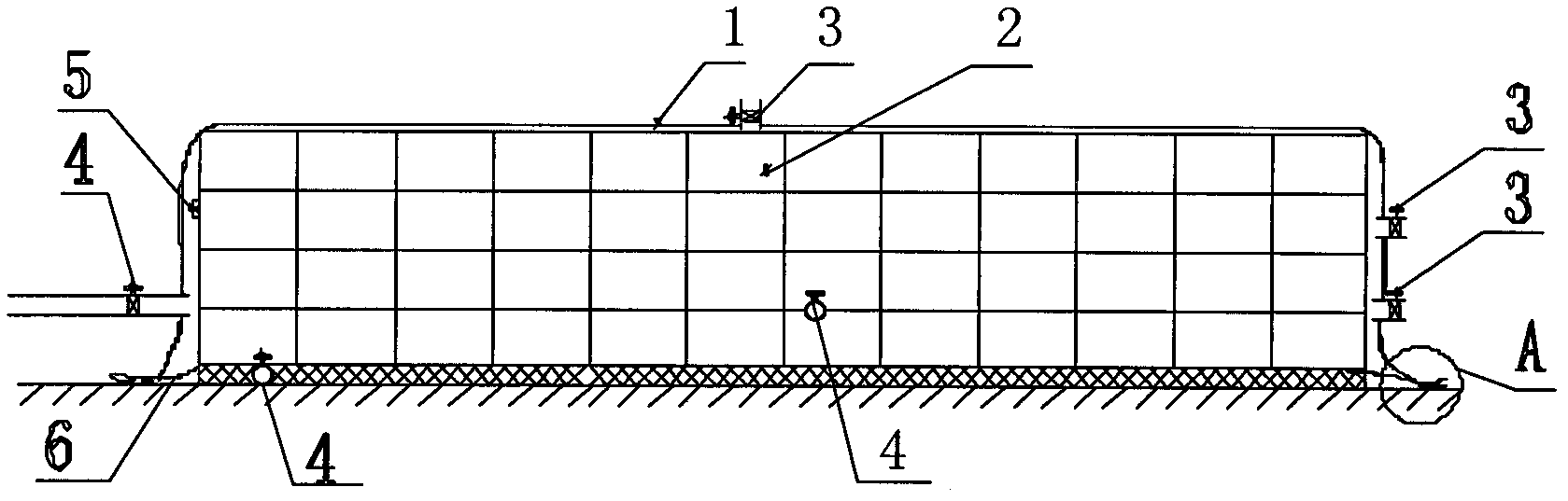

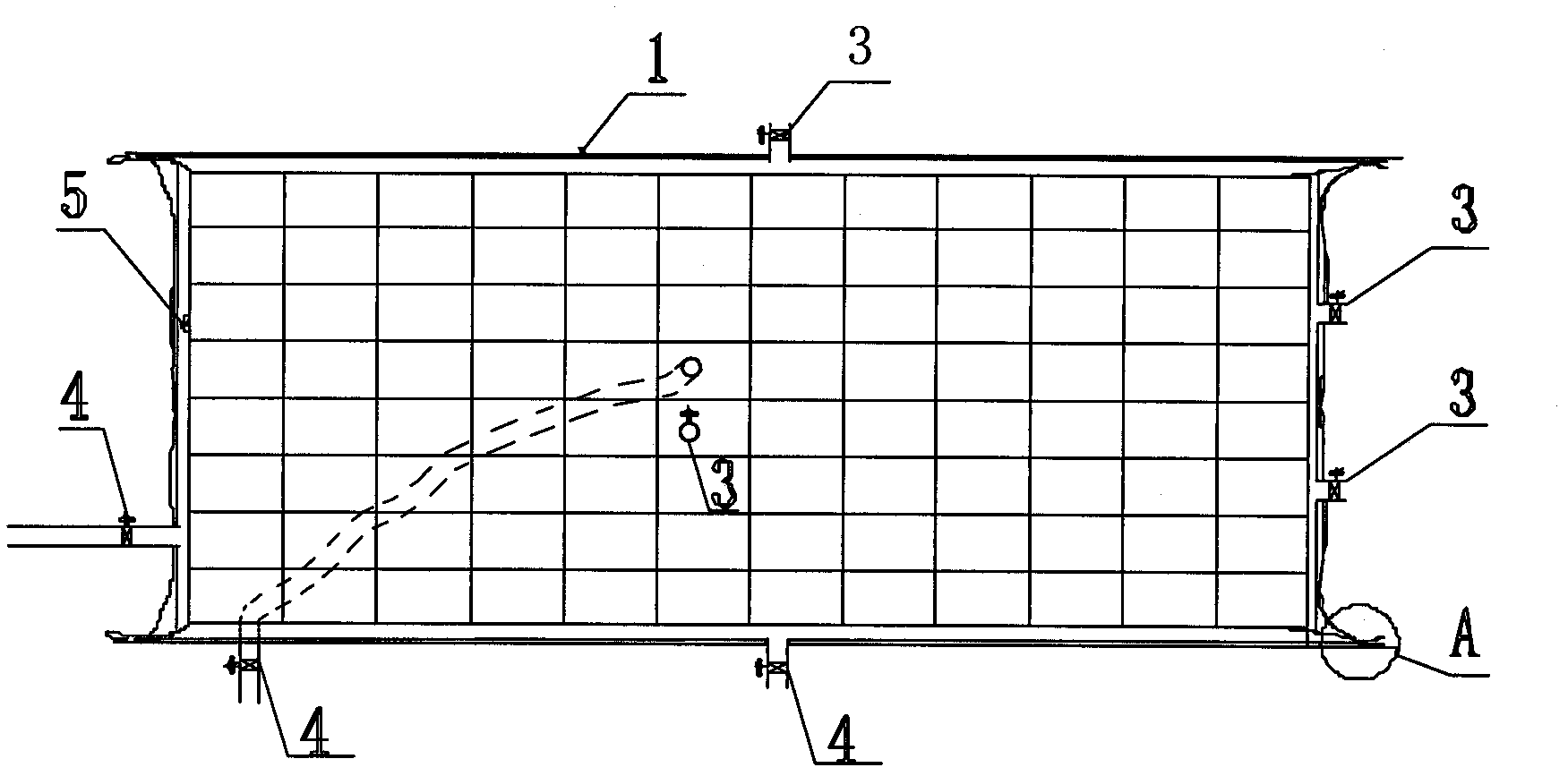

[0063] 1), build a six-sided sealed tobacco leaf stacking sealed space that can mechanically regulate the storage environment (such as Picture 1-1 , Figure 1-2 , figure 2 shown):

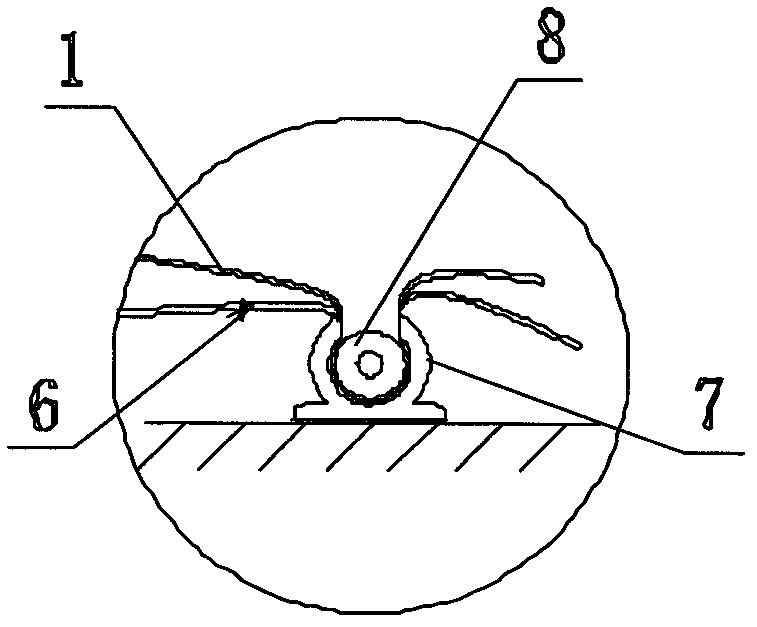

[0064] According to the expected size of the stacking area on the ground for stacking tobacco leaves, use plastic film to make a square plastic backing cloth 6 with a square area larger than the size of the stacking area and pave it on the warehouse floor, and then stack tobacco leaves on the plastic backing cloth. 2; use the plastic film to make a plastic airtight tent 1 according to the size of the stacked tobacco leaves, and cover the plastic airtight tent 1 on the tobacco leaf stack 2, and the skirt edge near the ground around the plastic airtight tent 1 and the plastic backing cloth 6 The stacked tobacco leaves 2 are wrapped in the sealed space formed by the plastic...

Embodiment 2

[0087] It is basically the same as Example 1, except that step 2) carries out a thorough nitrogen-filling fumigation control to tobacco leaf insects and mildew:

[0088] Use a mixed gas filled with nitrogen and carbon dioxide for fumigation control: connect the nitrogen generator and the carbon dioxide generator with the air intake control joint 3 on the plastic airtight tent or the plastic backing cloth 6, open the air intake control joint 3 and the air outlet control joint 4. Turn on the nitrogen generating device and the carbon dioxide generating device, input the mixed gas of nitrogen and carbon dioxide into the sealed space formed by the plastic airtight tent 1 and the plastic backing cloth 6, and replace the air in the tobacco leaf stack 2 at the same time, so that the sealed tobacco leaf stack The concentration of various gas components in the stack gradually reaches:

[0089] The volume percentage concentration of nitrogen is 85-97%, and the volume percentage concentra...

Embodiment 3

[0093] It is basically the same as Example 1, except that step 2) carries out a thorough nitrogen-filling fumigation control to tobacco leaf insects and mildew:

[0094] Use a mixed gas filled with nitrogen and carbon dioxide for fumigation control: connect the nitrogen generator and the carbon dioxide generator with the air intake control joint 3 on the plastic airtight tent or the plastic backing cloth 6, open the air intake control joint 3 and the air outlet control joint 4. Turn on the nitrogen generating device and the carbon dioxide generating device, input the mixed gas of nitrogen and carbon dioxide into the sealed space formed by the plastic airtight tent 1 and the plastic backing cloth 6, and replace the air in the tobacco leaf stack 2 at the same time, so that the sealed tobacco leaf stack The concentration of various gas components in the stack gradually reaches:

[0095] The volume percentage concentration of nitrogen is 70-85%, and the volume percentage concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com