Heat dissipating device for machine cabinet

A technology of cooling device and cabinet, applied in the field of cooling device of cabinet, can solve the problems of high noise, low safety factor and high failure rate, and achieve the effects of easy maintenance, saving energy consumption and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described now in conjunction with accompanying drawing.

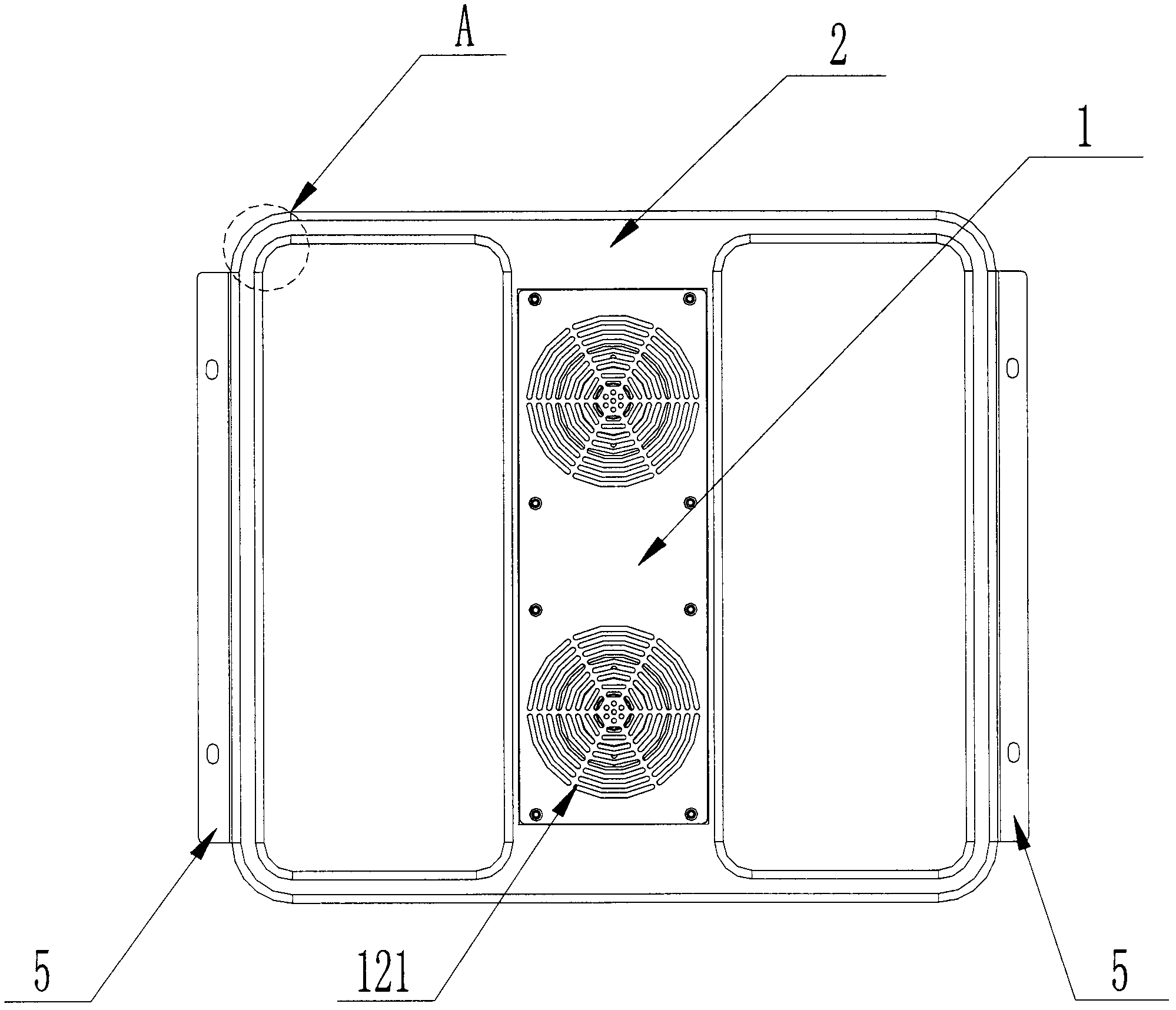

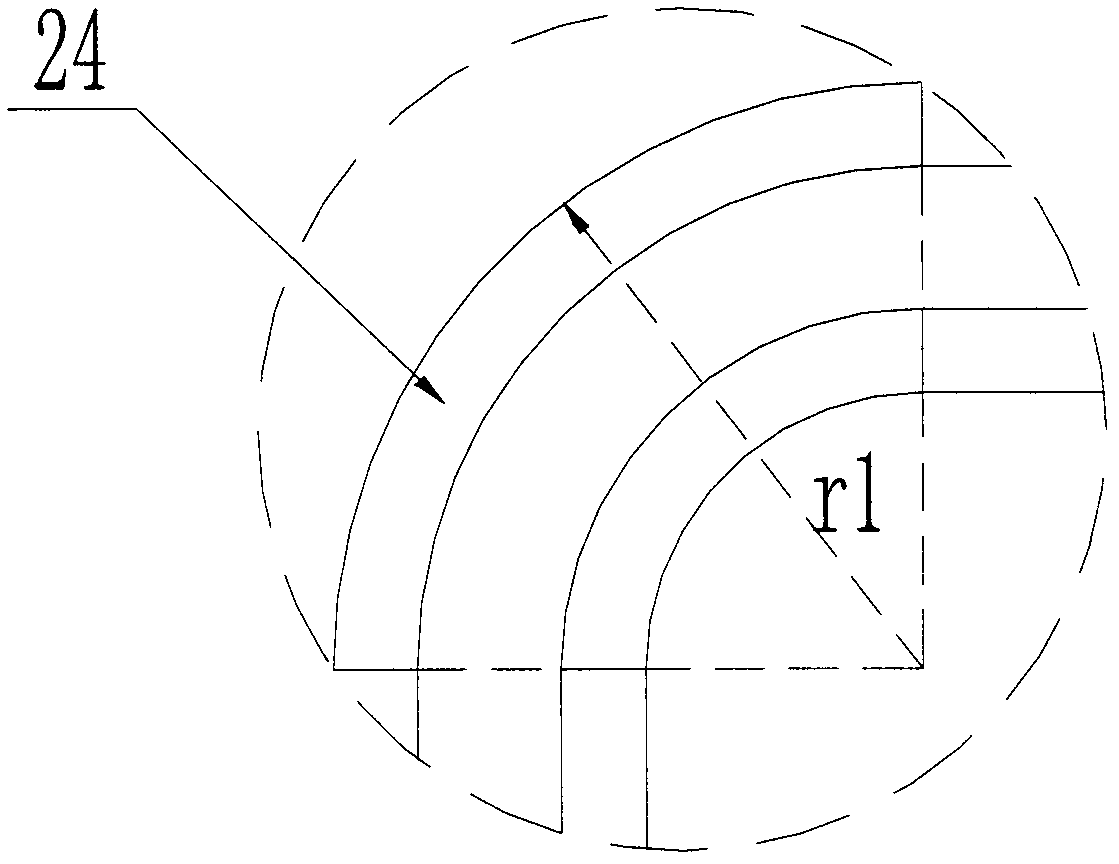

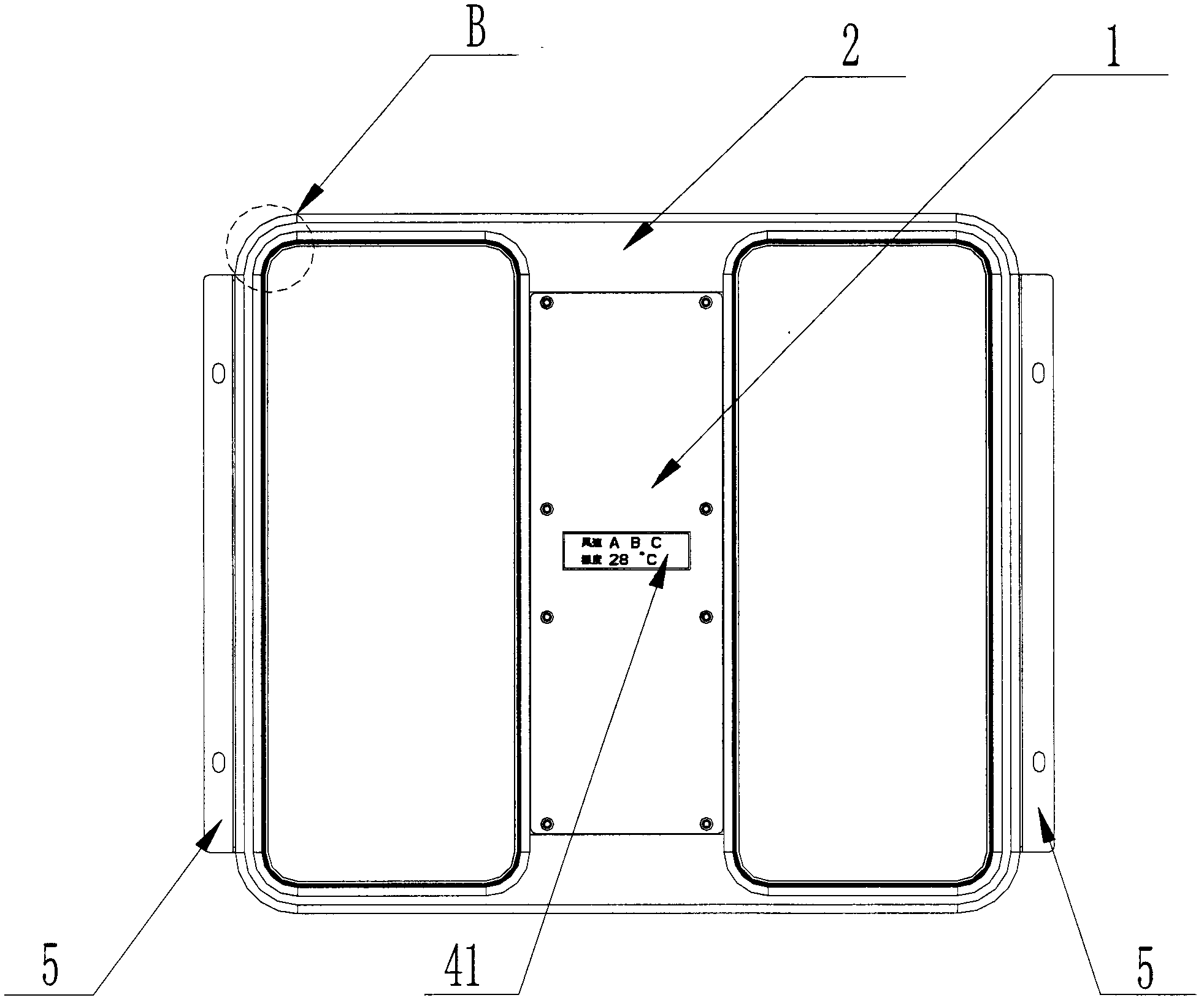

[0030] The present invention includes a main air duct 1, a static pressure chamber 2, a nozzle 3 and an intelligent display management module 4 provided with a power supply assembly. Such as figure 1 , image 3 and Figure 5 As shown, the main air duct 1 and the static plenum 2 are connected to each other, the static plenum 2 is an annular static plenum, and the left and right respectively form annular first air ducts and second air ducts 21, 22, and the center of the static plenum 2 is set There is a hollow part corresponding to the shape and size of the main air duct 1. The main air duct 1 is placed in the hollow part and communicated with the static pressure chamber 2. The inside of the static pressure chamber 2 is connected to the main air duct 1. There are two arc-shaped acute-angle air deflectors 25 with a radius of r2=20-30mm in opposite directions, and there are fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com