Manufacturing process for non-magnetic Cu-base alloy basebands in strong cubic texture

A strong cubic texture, non-magnetic technology, applied in metal rolling and other directions, can solve the problems of baseband grain boundary quality characterization, hysteresis loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

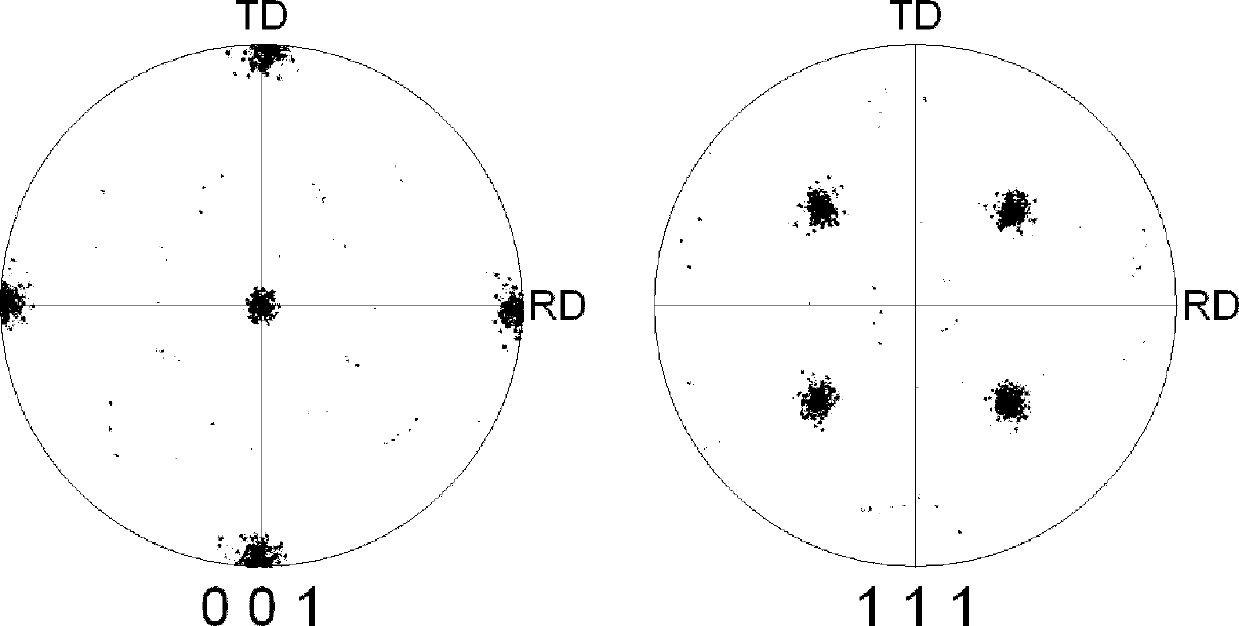

Embodiment 1

[0017] The electrolytic Cu and electrolytic Ni with a purity of 99.9% are mixed according to the weight of copper and nickel at 60:40, and the two raw materials are melted in an electromagnetic induction vacuum melting furnace to obtain Cu 60 Ni 40 Alloy initial ingot; then heat the alloy ingot at 850°C for 2 hours, then hot forge it into a 400mm, 30mm wide, and 20mm high billet, and then carry out hot rolling treatment. Rolling, the deformation of each pass is 10%, the total deformation is 30%, and finally wire-cut to obtain Cu with the dimensions of length, width and height respectively 20mm×15mm×10mm 60 Ni 40 Alloy ingots. Then it is subjected to a cold rolling treatment with a deformation amount of 5% per pass and a total deformation amount of 99%, to obtain an alloy base strip with a thickness of 100 μm. The cold-rolled base strip was placed in Ar / 4%H 2 Under the protection of mixed gas, a two-step annealing process was adopted. First, the temperature was raised to 55...

Embodiment 2

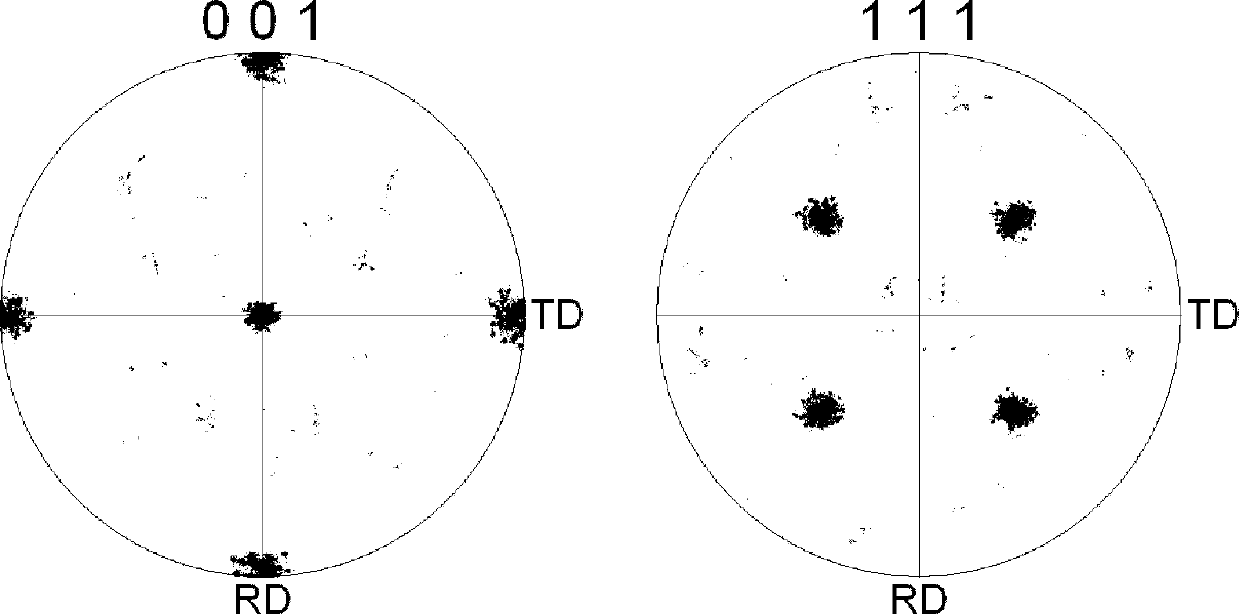

[0019] The electrolytic Cu and electrolytic Ni with a purity of 99.9% are mixed according to the weight of copper and nickel at 70:30, and the two raw materials are melted in an electromagnetic induction vacuum melting furnace to obtain Cu 70 Ni 30 Alloy initial ingot; then heat the alloy ingot at 850°C for 2 hours, then hot forge it into a 450mm, 30mm wide, and 15mm high ingot, and then carry out hot rolling treatment. Rolling, the pass deformation is 8%, the total deformation is 30%, and finally the wire cutting obtains Cu with the dimensions of length, width and height respectively 20mm×15mm×10mm 70 Ni 30 Alloy ingots. Then it is subjected to a cold rolling treatment with a deformation amount of 4% per pass and a total deformation amount of 99%, to obtain an alloy base strip with a thickness of 100 μm. The cold-rolled base strip was placed in Ar / 4%H 2 Under the protection of mixed gas, a two-step annealing process was adopted. First, the temperature was raised to 550°C ...

Embodiment 3

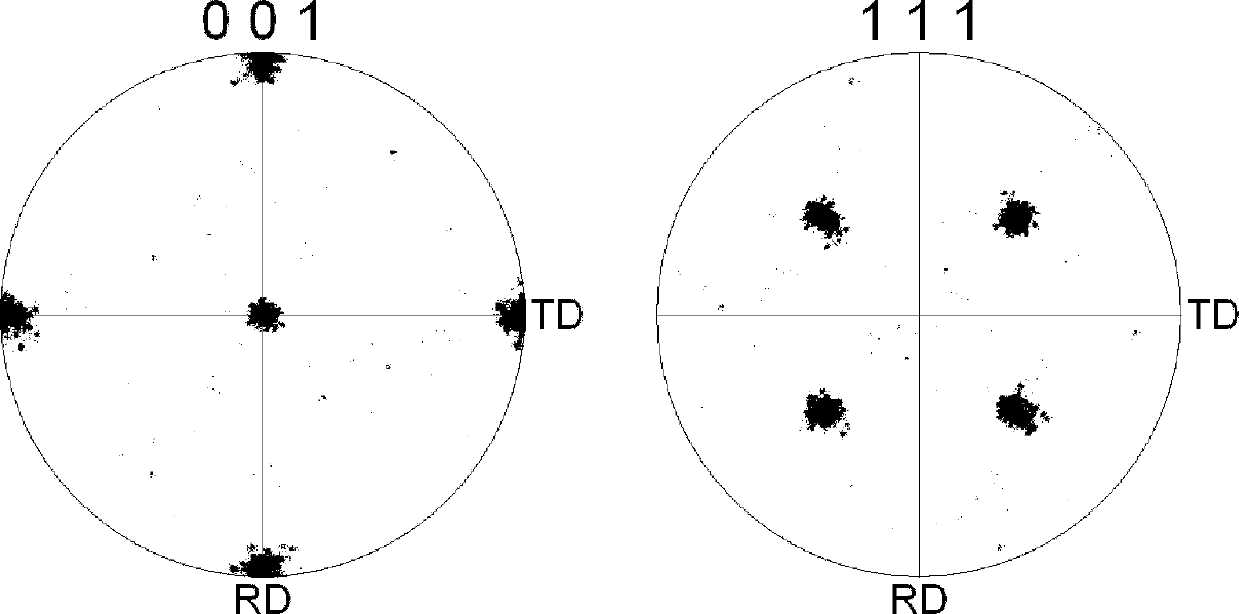

[0021] The electrolytic Cu and electrolytic Ni with a purity of 99.9% are mixed according to the weight of copper and nickel at 80:20, and the two raw materials are melted in an electromagnetic induction vacuum melting furnace to obtain Cu 80 Ni 20 Alloy initial ingot; then heat the alloy ingot at 850°C for 2 hours, then hot forge it into a 400mm, 33mm wide, and 17mm high ingot, and then carry out hot rolling treatment. Rolling, the deformation of each pass is 10%, the total deformation is 40%, and finally wire-cut to obtain Cu with the dimensions of length, width and height respectively 20mm×15mm×10mm 80 Ni 20 Alloy ingots. Then it is subjected to a cold rolling treatment with a deformation amount of 3% per pass and a total deformation amount of 99.2%, to obtain an alloy base strip with a thickness of 80 μm. The cold-rolled base strip was placed in Ar / 4%H 2 Under the protection of mixed gas, a two-step annealing process was adopted. First, the temperature was raised to 55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com