Automatic wire feeding mechanism of pneumatic flat screen welding machine

A wire feeding mechanism and welding machine technology, applied in the direction of online network, other household appliances, household appliances, etc., can solve the problems of inconvenient maintenance, large mechanical noise, inaccurate wire running, etc., and achieve convenient maintenance, long working time, structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

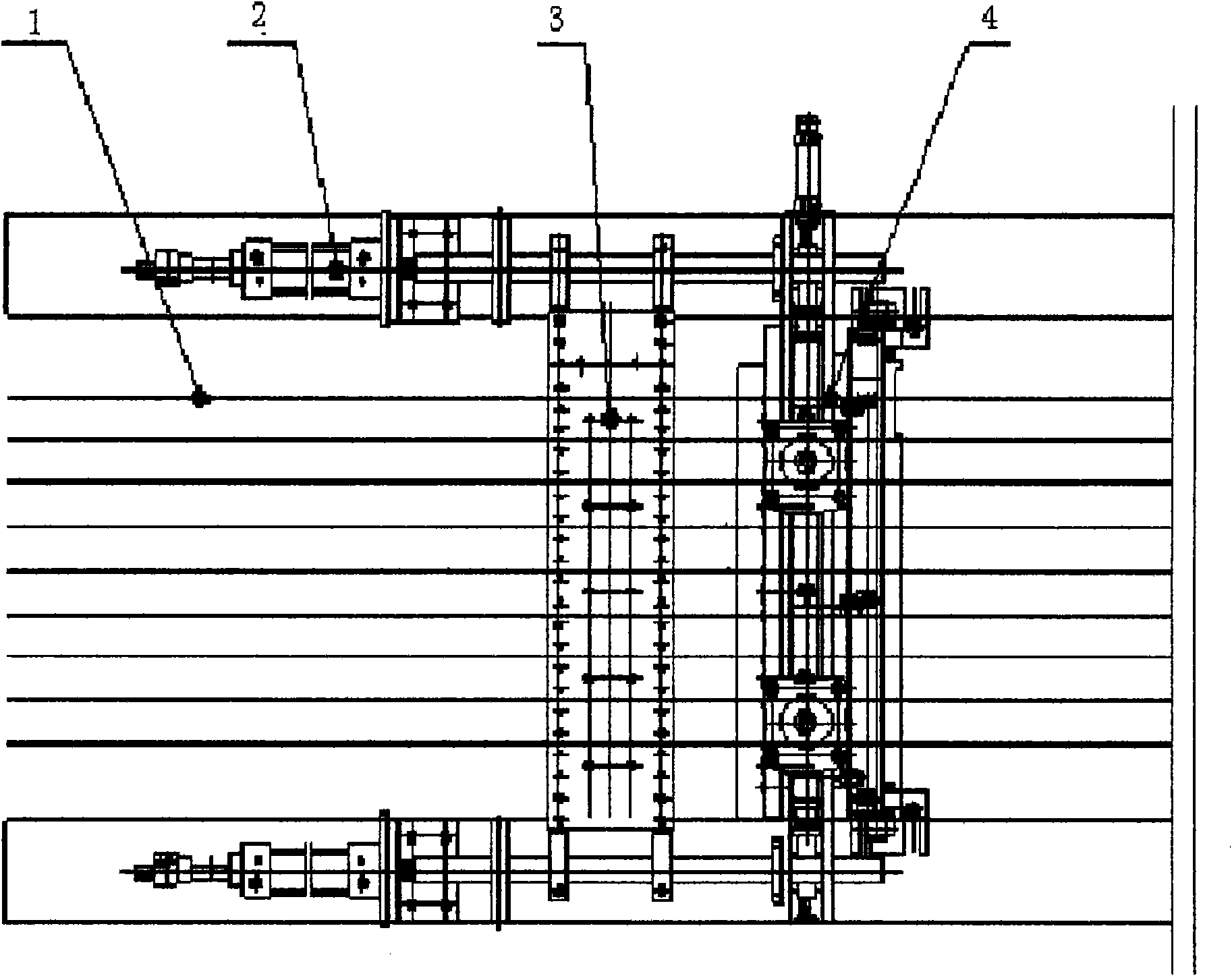

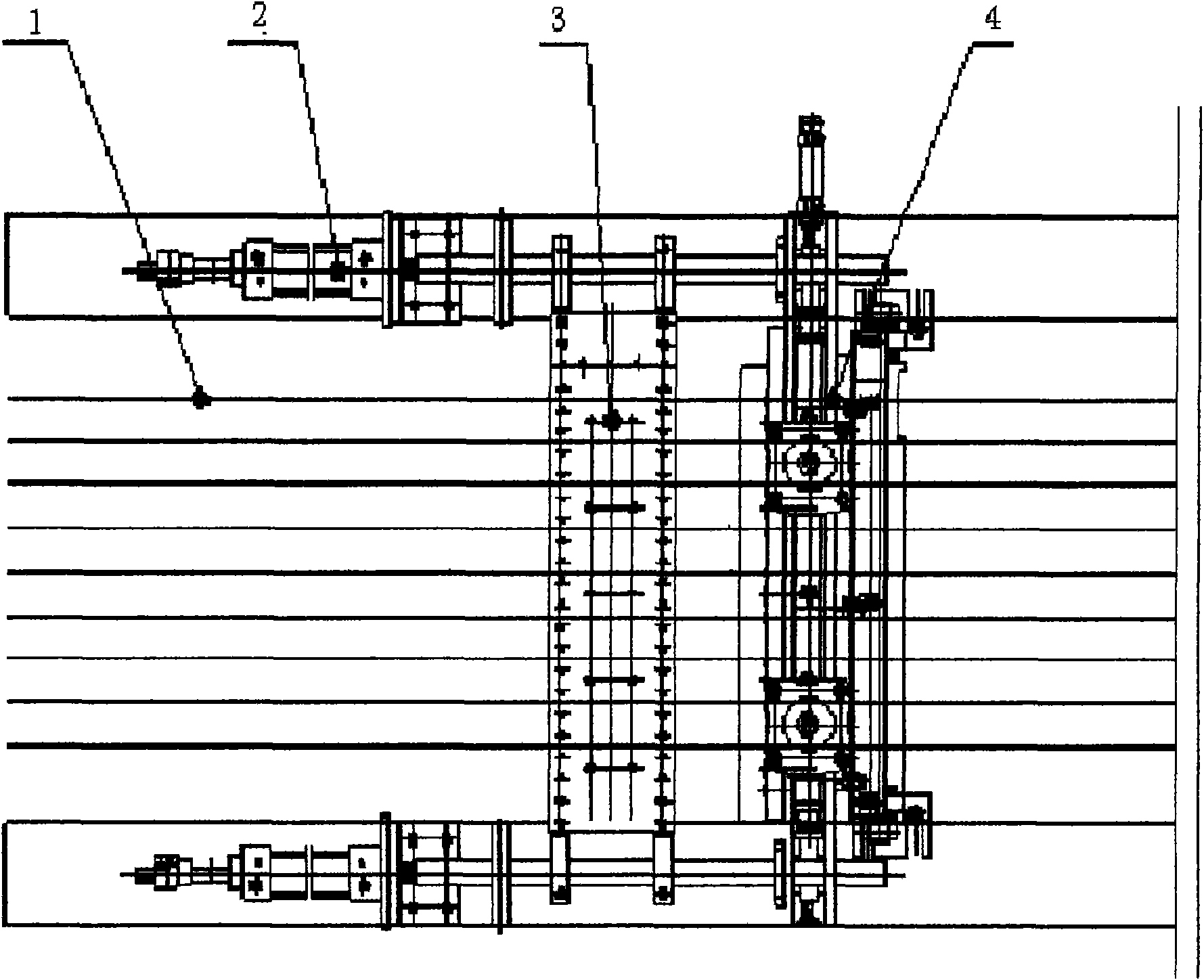

[0019] The specific implementation of the automatic wire feeding mechanism of a pneumatic flat screen welding machine according to the present invention will be described in more detail below in conjunction with the accompanying drawings.

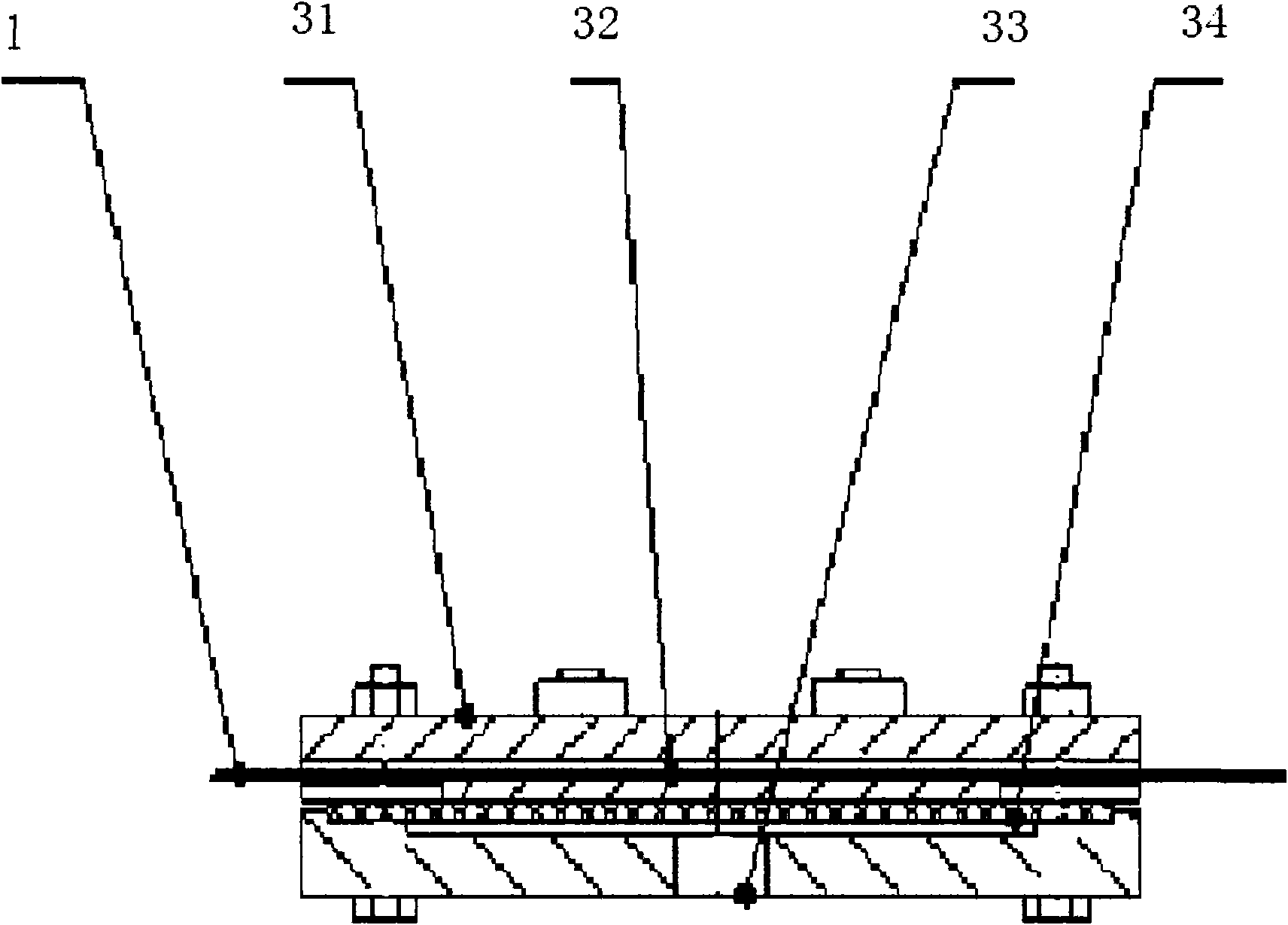

[0020] see figure 1 and figure 2 , an automatic wire feeding mechanism for a pneumatic flat screen welding machine, including a cylinder 2, an airbag clamping mechanism 3, a welding cylinder 4, the airbag clamps a row of iron wires 1, and is driven by the cylinder 2 to feed the iron wire 1 forward, and the airbag clamps Tight mechanism 3 clamps iron wire 1, under the drive of cylinder 2, automatically sends iron wire 1 to welding cylinder 4 welding, and a stroke device can be established on cylinder 2, is used to control the distance of welding cylinder 4 welding. As an embodiment of the present invention, the airbag clamping mechanism 3 includes an airbag 31, an iron plate 32, an air inlet hole 33, and a plastic film 34. The iron plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com