Micro photometer

A photometer and micro-quantity technology, applied in the field of measurement, can solve problems affecting instrument performance, manual operation errors, measurement errors, etc., and achieve the effect of high-throughput screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

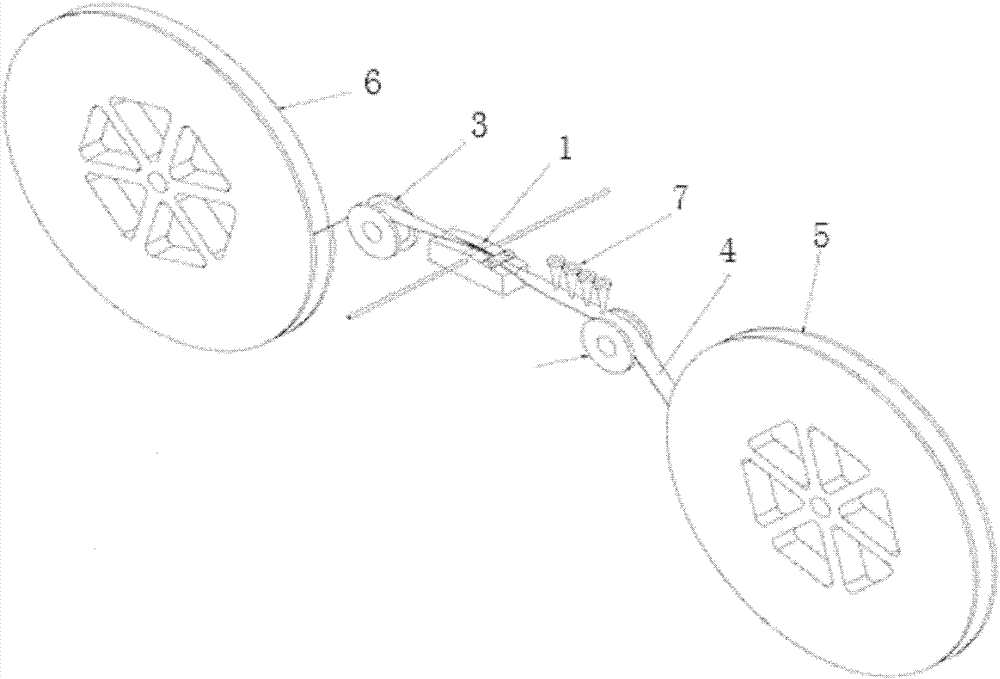

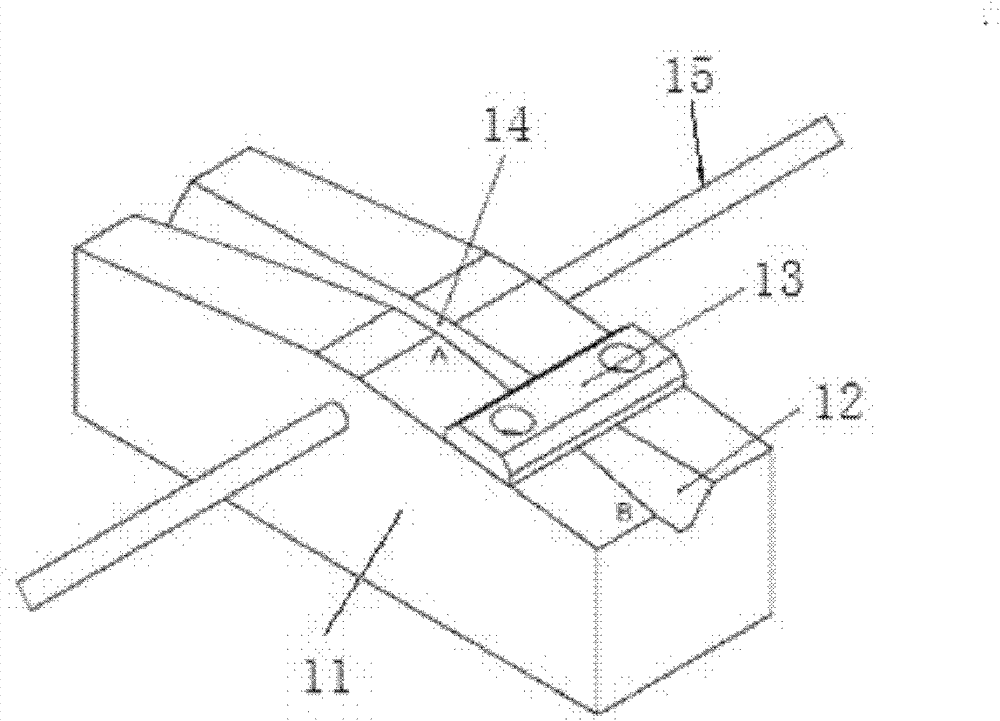

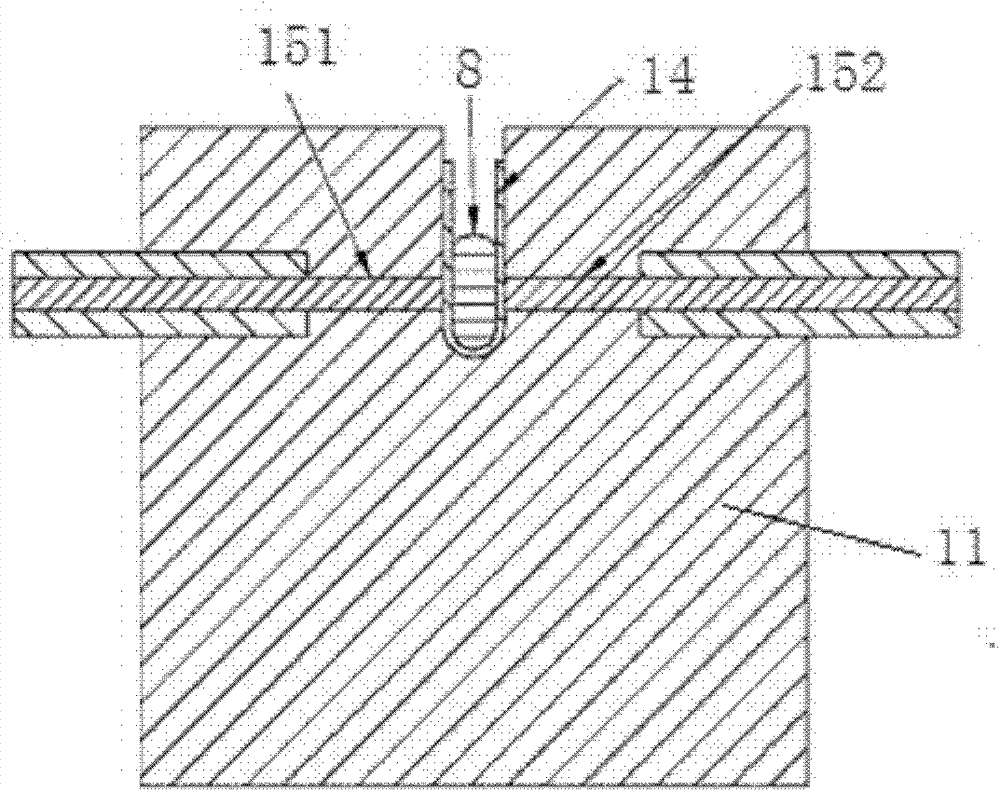

[0024] see figure 1 A microphotometer provided by an embodiment of the present invention includes a microphotometer cell 1 , a front support 2 , a rear support 3 , a plastic film belt 4 , a front roll 5 , a rear roll 6 and a spotting mechanism 7 . The plastic film belt 4 wound on the front roll 5 is connected with the back roll 6 through the front support 2 , the sample point mechanism 7 , the microphotometric cell 1 , and the back support 3 in sequence. The plastic film belt 4 should be optically transparent, and have a certain degree of elasticity and can be bent and deformed. Some types of plastic film belts made by extrusion molding can meet this requirement. The front support 2 and the rear support 3 are rollers or struts. The sample spotting mechanism 7 can be a manual pipette gun, a multi-channel pipette gun, a pipette on a mechanical arm, etc., and is used for dripping liquid droplets into the plastic film tape. For example, the sample pointing mechanism 7 may be a 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com