Reel material printer pre-positioning automatic overprinting system and automatic overprinting method

A printing machine and pre-positioning technology, applied in printing machines, general parts of printing machinery, printing, etc., can solve the problem that the photoelectric sensor cannot detect the overprinting standard line of the same color or similar color, cannot print the overprinting standard line, and cannot use it. Problems such as automatic overprinting system, to achieve the effect of simplifying the interference of unpredictable factors and simple and reliable control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

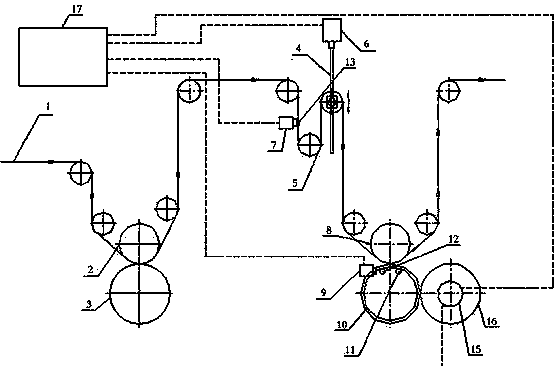

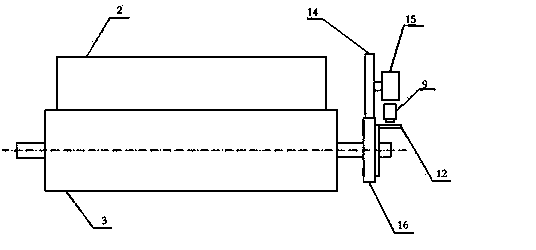

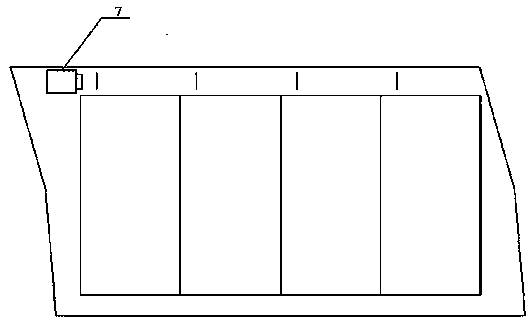

[0023] Embodiment 1: with reference to attached Figure 1-4 . A pre-positioning automatic overprinting system for a web printing machine, comprising a control system 17, a first printing unit to an Nth printing unit, an overprinting motor 6 is provided between the first printing unit and the Nth printing unit, and the overprinting motor 6 and The overprint screw 4 is connected to and drives the overprint screw 4 to rotate, and the overprint adjustment roller 5 is driven by the overprint screw 4 to move up and down to adjust the overprint error between the nth color and the first color. There is a photoelectric sensor A7, and the signal output end of the photoelectric sensor A7 is connected to the signal end of the controller 17 through a connecting line; the first signal rod 11 and the second signal rod 12 are installed at the distance between the end faces of the printing plate transmission gear 16 in the Nth printing unit, A rotary encoder 15 is installed in the center of t...

Embodiment 2

[0024] Embodiment 2: On the basis of Embodiment 1, a pre-positioning automatic overprinting method of a web printing machine, using the overprint adjustment roller set by the control system of the printing press at low speed to manually adjust and adjust manually (strobe can be used) instrument, still image system, etc.) overprint adjustment, when the overprint error reaches zero visually, the photoelectric sensor recorded by the rotary encoder at this time detects the signal position of the standard color mark line, the signal position of the second signal rod, and the virtual registration of the printing plate cylinder The center position is identified as the exact position where the overprint error is zero, and the control system records its position; if the overprint exact position drifts, or a more precise overprint exact position is required, the virtual center pulse position ( At the same time, select the standard color line signal between the areas with less pulse signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com