Backlight module and LED (light emitting diode) module

A technology of light-emitting diodes and modules, applied in the fields of light-emitting diode modules and backlight modules, can solve the problems of large number of light-emitting diodes, high power, aging of lighting sources, etc., and achieve the effect of good heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

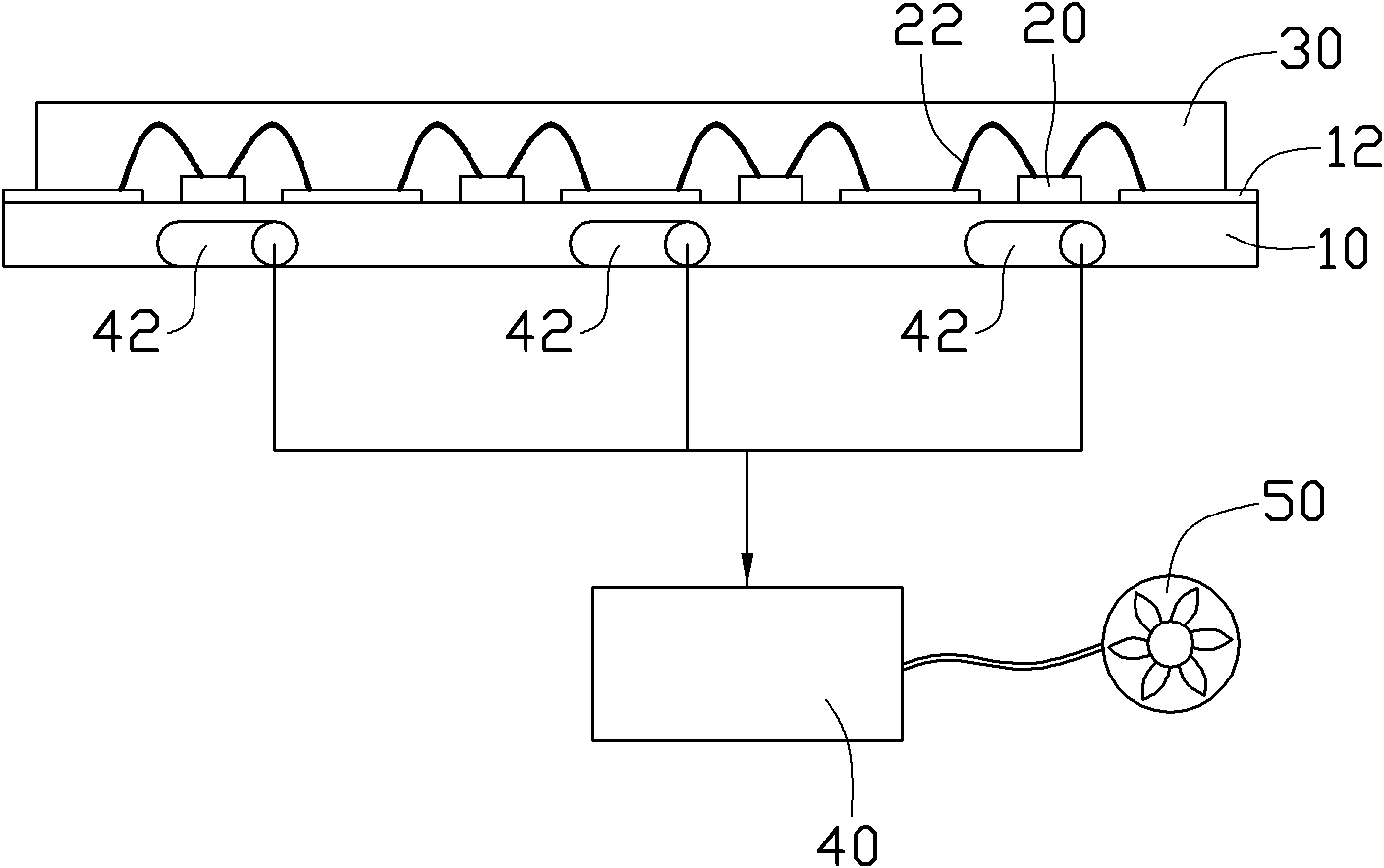

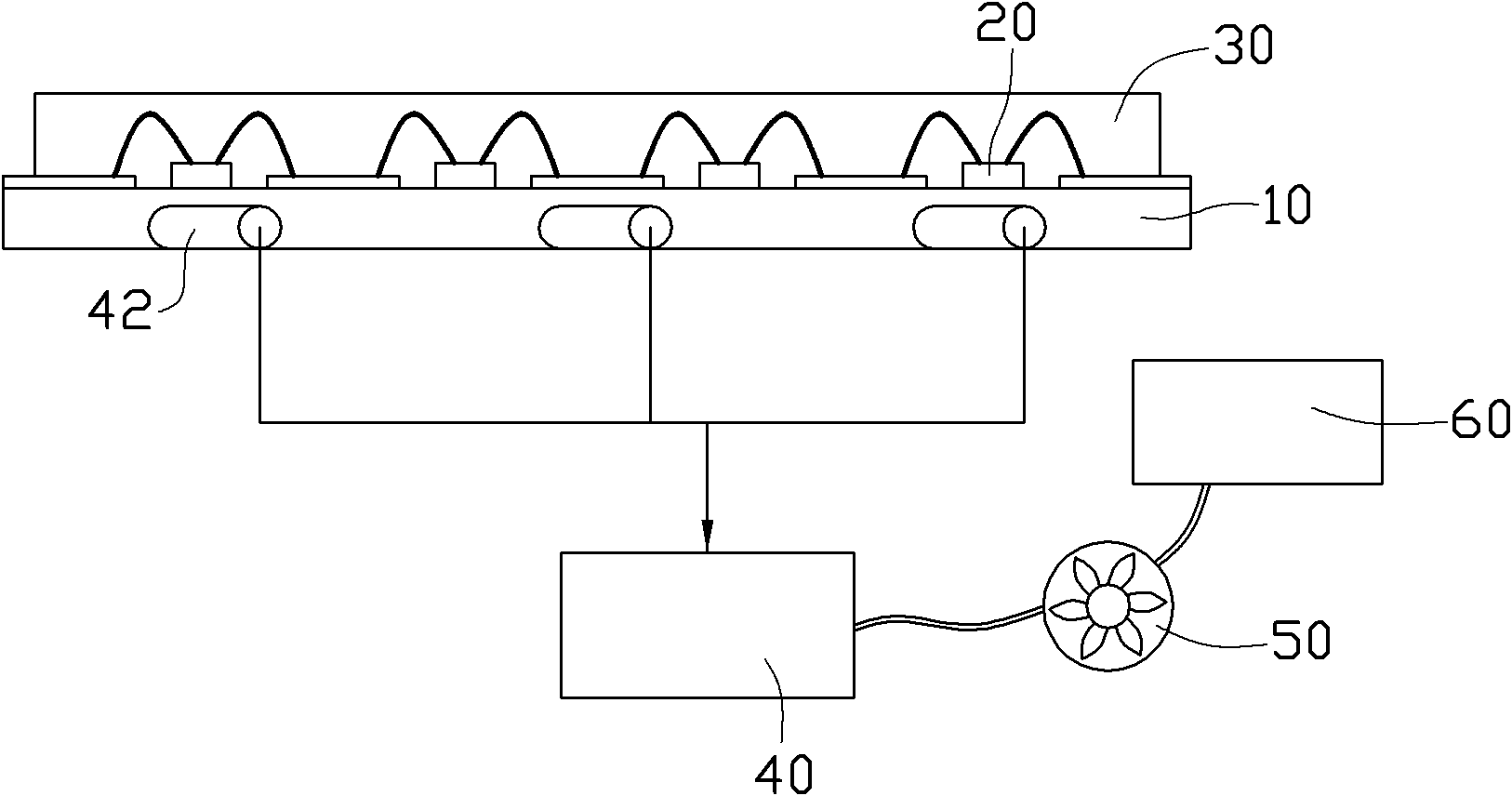

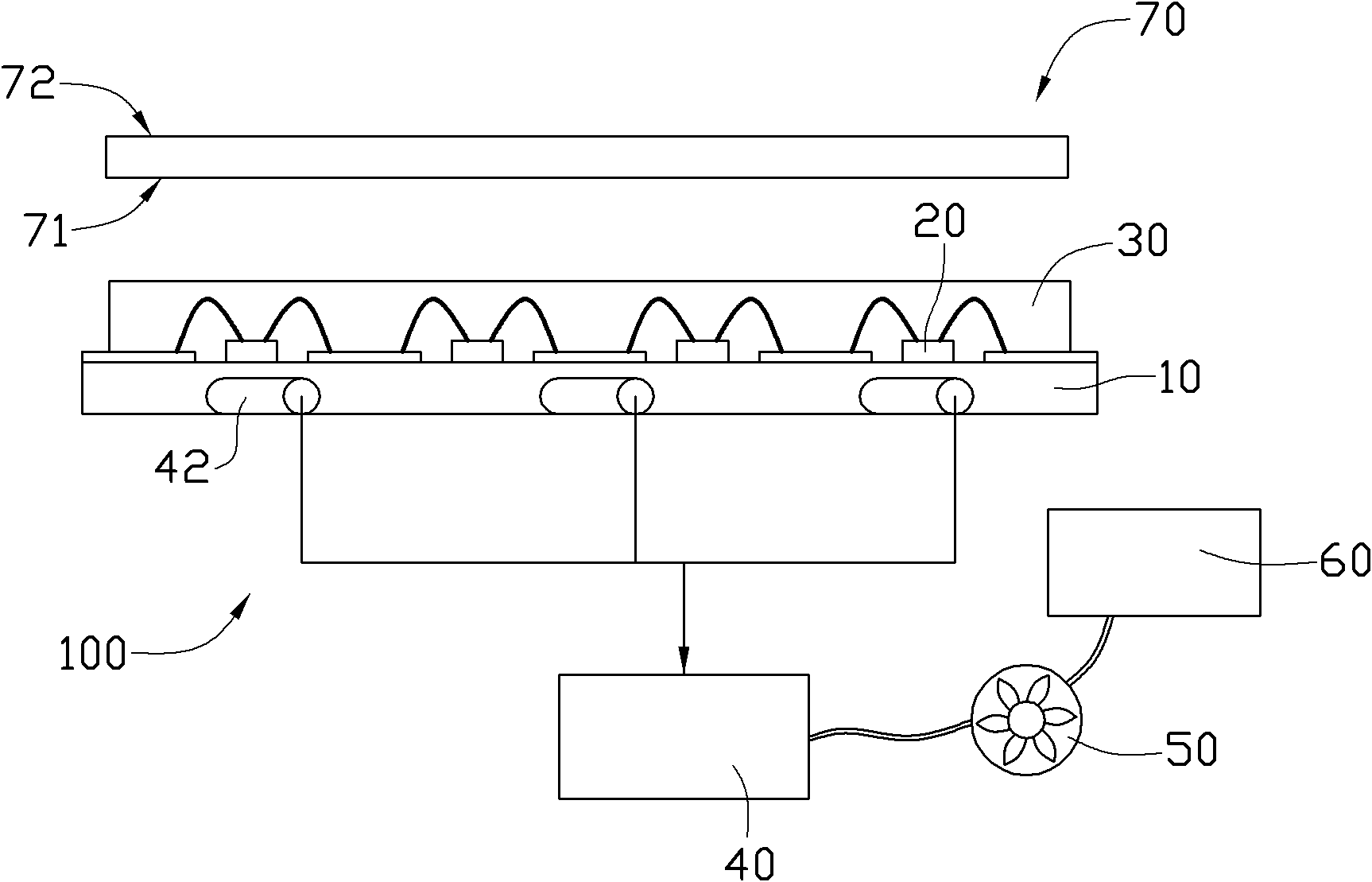

[0026] Please refer to figure 1 The light emitting diode module provided by an embodiment of the present invention comprises a heat sink 10, a plurality of light emitting diode chips 20 arranged on the heat sink 10, a phosphor layer 30 arranged on the heat sink 10 and covering the light emitting diode chips 20, and heat dissipation The thermoelectric conversion device 40 connected to the board 10 and the cooling fan 50 connected to the thermoelectric conversion device 40 .

[0027] The heat dissipation plate 10 can be made of materials with good heat dissipation performance, such as ceramics. A circuit layer 12 is also provided on the heat dissipation plate 10 , and the circuit layer 12 may be formed on the heat dissipation plate 10 by using techniques such as lithographic etching.

[0028] The LED chip 20 may be an InGaN series LED chip. Preferably, the light-emitting diode chip 20 is directly packaged on a circuit board (Chip On Board, COB), which can avoid the additional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com