Supercritical CO2 foaming system used for microporous polymer preparation

A microporous polymer and foaming system technology, which is applied in the field of supercritical CO2 foaming system, can solve the problems of large cell diameter, low diffusion rate, and large interfacial tension of foaming materials, so as to improve foaming performance and improve Diffusion rate, effect of shortening the time period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the invention are not limited thereto.

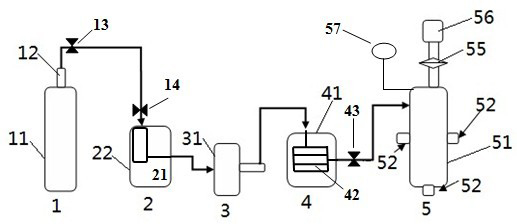

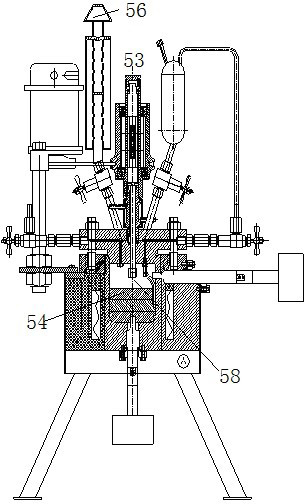

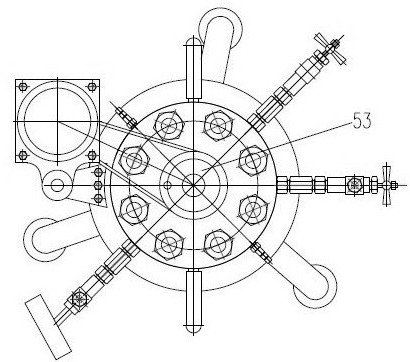

[0021] Such as figure 1 As shown, a supercritical CO for the preparation of microporous polymers 2 Foaming system, including gas supply group 1, gas-liquid separation group 2, pressurization group 3, preheating group 4 and supercritical CO 2 High pressure reactor 5. The gas supply group 1, gas-liquid separation group 2, pressurization group 3, preheating group 4 and supercritical CO 2 The high-pressure reactor 5 is connected by a high-pressure pipeline, and an outlet valve and an inlet valve are correspondingly provided at the entrance and exit. The supercritical CO 2 The autoclave 5 includes a autoclave 51, and the outer surface of the autoclave 51 is provided with a multi-frequency ultrasonic generator 52. Further, a detachable mechanical stirring paddle 53 is provided inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com