Tube expander

A tube expander and cylindrical body technology, applied in the field of tube expanders, can solve the problems of difficult coiling, limited range of applicable tube diameters, short life, etc., and achieve increased rotation flexibility, reliable production quality, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in further detail below through specific embodiments.

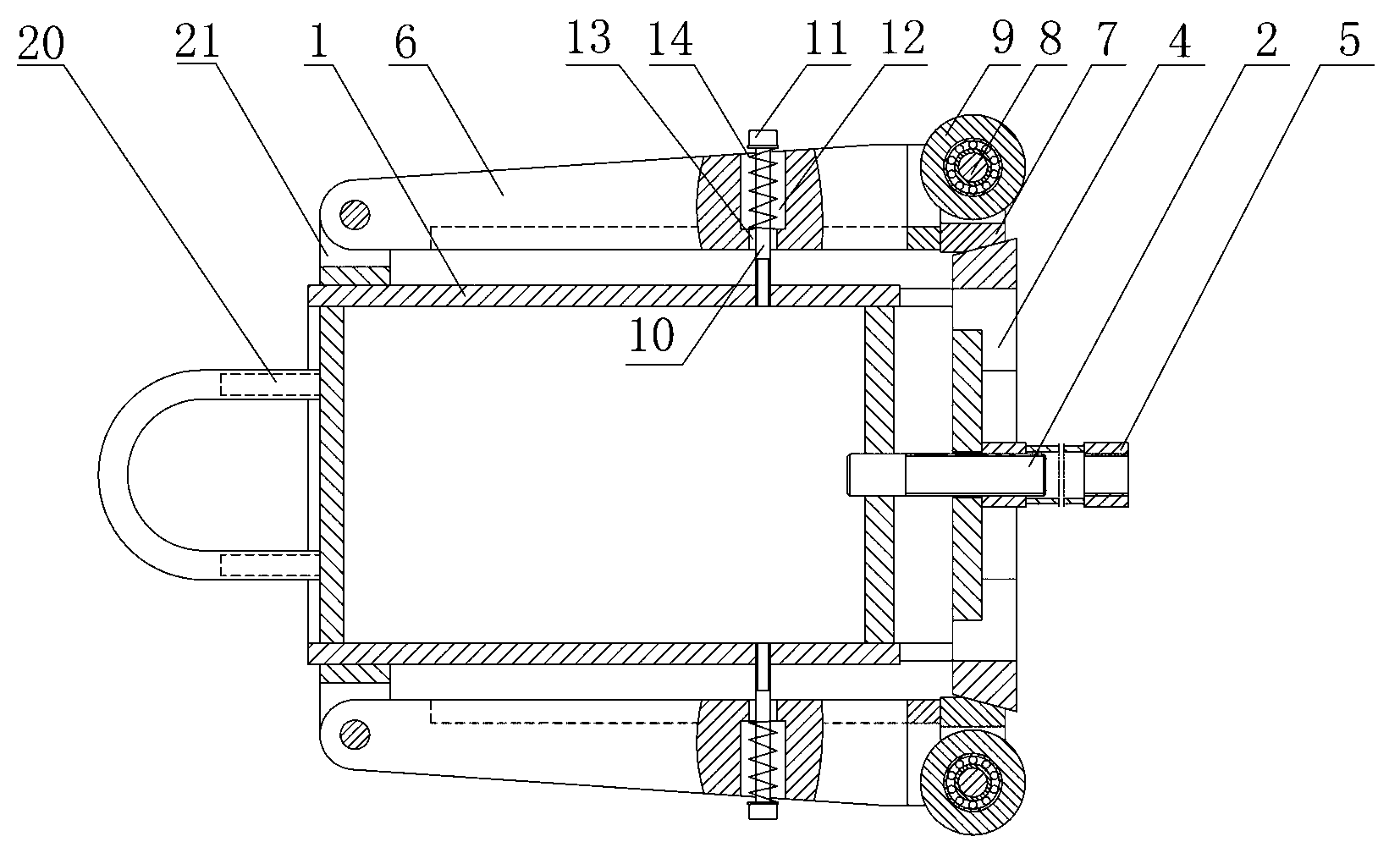

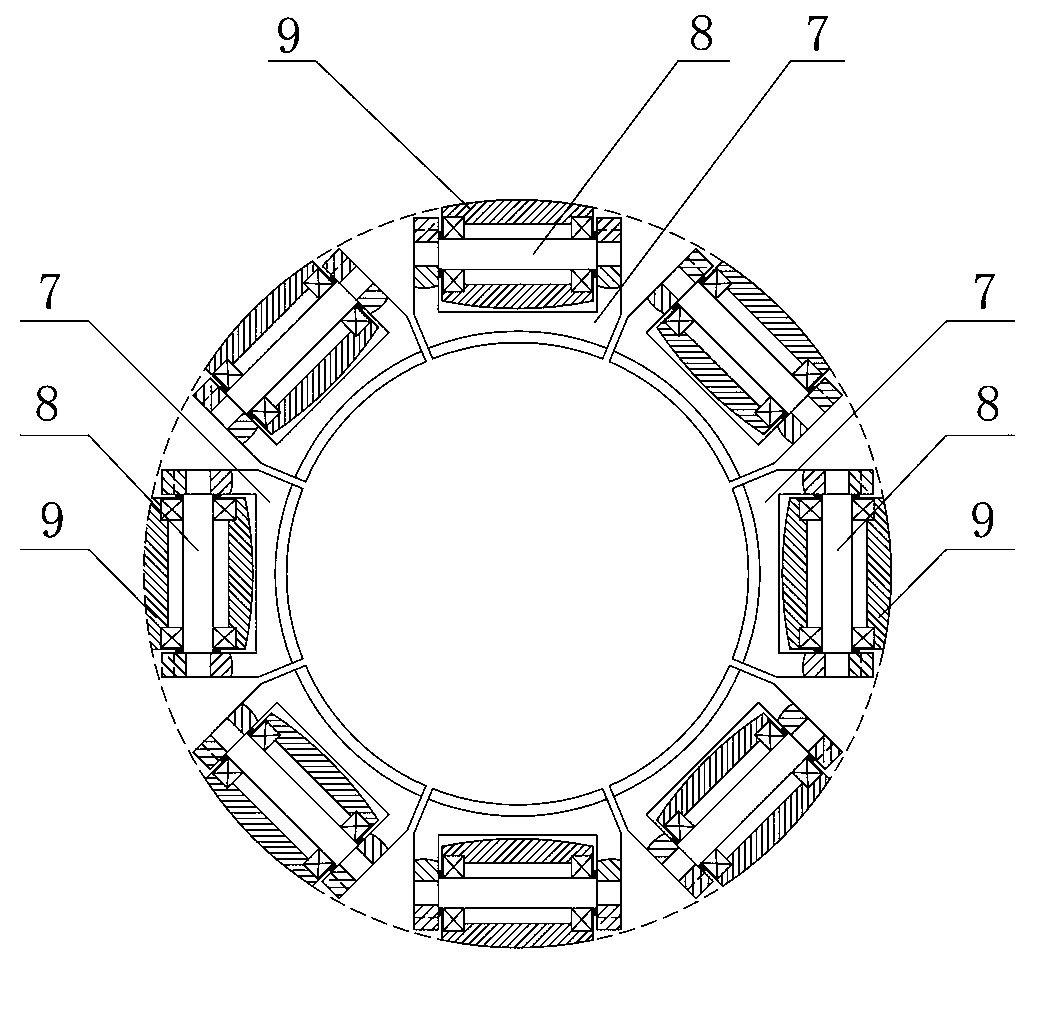

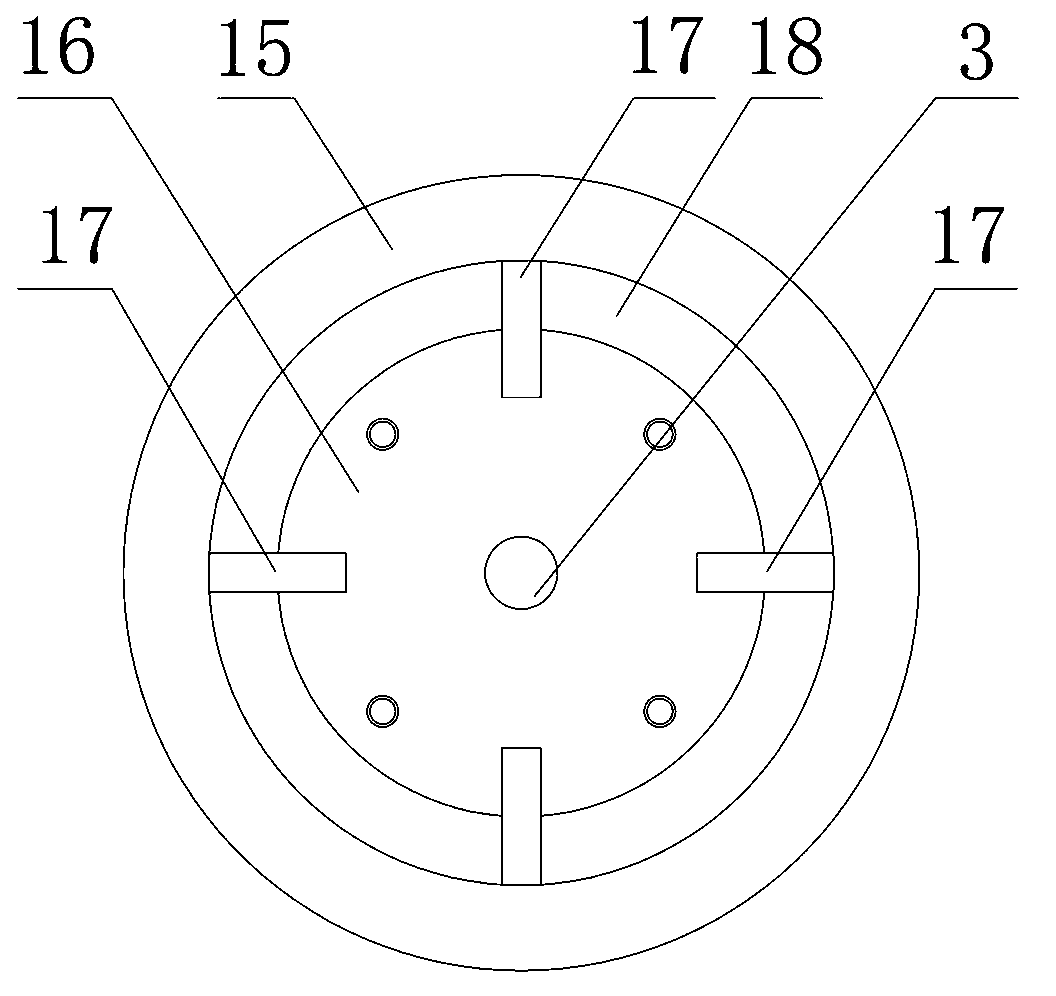

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, a tube expander includes a cylinder 1, eight groups of expanding roller structures evenly distributed on the outer surface of the cylinder 1, a lead screw 2, a cone 4 with a screw sleeve hole 3 in the center and Lead screw sleeve 5.

[0022] Wherein, the roller structure includes a swing arm 6, a roller frame 7 whose rear end is fixed to one end of the swing arm 6, a roller shaft 8 installed on the left and right side walls of the roller frame 7, and installed through bearings. The expanding roller 9 on the roller shaft 8; the expanding roller 9 is made of high-quality alloy steel and quenched.

[0023] Eight groups of swing arm seats 21 are fixed at the end of the cylinder body 1, and the eight groups of swing arm seats 21 are evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com