Concentrating method for preparing acetylene by partially oxidizing natural gas

An oxidation method and natural gas technology, applied in organic chemistry, absorption purification/separation, etc., can solve problems such as void ratio, specific surface area decrease, increased operating cost, desorption tower blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

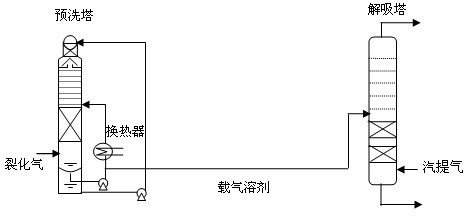

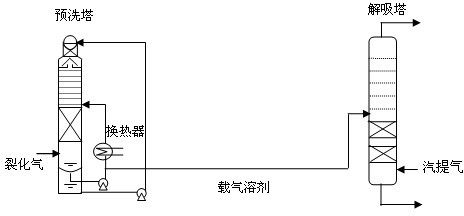

Image

Examples

Embodiment 1

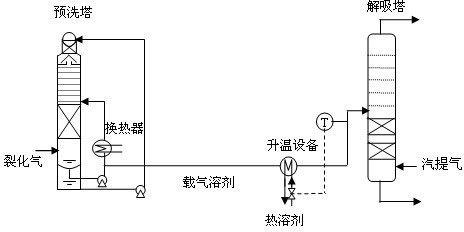

[0021] A method for enriching acetylene by partial oxidation of natural gas, comprising the following steps: the carrier gas solvent saturated with dissolved benzene, naphthalene and higher alkynes from the bottom of the pre-washing tower enters a hot solvent heating device, and the hot solvent heating device The hot solvent in the method is the hot solvent coming out of the vacuum tower in the enrichment process of acetylene produced by the partial oxidation of natural gas; the carrier gas solvent is heated through the temperature raising device, and the carrier gas solvent pipeline between the temperature raising device and the desorption tower Set the temperature probe, the carrier gas solvent is heated to 52°C and then enters the middle of the desorption tower, passes through two layers of packing and is in countercurrent contact with the stripping gas from the bottom of the tower, such as figure 2 shown.

Embodiment 2

[0023] A method for enriching acetylene by partial oxidation of natural gas, comprising the following steps: the carrier gas solvent dissolving benzene, naphthalene and higher alkynes from the bottom of the pre-washing tower enters a hot solvent heating device, and the hot solvent heating device The hot solvent is the hot solvent that comes out of the vacuum tower in the enrichment process of acetylene produced by partial oxidation of natural gas; the temperature of the carrier gas solvent is raised through the heating device, and the carrier gas solvent enters the middle of the desorption tower after the temperature is raised to 50 ° C, and passes through two layers of packing. Countercurrent contact with the stripping gas from the bottom of the column.

Embodiment 3

[0025] A method for enriching acetylene produced by partial oxidation of natural gas, comprising the following steps: the carrier gas solvent saturated with dissolved benzene, naphthalene and higher alkynes from the bottom of the pre-washing tower enters an electric heating heating device, and the carrier gas is heated by the heating device. The gas solvent is heated up, and a temperature probe is installed on the carrier gas solvent pipeline between the temperature raising device and the desorption tower. After the carrier gas solvent is heated to 53°C, it enters the middle of the desorption tower, passes through two layers of packing and is stripped from the bottom of the tower. Gas countercurrent contact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com