Electric welding machine hoisting cage for building construction

A technology for building construction and electric welding machines, which is applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of poor safety, heavy weight, and difficult transportation, and achieve the effect of protecting safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

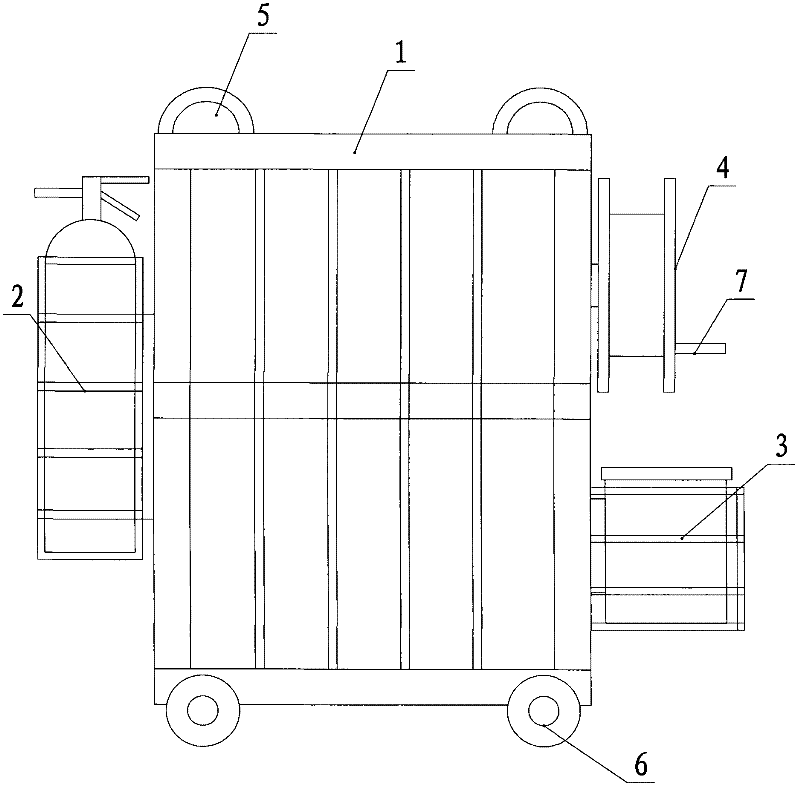

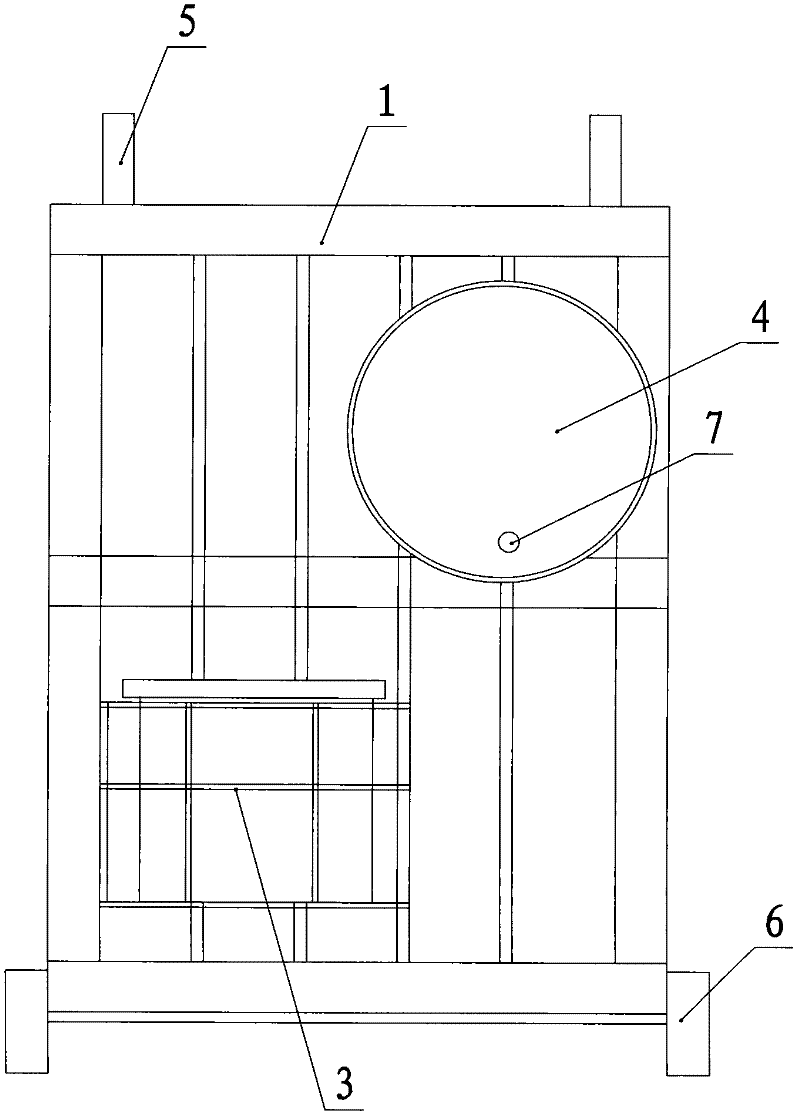

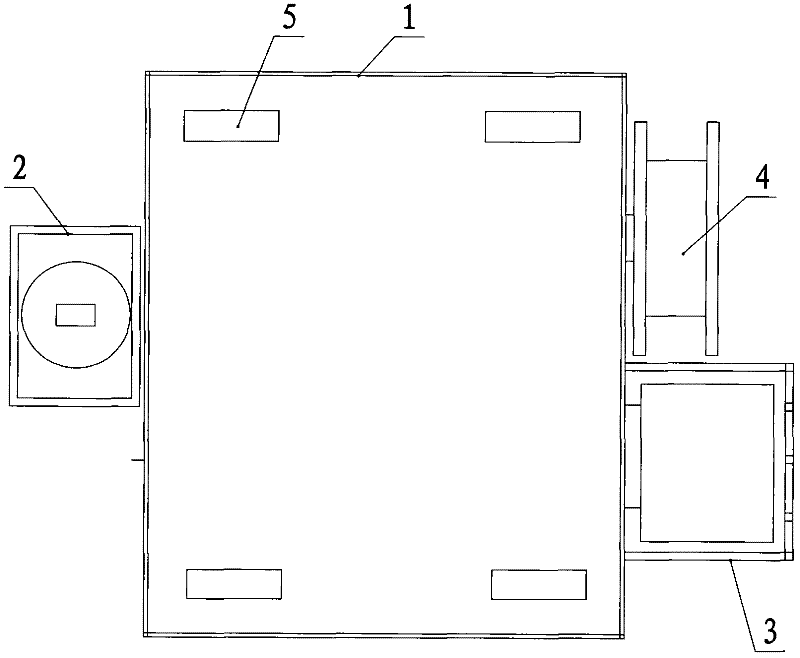

[0020] Example: see Figure 1-Figure 3 In the figure, a welding machine hoisting cage for building construction includes a cuboid cage body, a fire extinguisher cage is provided on one side of the cage body, and a tool box cage and a cable reel are provided on the other side. The lower part of the cage body is provided with casters, and the upper part is provided with suspension rings; the rear part of the cage body is provided with a side-opening door. The cable reel is an I-shaped wheel, and a winding handle is arranged on the I-shaped reel, and the I-shaped wheel is installed on one side of the cage body. The toolbox cage is located at the lower part of the cable reel. The cage body is welded by steel bars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com