Stepless cross pitch sectional continuous backfilling mining method of gently-inclined medium-thickness ore body

A technology of gently inclined medium-thickness and filling mining method, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of large exposed area of empty area, complex mining process, and low degree of roof connection, and achieve simple process, mining The effect of high efficiency and small environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

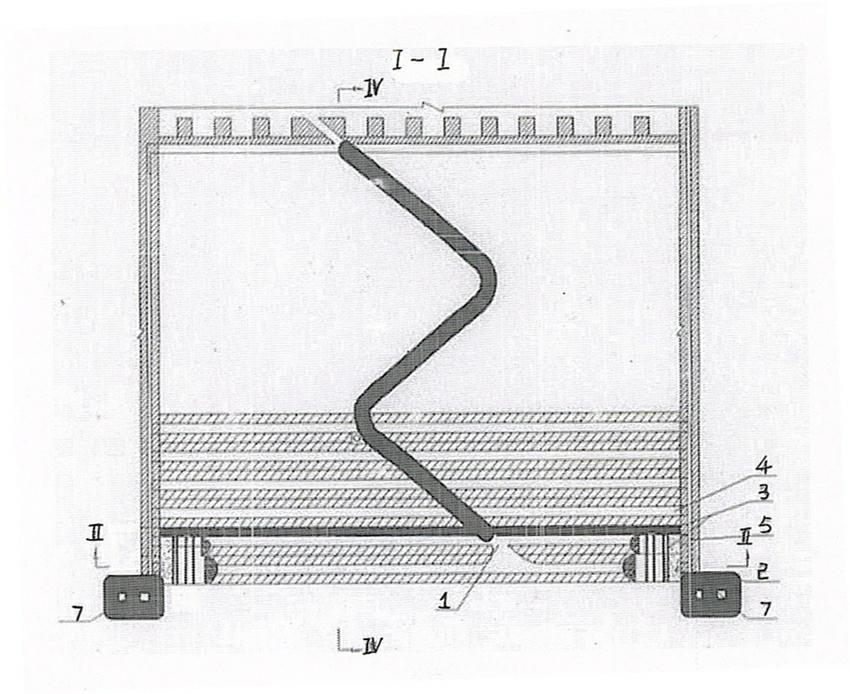

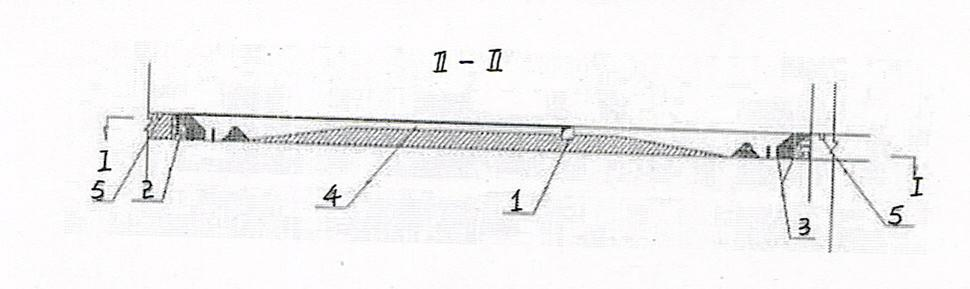

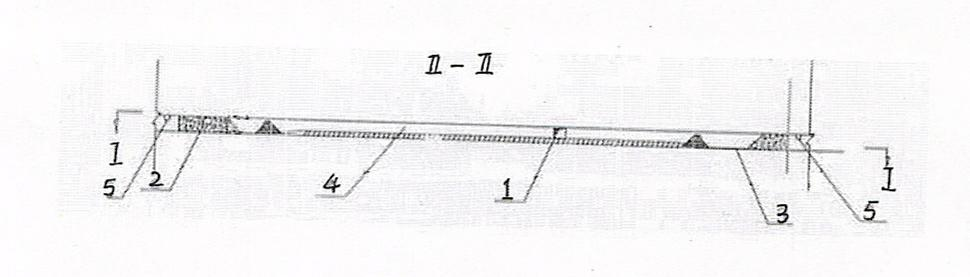

[0023] Mining example of the No. 5 shaft of the Mill Mine without stages along the strike and then filling mining method:

[0024] The ore body mined by Wengfu Phosphate Mineral Mill is a marine sedimentary phosphate deposit, with a thickness of 4-12 meters and an inclination angle of 6-14°. The immediate roof is the first member of the Dengying Formation (Zb 2-1 ) dolomite, siliceous agglomerate dolomite and siliceous rock, with a thickness of 16-20 meters, and the direct floor is generally the third member of the Doushantuo Formation (Zb 1-3 ) White siliceous rock containing colloidal phosphate lumps, the roof is a relatively stable rock formation, and the ore is not flammable.

[0025] 1. Development: adopt the development method of the main adit-slope, and arrange the turn-back trackless ramp along the ore body to reach each layered entry; arrange two return air inclined shafts at the end of the ore body to communicate with each layered entry ; Arrange a substation cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com