Surface water conductivity non-contact measurement device and method

A non-contact measurement and water conductivity technology, applied in measurement devices, measurement of electrical variables, measurement of resistance/reactance/impedance, etc., can solve the problems of heavy maintenance burden, oxidation and corrosion, and the need for regular cleaning to reduce maintenance work. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

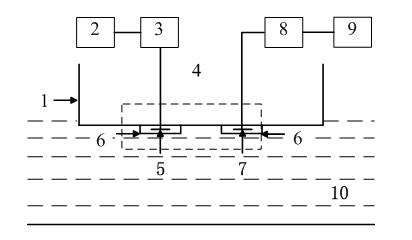

[0031] Such as figure 1 As shown, the non-contact measurement device for surface water conductivity includes a buoyancy tank 1 , an AC excitation source 2 , an inductance module 3 , a detection module 4 and a signal processing circuit 8 . The detection module 4 includes an excitation electrode 5 , a detection electrode 7 and an insulating layer 6 attached to the outer bottom of the buoyancy tank. The electrodes are separated from the water by a thin insulating layer 6 . The AC excitation source 2 is connected to the excitation electrode 5 via the inductance module 3 , the detection electrode 7 is connected to the signal processing circuit 8 , and the signal processing circuit 8 is connected to the data acquisition and processing system 9 .

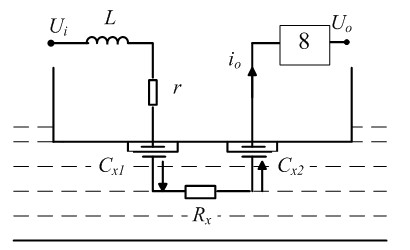

[0032] Such as figure 2 As shown, the equivalent circuit diagram of the non-contact measurement of surface water conductivity is: the output terminal of the first operational amplifier of the AC excitation source 2 is connected to one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com