Waste stone powder recycling method for sandstone producing system by wet method

A technology for waste stone powder and production wastewater, applied in wet separation, chemical instruments and methods, solid separation, etc., can solve the problems of not polluting air, wasting resources, etc., and achieve the effect of effective use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

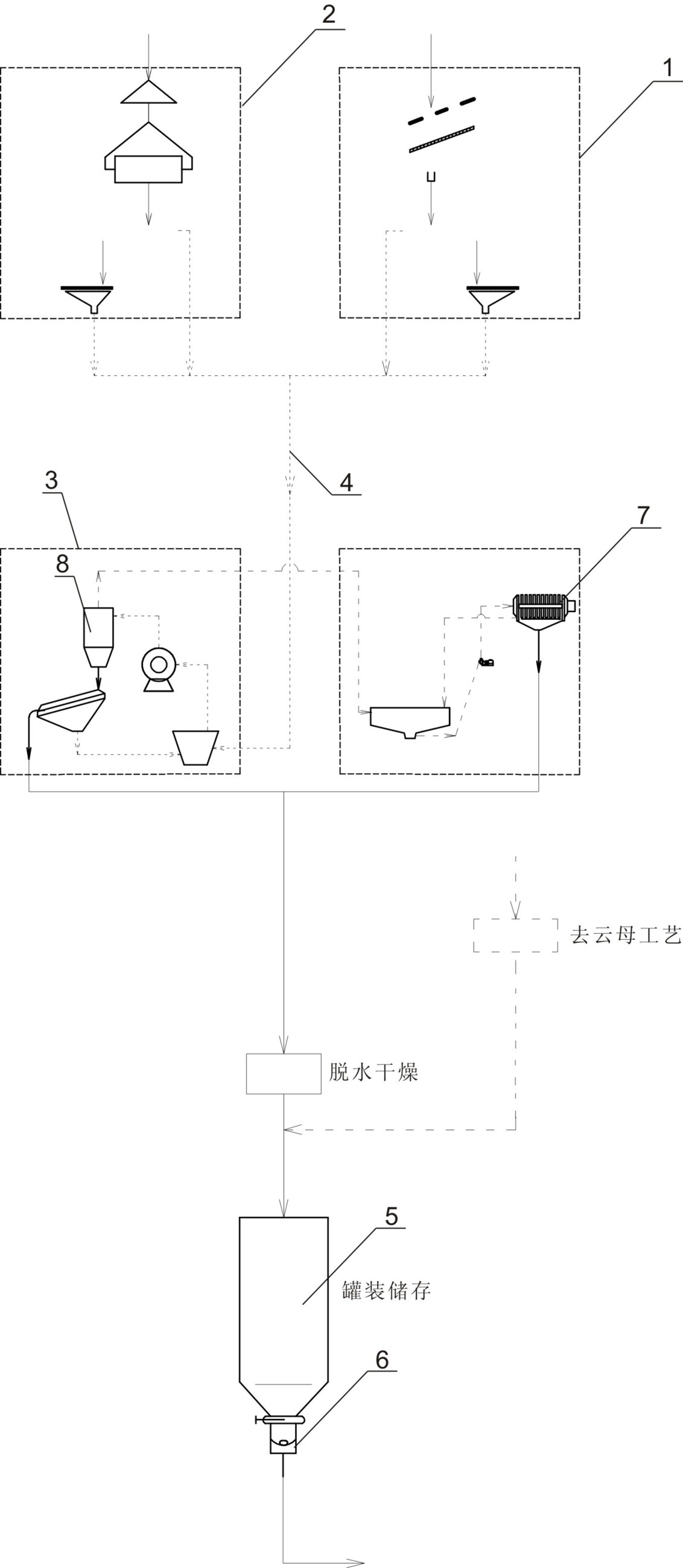

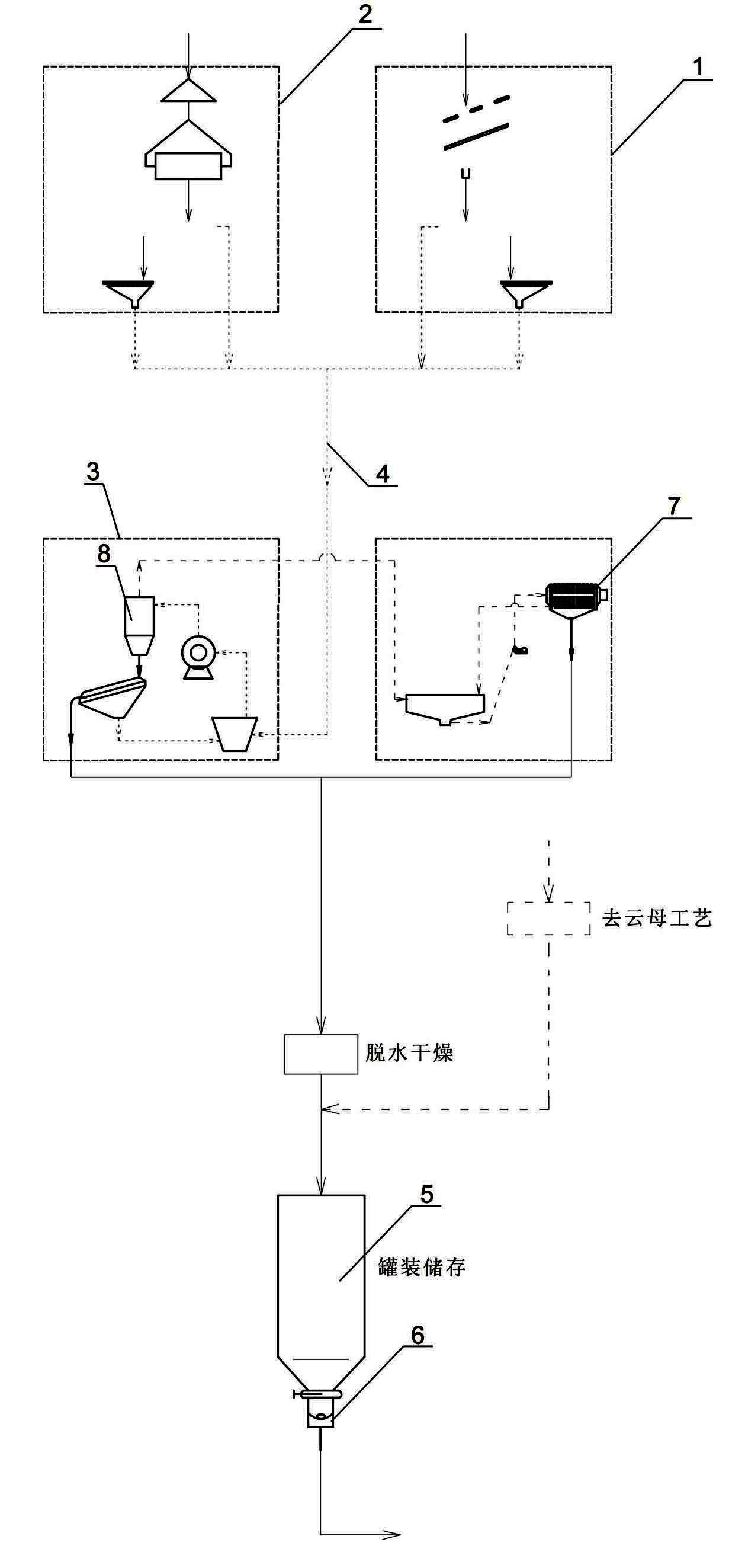

[0017] Such as figure 1 As shown, a method for reusing waste stone powder in a wet sand production system is characterized in that the method includes the following steps:

[0018] 1) Separate the production wastewater channels of the screening workshop, stone washing workshop and sand washing workshop used for the initial washing of wool in the wet sand production system, and discharge the wastewater directly, and do not use the stone powder contained in the wastewater in the channels;

[0019] 2) Summarize the wet production wastewater channels 4 of the screening workshop 1, sand washing workshop 2, washing workshop, and recycling workshop 3 used for production in the wet sand production system, and recycle the stone powder contained in the wastewater;

[0020] 3) Recover the stone powder in the sand scraping machine, filter press 7 and stone powder recovery device 8 in the wet sand production system, as well as the redundant stone powder that is discarded after adding stone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com