Multi-channel high-throughput catalyst evaluation device and evaluation method

A catalyst and high-throughput technology, applied in the direction of using catalysis for chemical analysis, etc., can solve the problems of heavy catalyst evaluation workload, unavoidable relative error, and unguaranteed test conditions, so as to improve evaluation efficiency and credibility , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

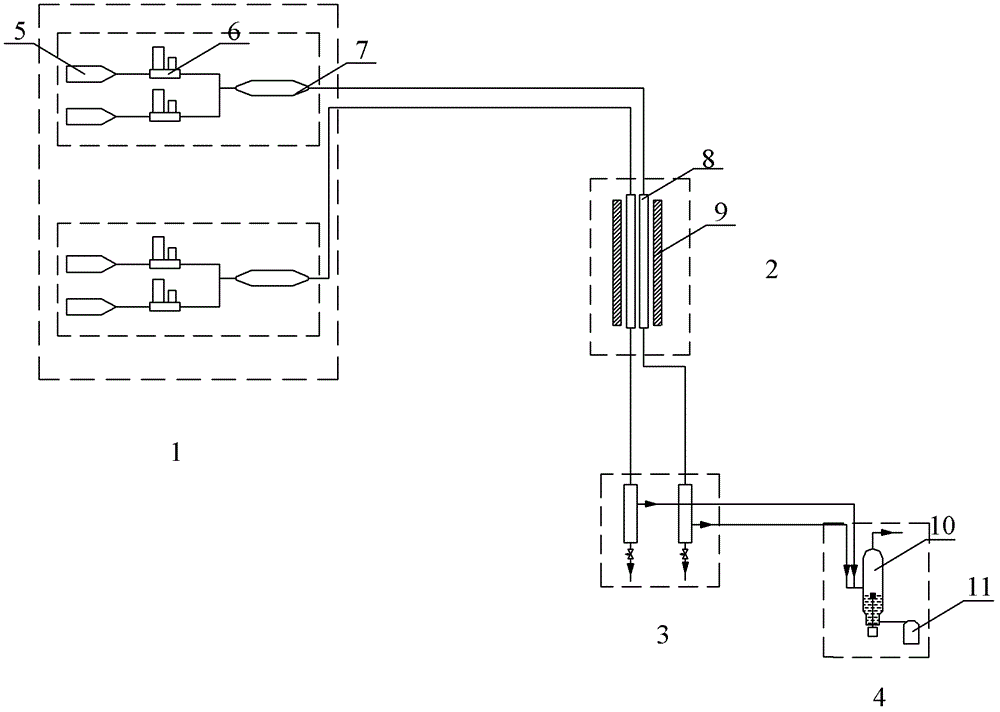

[0037] A multi-channel high-throughput catalyst evaluation device, including a feed system 1, a reaction system 2, a sampling analysis system 3, and a product collection system 4 connected in sequence; the feed system 1 is two, including gas phase feed channels 5. Mass flow controller 6 and mixing unit 7; reaction system 2 is composed of multi-channel reactor 8 and external heating unit 9 of multi-channel reactor 8, multi-channel reactor 8 has two branch reactors, feed system 1 One-to-one correspondence with each branch reactor of the multi-channel reactor 8 ; the product collection system 4 includes a high-pressure separator 10 and a product storage unit 11 .

[0038] Put the catalyst to be evaluated into each branch reactor; let the reaction samples A and B pass through the A mass flow controller and the B mass flow controller respectively, and enter the mixing unit at the same time to mix the two gases evenly, and then enter the multi-channel reactor After the reaction is c...

Embodiment 2

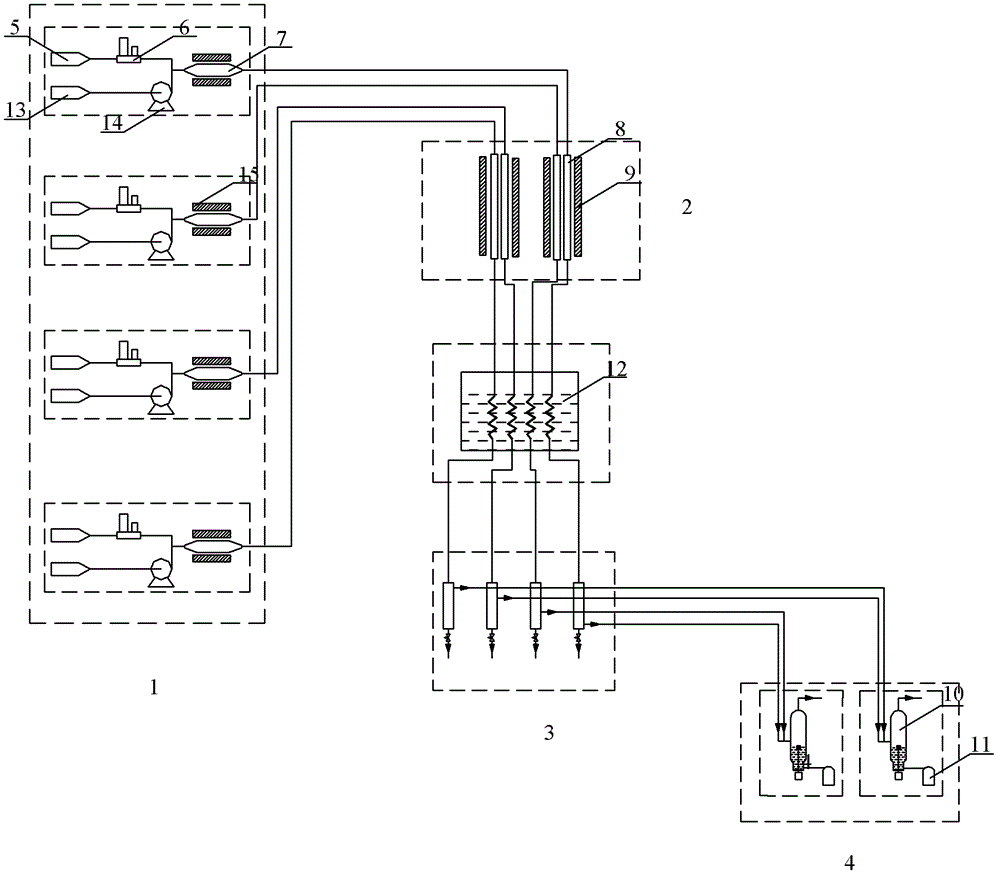

[0040] A multi-channel high-throughput catalyst evaluation device, comprising a feed system 1, a reaction system 2, a heat exchanger 12, a sampling analysis system 3, and a product collection system 4 connected in sequence; there are four feed systems 1, respectively Comprising a gas phase feed channel 5 and a mass flow controller 6, a liquid phase feed channel 13, a metering pump 14 and a mixing unit 7, the outside of the mixing unit 7 is provided with a heater 15; there are two reaction systems 2, each composed of a multi-channel reaction 8 and the external heating unit 9 of the multi-channel reactor, the multi-channel heater 8 has two branch reactors, and the feed system 1 corresponds to each branch reactor of the multi-channel reactor 8; the product collection system 4 is Two, including high pressure separator 10 and product storage unit 11 .

[0041] Put the catalyst to be evaluated into each branch reactor; let the reaction samples A and B pass through the A mass flow co...

Embodiment 3

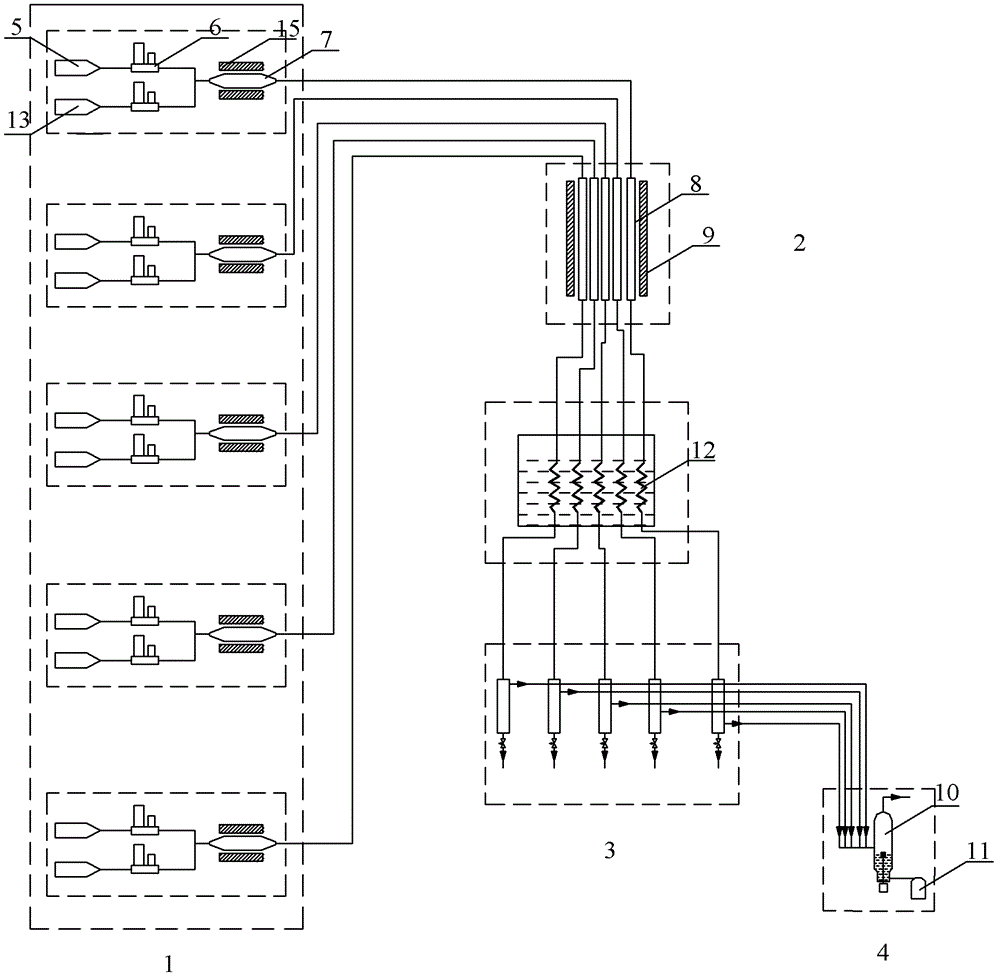

[0043] A multi-channel high-throughput catalyst evaluation device, comprising a feed system 1, a reaction system 2, a heat exchanger 12, a sampling analysis system 3, and a product collection system 4 connected in sequence; there are five feed systems 1, respectively Comprising a gas phase feed channel 5 and a mass flow controller 6, a liquid phase feed channel 13 and a mass flow controller 6 and a mixing unit 7, the mixing unit 7 is provided with a heater 15 outside; the reaction system 2 consists of a multichannel reactor 8 and The external heating unit 9 of the multi-channel reactor 8 is composed of five branch reactors in the multi-channel reactor 8, and the feed system 1 corresponds to each branch reactor of the multi-channel reactor 8; the product collection system 4 is one, A high pressure separator 10 and a product storage unit 11 are included.

[0044] Put the catalyst to be evaluated into each branch reactor; let the reaction samples A and B pass through the A mass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com