Power conversion device

A technology of power conversion and sliding surface, which is applied to machines/engines, liquid variable capacity machinery, pumps with flexible working elements, etc., can solve the problems of low power conversion, high requirements on machining precision of parts, and high manufacturing cost of large equipment. Achieve the effect of simple manufacturing process, high power conversion ratio and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

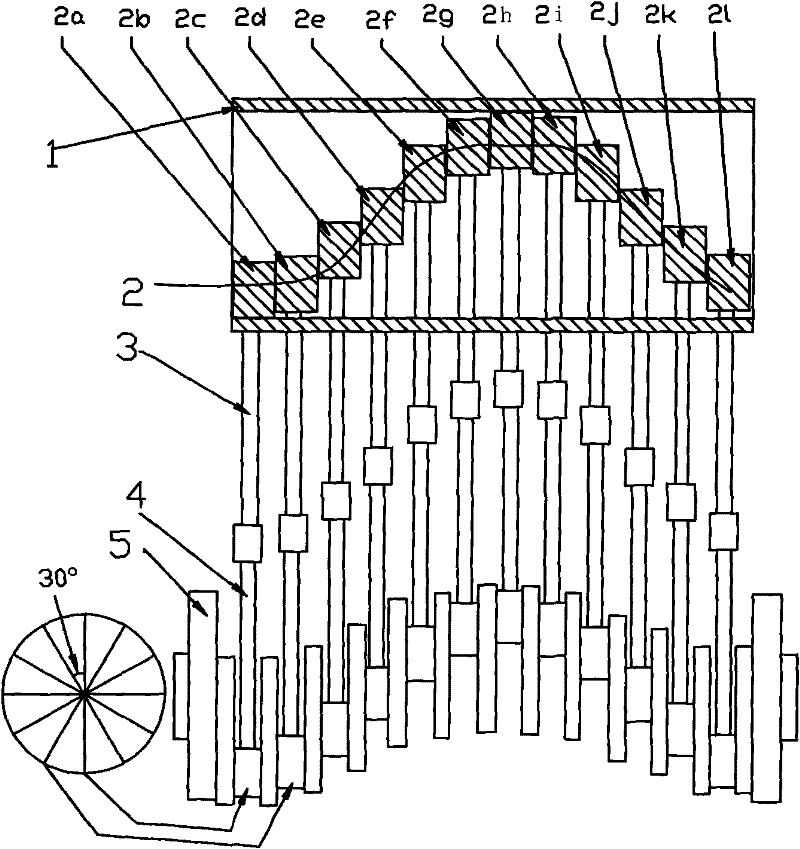

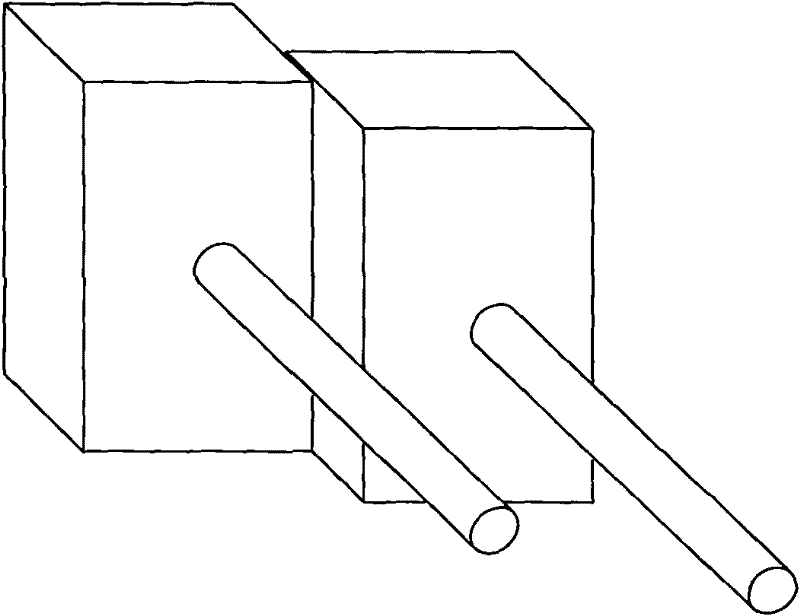

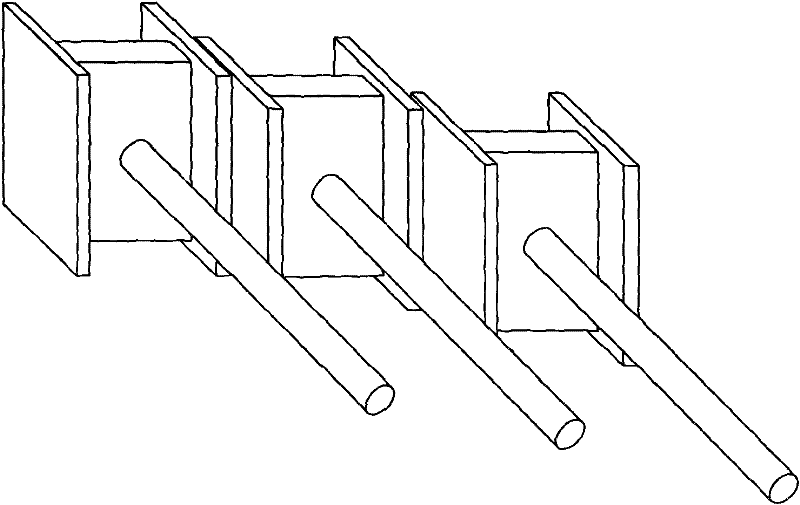

[0023] Refer to attached figure 1 , the power conversion device of the present invention includes a shell 1, a piston group 2, and a crank mechanism, wherein: the shell 1 is a rectangular cylindrical structure with two ends open, the two opposite inner walls of the shell are working surfaces, and the other two opposite The inner wall is a sliding surface; the piston group 2 is composed of twelve independent pistons from 2a to 21, each piston has two working surfaces, two sliding surfaces and two combination surfaces, and the two working surfaces of the pistons are respectively connected to the casing The two working surfaces are opposite, the two sliding surfaces are in contact with the two sliding surfaces of the housing, the pistons are arranged side by side with the combined surfaces to form a piston group, and the piston groups are arranged in the housing along the axial direction of the housing; each piston An independent piston rod 3 of equal length is provided, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com