High-temperature radiation temperature enhancement device of quartz lamp used for guided missile thermal test

A high-temperature radiation and enhancement device technology, which is applied in weapon accessories, weapon testing, offensive equipment, etc., can solve the problems of tungsten filament burning, quartz heater vacuum seal leakage, etc., and achieve the effect of increasing the thermal radiation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

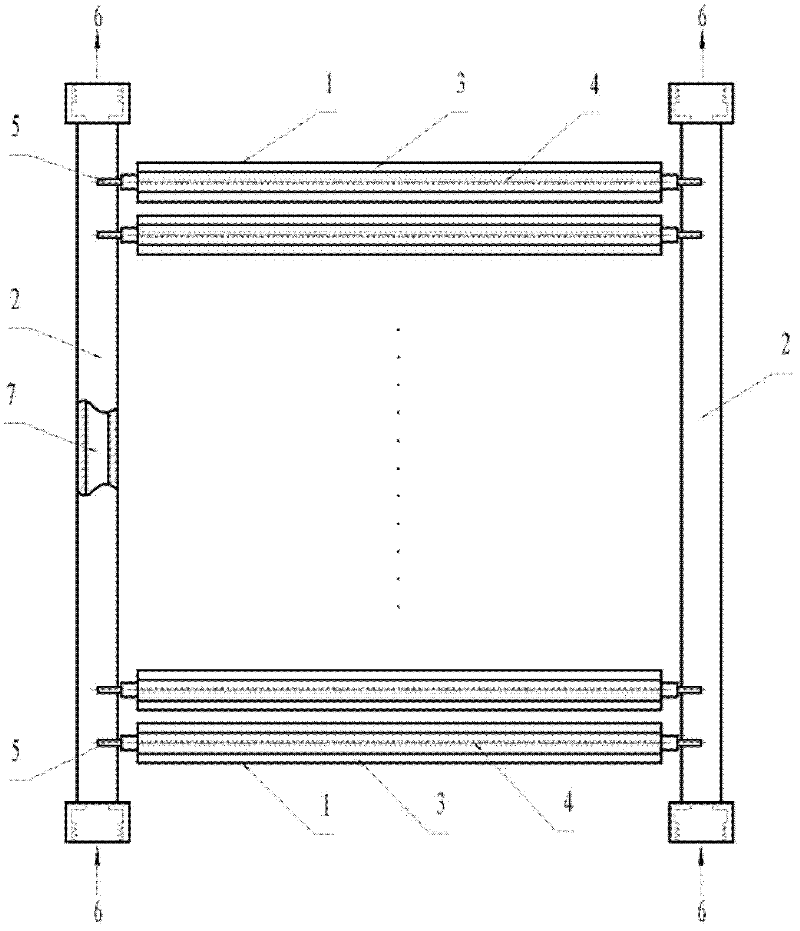

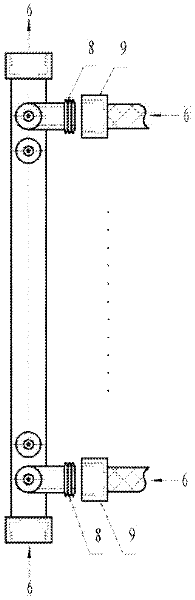

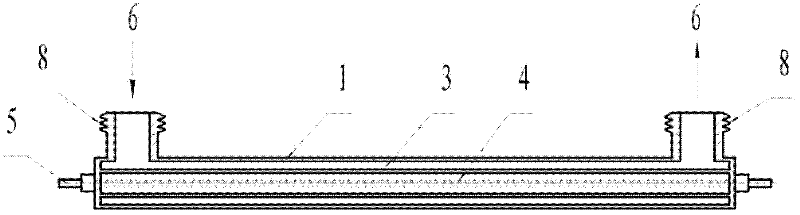

[0022] Such as figure 1 , 2 , 3, the present invention consists of interlayer water-cooled quartz lamp heater 1, water-cooled copper electrode holder 2, lamp wall water flow channel 3, tungsten heating wire 4, quartz lamp electrode 5, cooling water 6, through water cooling channel 7, water inlet Or the water outlet 8 and the metal connecting pipe 9 are formed. The interlayer water-cooled quartz lamp heater 1 is fixed on the water-cooled copper electrode holder 2 to form a horizontally placed densely arranged planar heating array. The tungsten heating wire 4 is on the central axis inside the interlayer water-cooled quartz lamp heater 1 and is connected to the quartz lamp electrodes. 5, one end of the water inlet or water outlet 8 is connected to the water flow channel 3 of the lamp wall, and the other end of the water inlet or water outlet 8 is connected with the metal connecting pipe 9. The tungsten heating wire 4 radiates infrared light after being powered on, and the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com