Anti-scaling mesh belt vibrated fluidized bed

A vibrating fluidized bed, anti-scaling technology, applied in hearth furnaces, drying solid materials, dryers, etc., can solve the problems of raw material waste, product color and quality impact, fluidized bed scaling, etc. Increase drying efficiency, improve quality, and solve the effect of scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

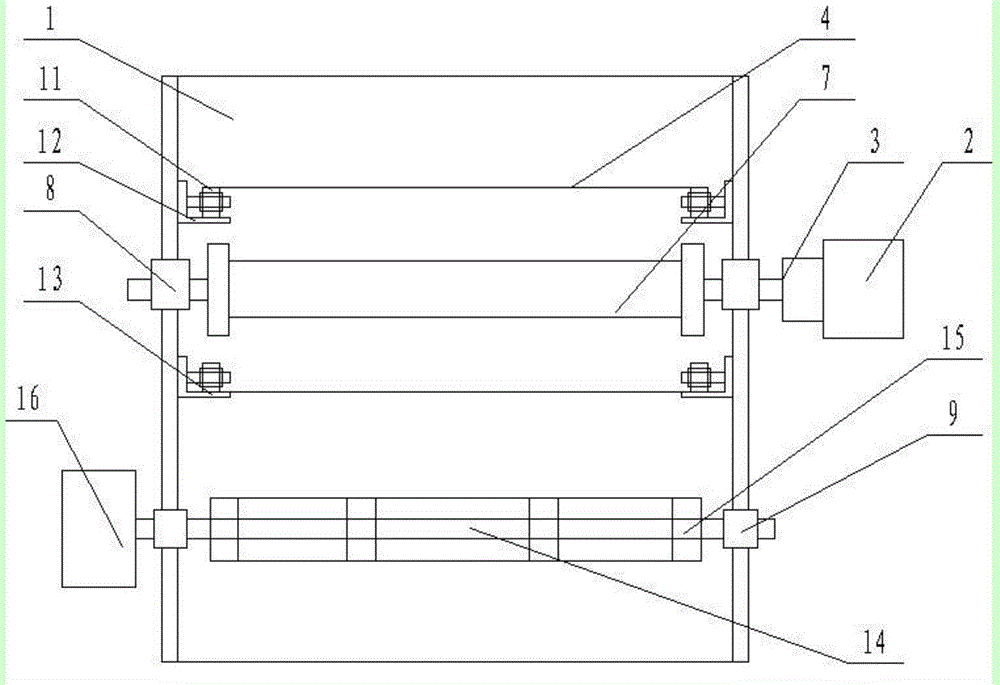

[0017] The present invention will be further described in detail below in conjunction with specific embodiments and drawings.

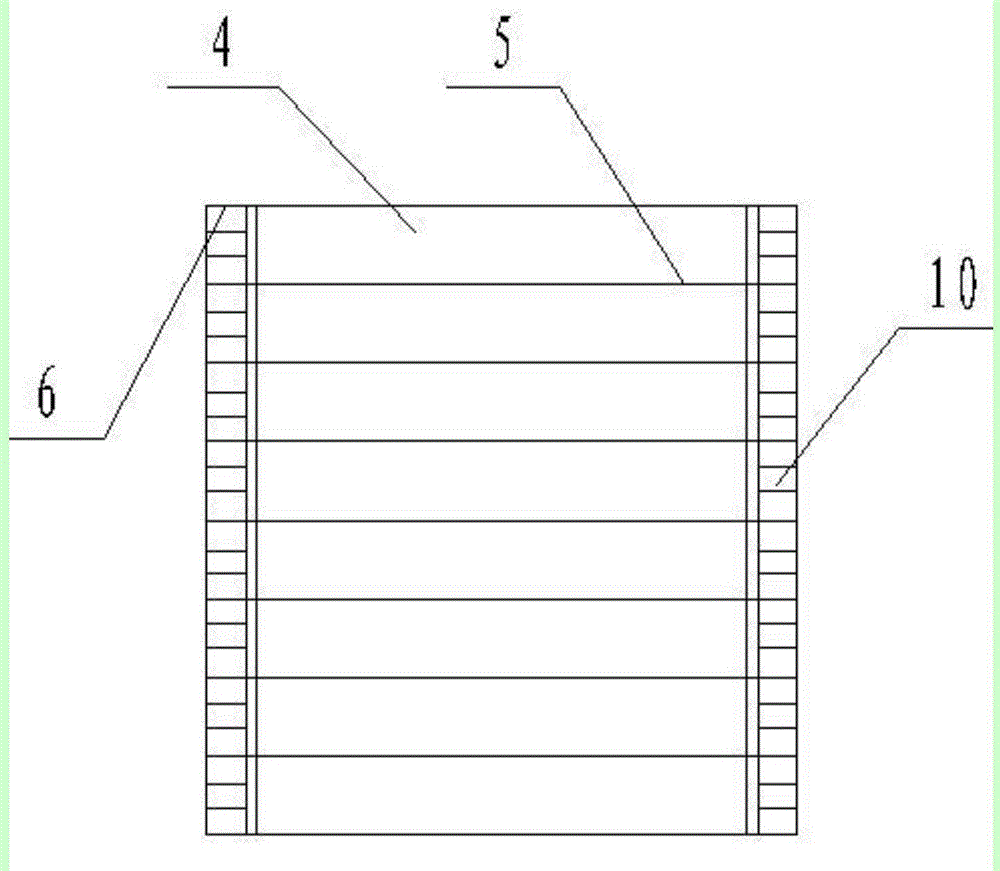

[0018] An anti-scaling mesh belt vibrating fluidized bed such as figure 1 with figure 2 As shown, the fluidized bed box 1 is included. The fluidized bed box 1 includes a vibrating device and a mesh belt system; the mesh belt system is arranged on the upper part of the vibrating device, and the mesh belt system includes a power device and a conveyor belt 4, The mesh belt brace 5, the mesh belt chain 6 and the rotating bearing 7; the rotating bearing 7 is fixed on the side frame of the fluidized bed box 1 through the second shaft seat 9. The mesh belt chain 6 is symmetrically arranged on the two sides of the conveyor belt 4 On the side, the mesh belt chain 6 includes a chain hole 10 and a sprocket 11. The sprocket 11 is symmetrically arranged at both ends of the rotating bearing 7; the conveyor belt 4 includes a net belt and a lower mesh belt, and the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com