Heald separation device for spinner

A textile machine and heald frame technology, which is applied in the field of heald frame slicing devices for textile machines, can solve the problems of reducing production efficiency, consuming physical strength, and heavy female workers, and achieves the effects of reducing labor intensity, increasing production efficiency, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

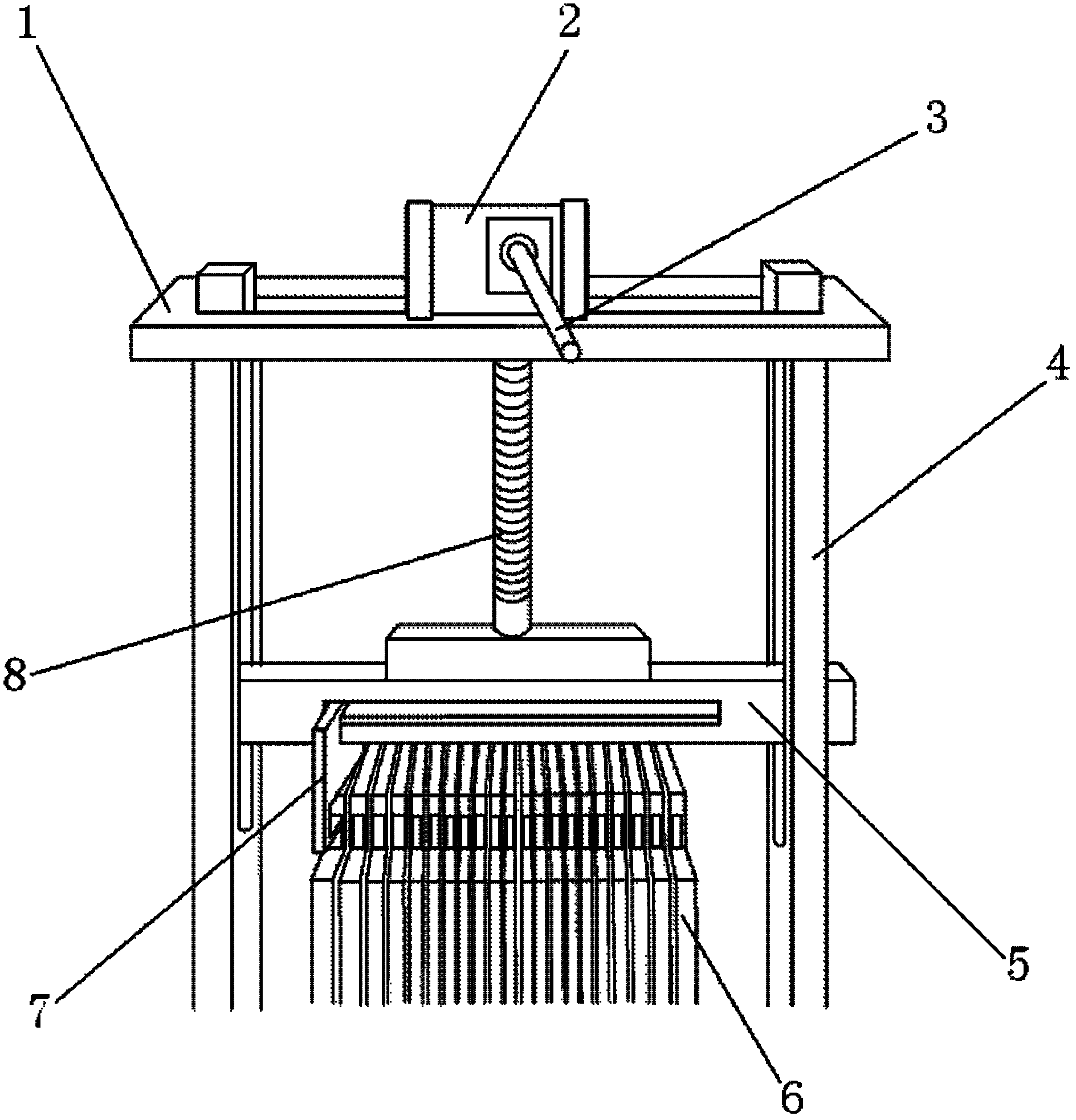

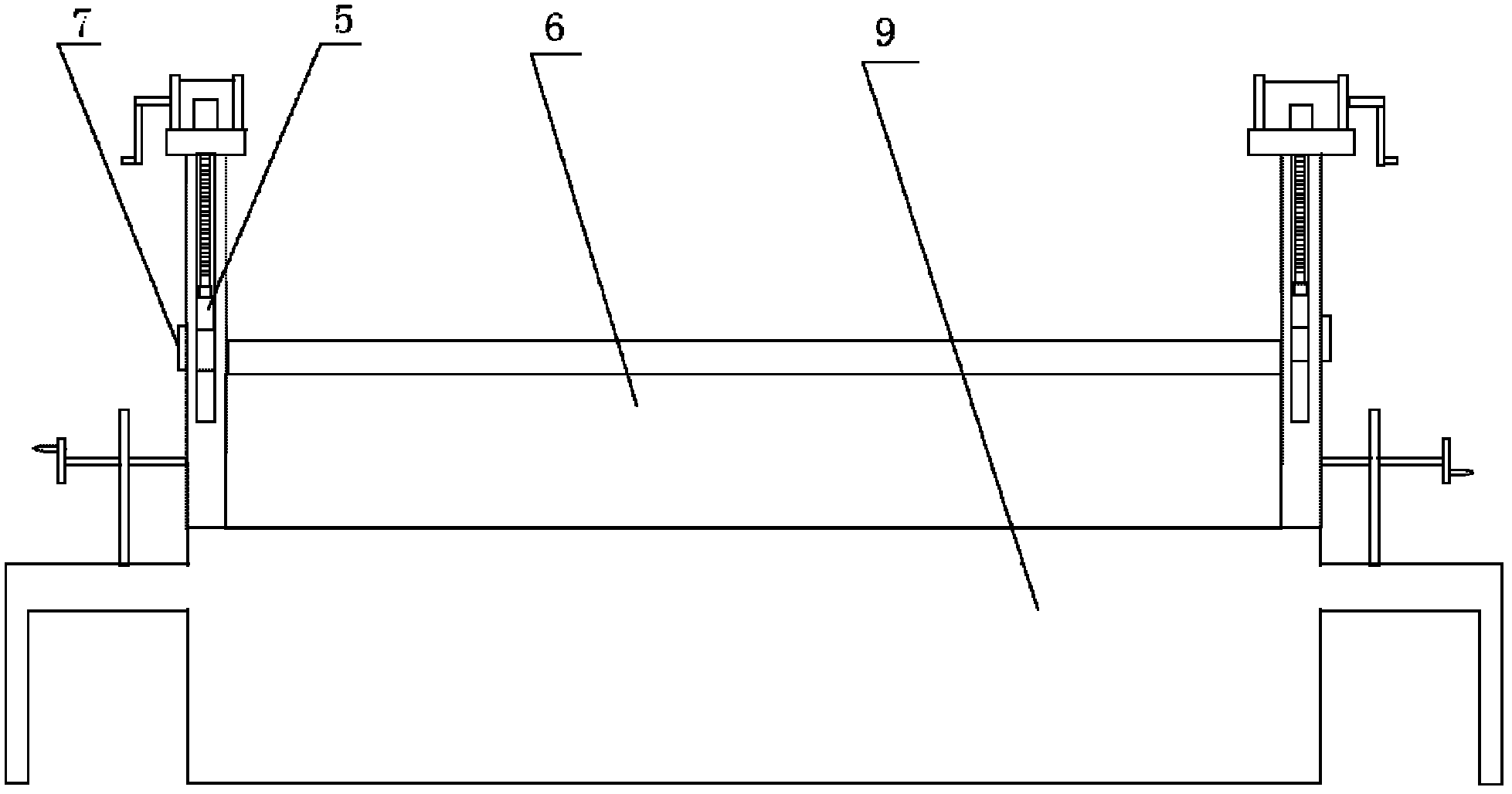

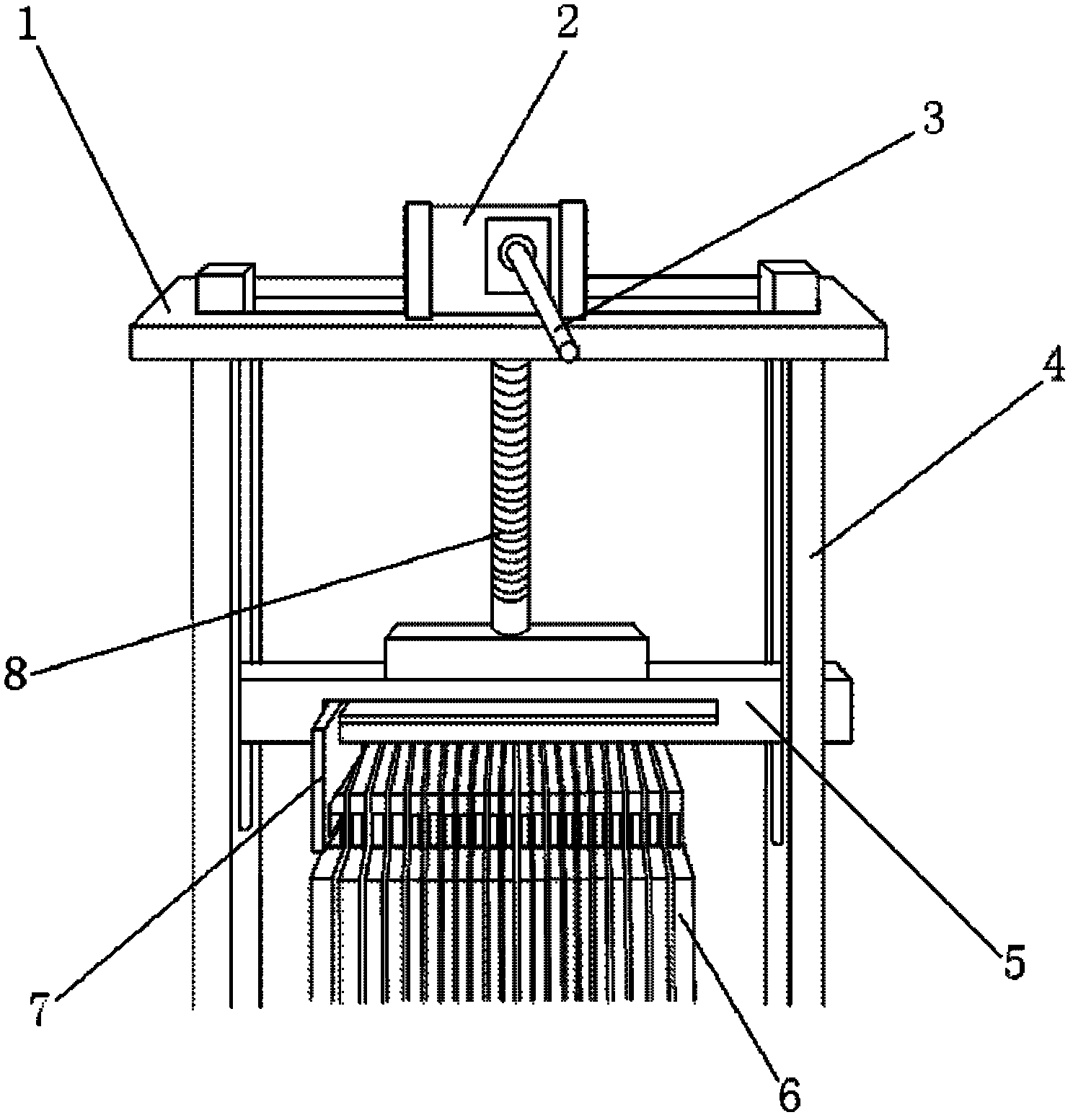

[0017] like Figure 1 ~ Figure 2 As shown, a heald frame splitting device for a textile machine includes a support block 1, a regulator 2, a regulator crank 3, a heald frame 4, a heald frame adjusting block 5, a heald frame 6, and a heald frame split buckle 7, Stud 8 and frame 9, there is a horizontal groove in the middle position of described support block 1, and heald frame 4 is installed in the left and right sides of the horizontal groove of support block 1, and heald frame 4 is installed on the frame 9; 2 is installed in the middle of the horizontal groove of the support block 1, and the output end of the bottom of the regulator 2 is connected to the heald frame adjustment block 5, there are guide grooves on the inner sides of the two heald frames 4, and the two ends of the heald frame adjustment block 5 are respectively installed on the left and right heald frames In the guide groove of 4, the heald frame adjusting block 5 sides have transverse grooves.

[0018] The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com