Spraying apparatus for metal-organic chemical vapor deposition equipment

A chemical vapor deposition and organic compound technology, which is applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor uniform mixing effect and achieve uniform mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

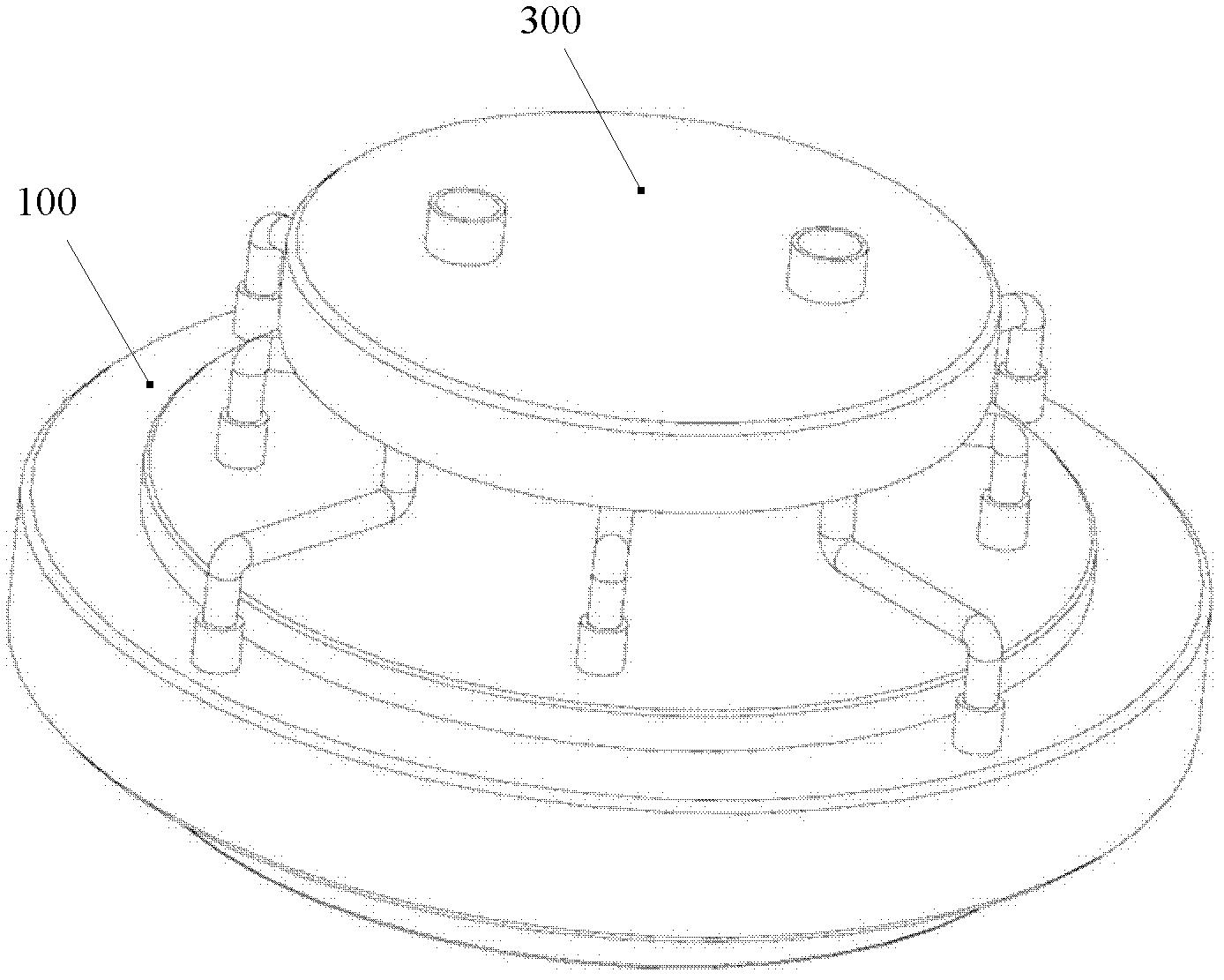

[0035] Figure 1A It is a schematic diagram of the connection structure between the embodiment of the present invention and the gas distribution unit. A gas distribution unit 300 is connected to the upper end of the shower device used in metal organic compound chemical vapor deposition equipment of the present invention.

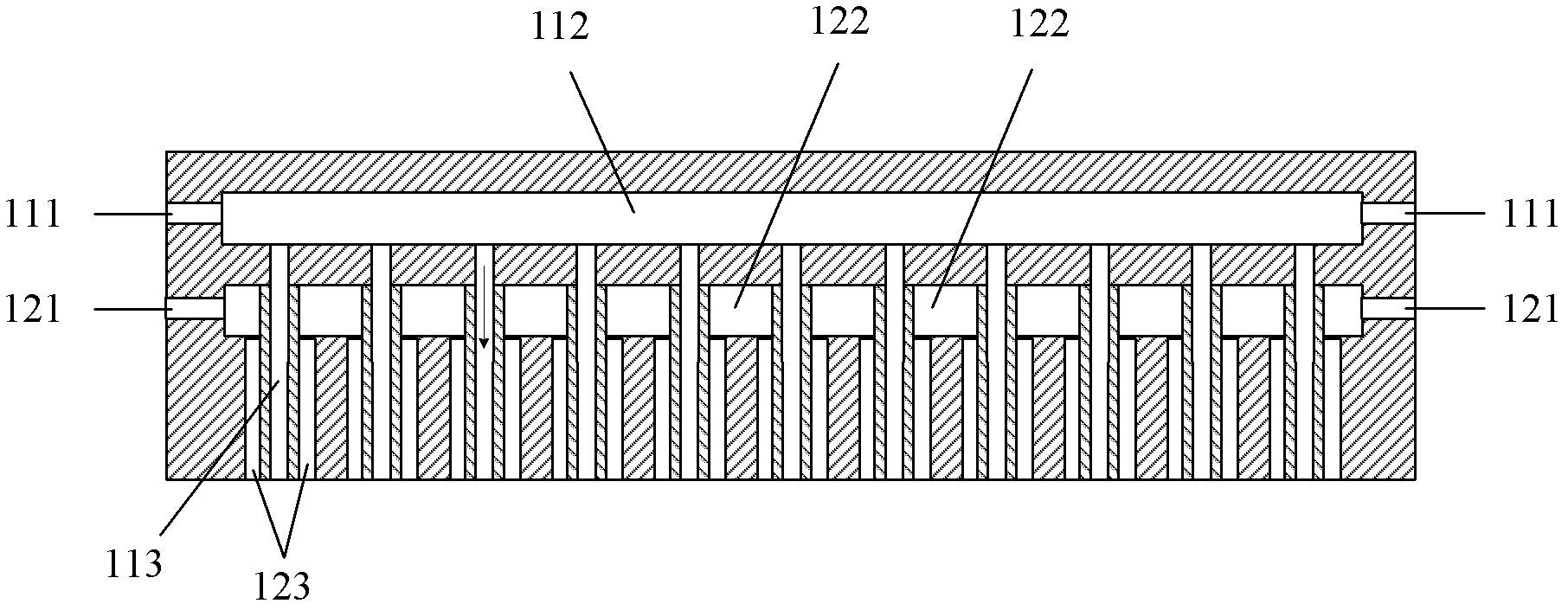

[0036] Figure 1B It is a sectional view of Embodiment 1 of the present invention.

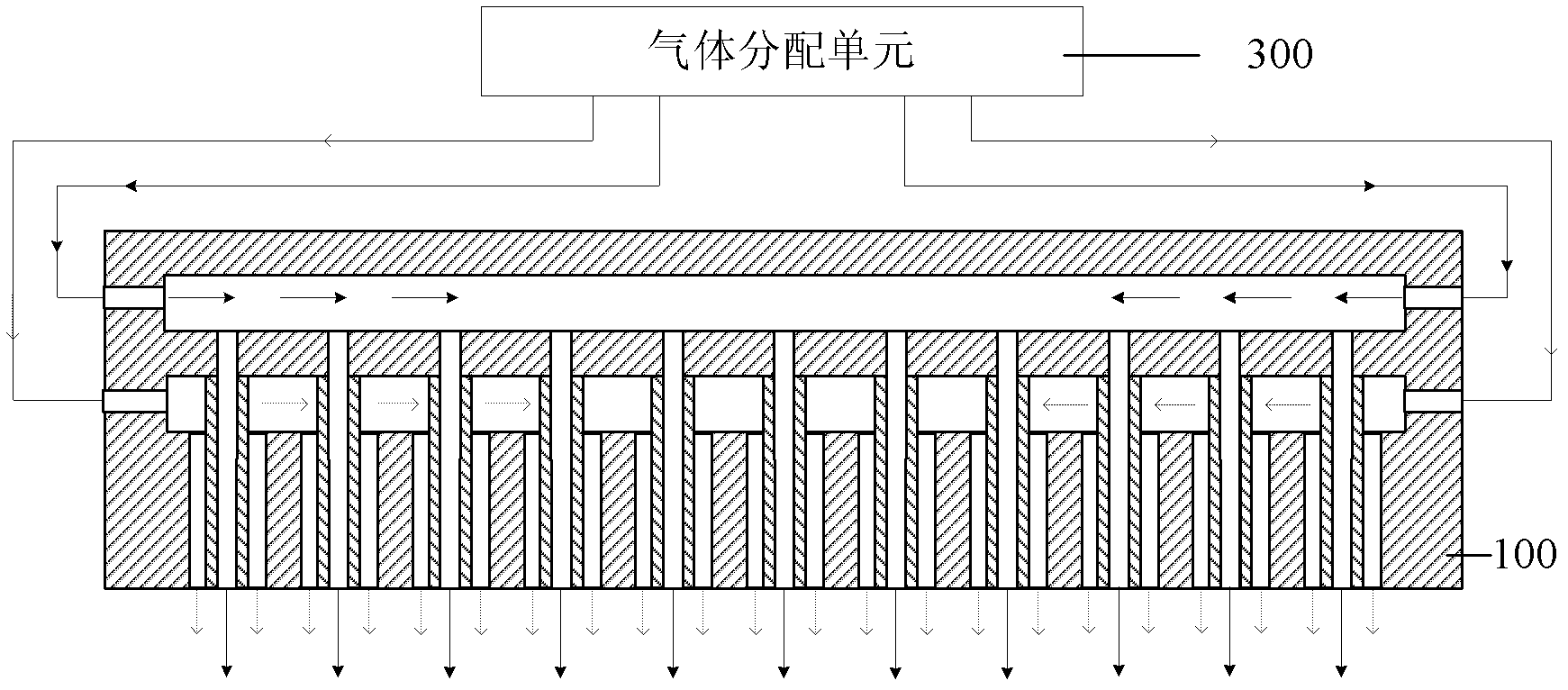

[0037] Figure 1C It is a schematic diagram of gas flow in Example 1 of the present invention.

[0038] Figure 2A It is a schematic diagram of a partial cross-sectional structure of Embodiment 1 of the present invention.

[0039] Figure 2B It is a top sectional view of nested structures arranged in parallel in Embodiment 1 of the present invention.

[0040] Please refer to Figure 1A , 1B , 1C, 2A, 2B, this embodiment 1 is used for the spraying device of metal organic compound chemical vapor deposition equipment, using two conveying channels, including a first air i...

Embodiment 2

[0049] Figure 3A It is a schematic diagram of a partial cross-sectional structure of Embodiment 2 of the present invention.

[0050] Figure 3B It is a top sectional view of nested structures arranged radially in Embodiment 2 of the present invention.

[0051] Please refer to Figures 3A to 3B , this embodiment 2 is improved on the basis of embodiment 1, and the difference is that: the second through holes 123 are arranged in a radial structure instead of in a parallel structure.

[0052] For the nested structure of Example 2, please refer to Figure 3A The part in the dotted box and Figure 3B .

Embodiment 3

[0054] Figure 4 It is a top sectional view of a nested structure arranged in a circle in Embodiment 3 of the present invention. Embodiment 3 is improved on the basis of Embodiment 1 or 2, and the difference is that: the second through holes 123 are arranged in a circular structure instead of radial or parallel. That is, the second through hole 123 expands outward round by round. The first through holes 113 are evenly distributed in the second through holes 123 in each circle.

[0055] Figure 5 It is a three-dimensional schematic diagram of the nested structure of the above two or three embodiments 1, 2 and 3. Please refer to Figure 5 , the nested structure of each second through hole 123 and its corresponding plurality of first through holes 113 , that is, each second through hole 123 nests a plurality of first through holes 113 . The first through hole 113 may be a circular hole, a square hole or a triangle, etc., and the second through hole 123 is a slot-shaped hole....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com