Anti-oxidizing paint for electrolytic aluminum anode carbon blocks and preparation method thereof

An anti-oxidation coating and electrolytic aluminum anode technology, applied in the field of electrolysis, can solve the problems of high production cost, limited physical and chemical state of raw materials, etc., and achieve the effects of low production cost, cheap and easy-to-buy materials, and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The electrolytic aluminum anode carbon block anti-oxidation coating is composed of the following raw materials in weight percentage: 35% of borax or boric acid, 15% of kaolin, 30% of industrial phosphoric acid, 5% of industrial aluminum sulfate, and 15% of water. Described borax or boric acid is a first-grade product, and Al in kaolin 2 o 3 ≥35%, Fe 2 o 3 ≤1%, H in industrial phosphoric acid 3 PO 4 >85%, Al in industrial aluminum sulfate 2 o 3 ≥15%, Fe≤0.03%.

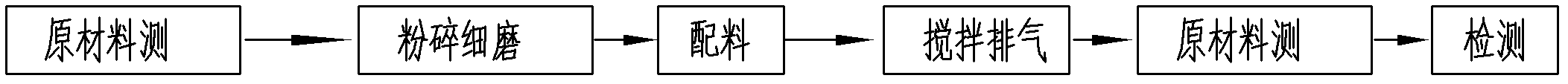

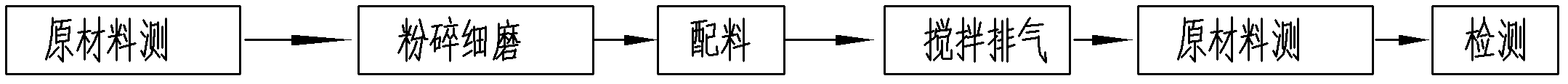

[0014] The preparation method is as follows: put 35% of borax or boric acid, 15% of kaolin and 5% of industrial aluminum sulfate into the wheel mill; mix 30-35% of industrial phosphoric acid and 10-15% of water , take 1 / 3 of the amount and put it into the wheel mill, wet mix it evenly and release the material, after aging for 24 hours, then add the aged slurry and the mixture of the remaining 2 / 3 of the industrial phosphoric acid and water into the ball mill at one time Within, grind for 2 hours and relea...

Embodiment 2~5

[0016] See Table 1 for the raw material proportions of the anti-oxidation coatings for electrolytic aluminum anode carbon blocks described in Examples 2-5.

[0017] Raw material ratio (weight percent, %) of electrolytic aluminum anode carbon block anti-oxidation coating in the embodiment 2~5 of table 1

[0018] Example 2

[0019] The preparation method of the electrolytic aluminum anode carbon block anti-oxidation coating described in Examples 2-5 is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com