Tobacco leaf pretreatment method during tobacco primary processing

A production process and pretreatment technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of tobacco leaf miscellaneous gas and irritation, affect workshop operation efficiency, and affect cigarette quality, so as to improve the quality of sensory evaluation and save Effects of reducing working time and storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

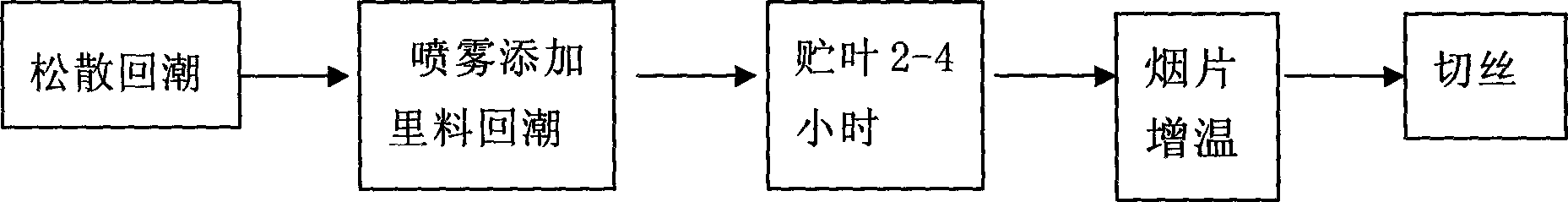

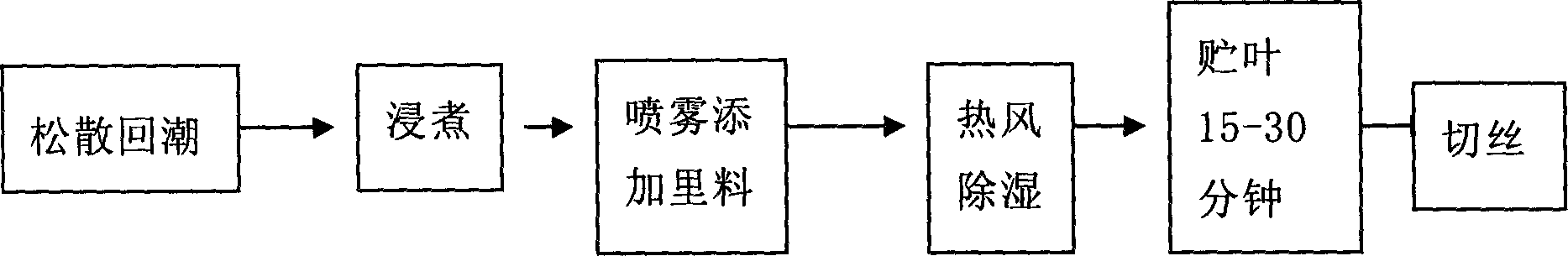

[0033] Such as figure 2 and image 3 Shown, the tobacco leaf pretreatment method in the present embodiment tobacco shredded production process, it comprises the following steps:

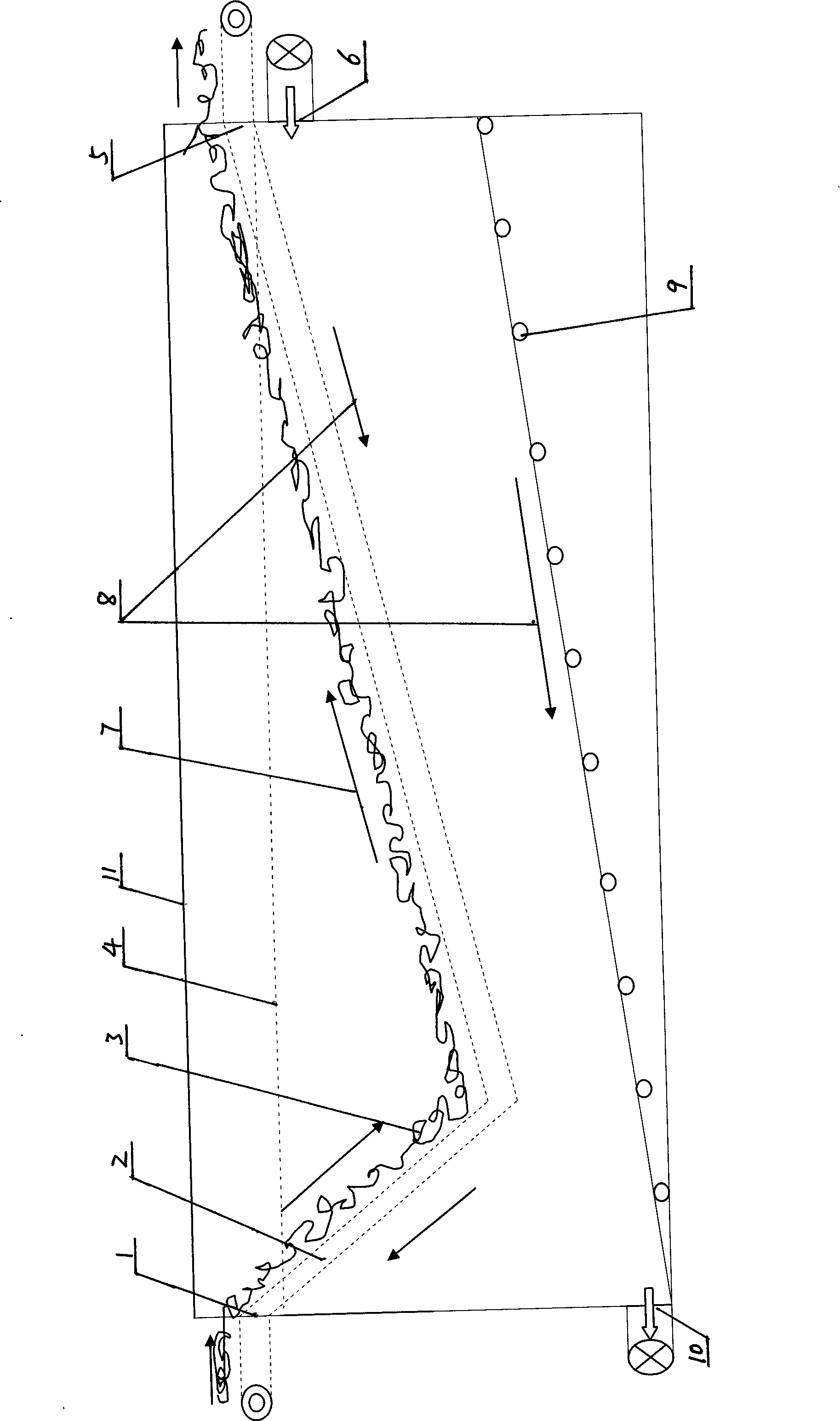

[0034] (1) Loosen and regain moisture in the laminar tobacco.

[0035] (2) Digest the loose and rehydrated tobacco leaves through the steeping equipment. According to the different grades of the tobacco leaves, the hot water temperature of the steeping equipment is set at any temperature between 70-100°C, and the tobacco leaves are transported to the In the soaking equipment, after soaking in hot water for any time between 5-15 minutes, it is then transported to the spiral draining device for draining. The immersion equipment includes a hot water tank 11, one end of the upper part of the hot water tank 11 is provided with a stainless steel mesh conveyor belt inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com