Self-calibration method and system for magnetostriction liquid level sensor

A magnetostrictive liquid level and sensor technology, which is used in buoy liquid level indicators, test/calibration devices, instruments, etc., can solve the problems of large differences in the measurement accuracy of magnetostrictive liquid level sensors, and achieves simple and easy structure. Installation and maintenance, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

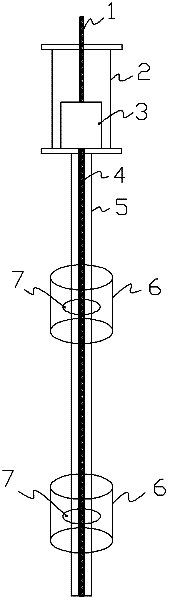

[0026] combine figure 1 , The magnetostrictive liquid level sensor is mainly composed of a single-chip microcomputer, a signal line 1, a sensor head 2, a pulse processing module 3, a waveguide wire 4, a waveguide 5, a liquid level float 6, and a magnet 7 in the float.

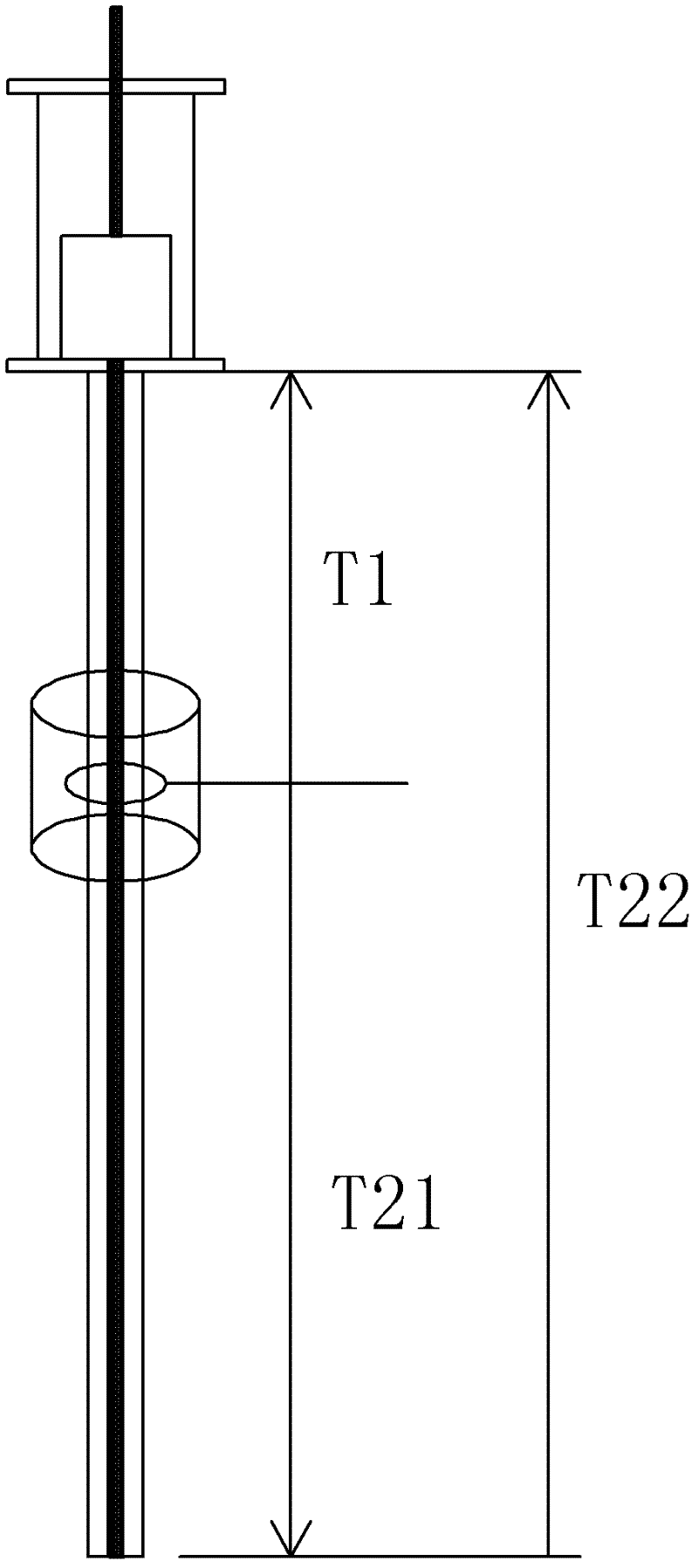

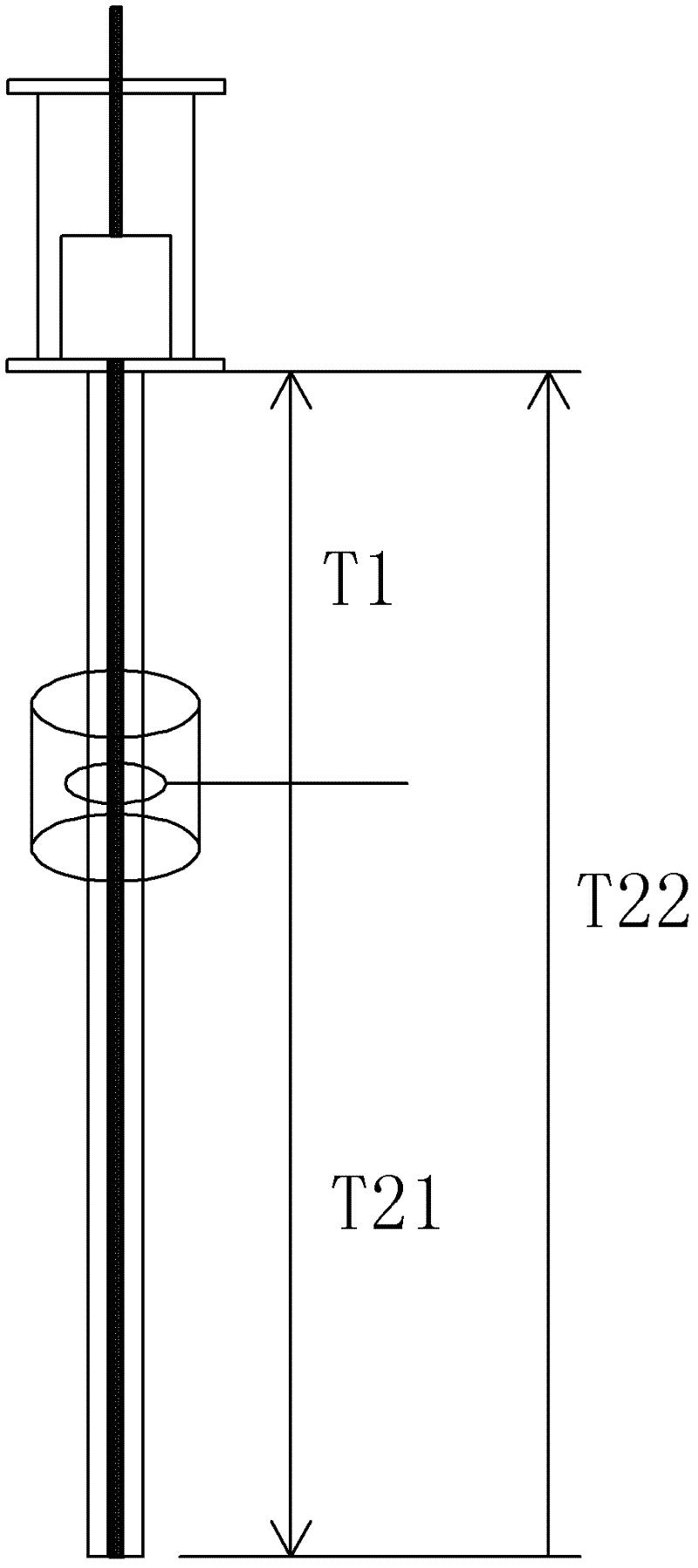

[0027] combine figure 2 , a self-calibration method of a magnetostrictive liquid level sensor, comprising the steps of:

[0028] A current pulse is generated by the pulse processing module of the magnetostrictive liquid level sensor. When the current pulse propagates in the waveguide wire and meets the magnet in the float, a torsional wave will be generated. The time T1 of the processing module, and the measurement of the time T2 when the above-mentioned torsional wave propagates down to the end of the waveguide wire and is reflected and propagates upwards to the pulse processing module.

[0029] Using the probe rod length H (constant) of the magnetostrictive liquid level sensor and the above-mentioned times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com