Flexible Rogowski coil used for detecting direct-current system short-circuit current and method for designing same

A Rogowski coil and short-circuit current technology, applied in coils, circuits, measuring devices, etc., can solve the problems of Rogowski coil product failure, enameled wires are easily broken, lack of design methods, etc., and achieve the effect of improving mechanical life and structural process improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further details will be described below in conjunction with the accompanying drawings.

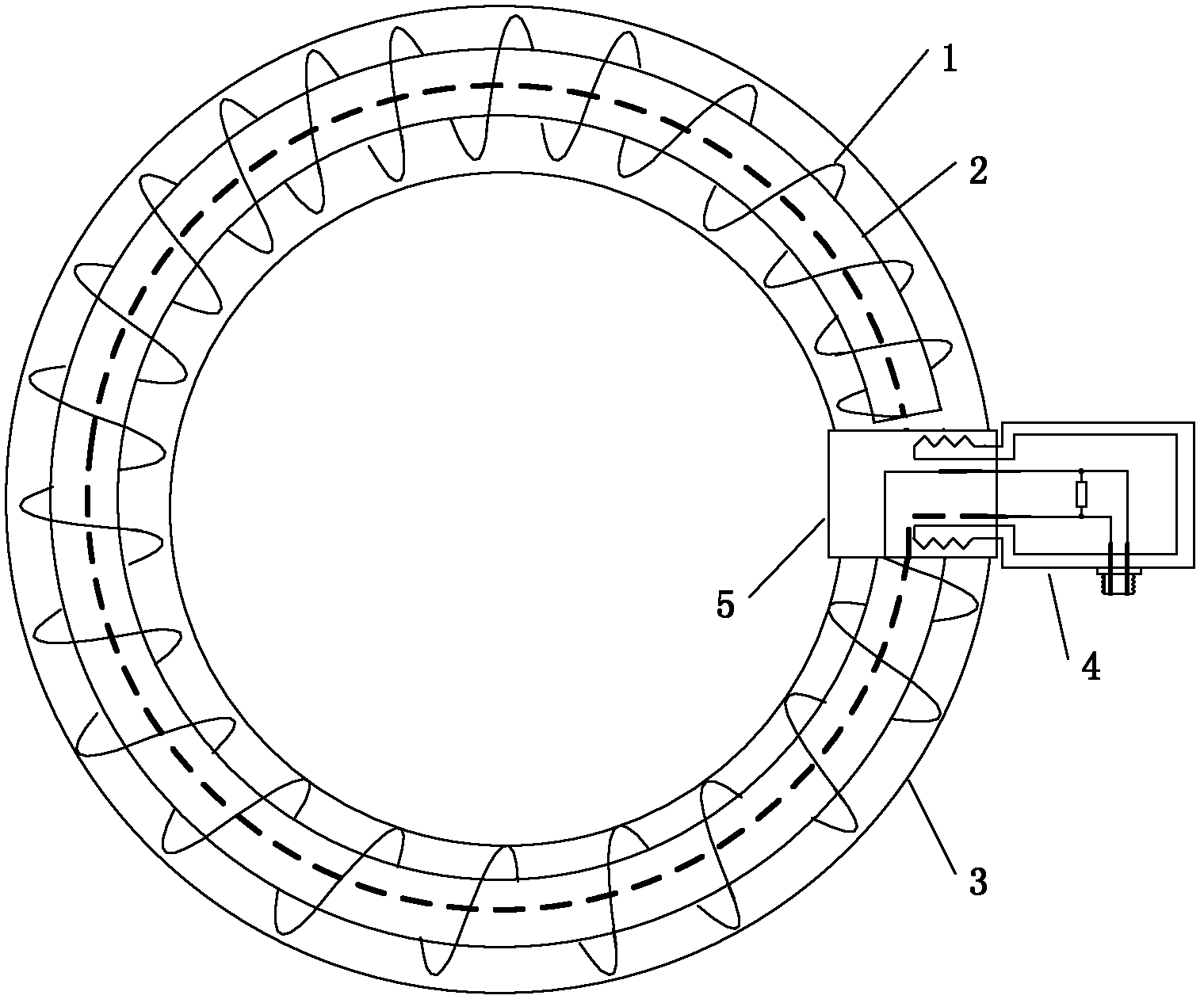

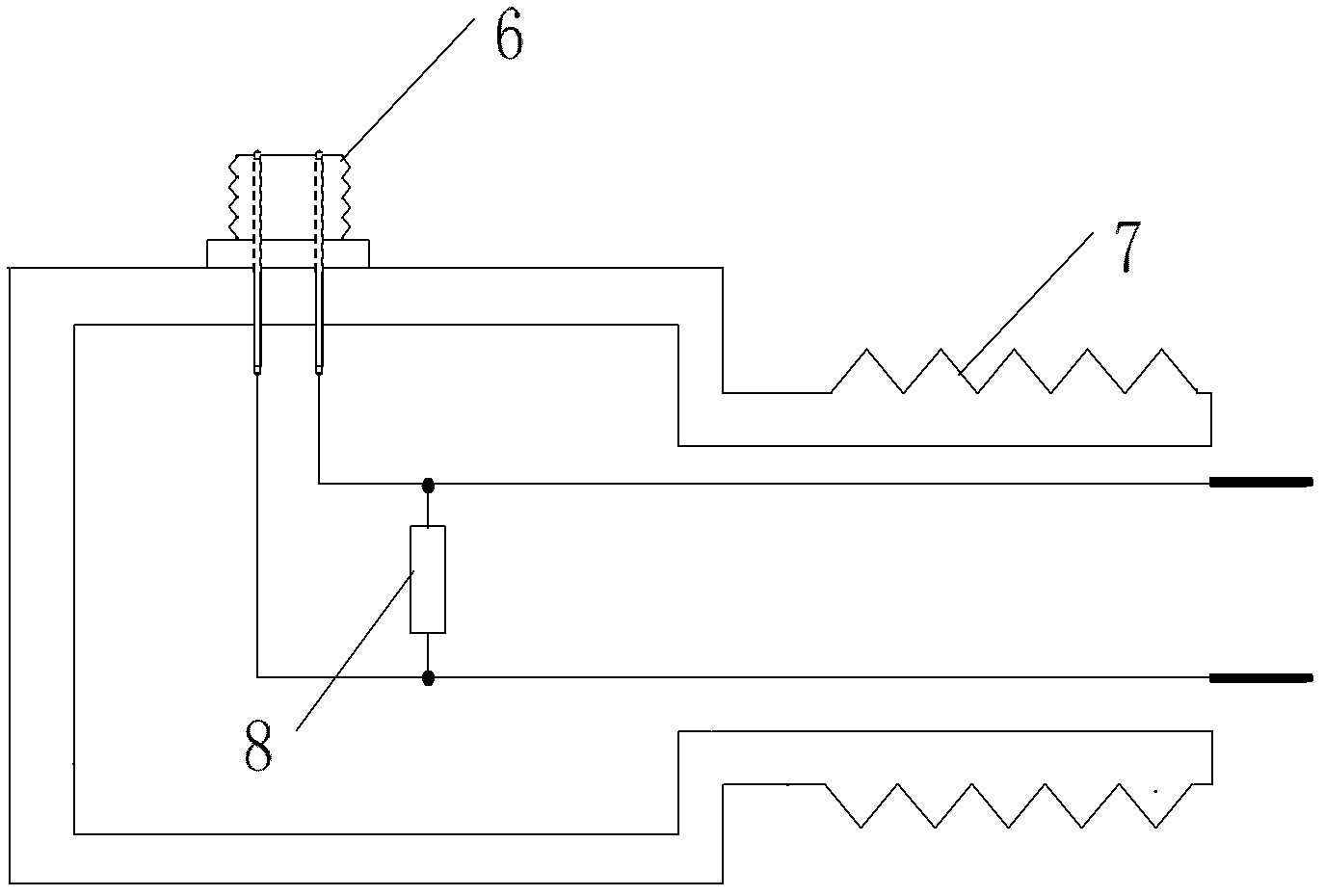

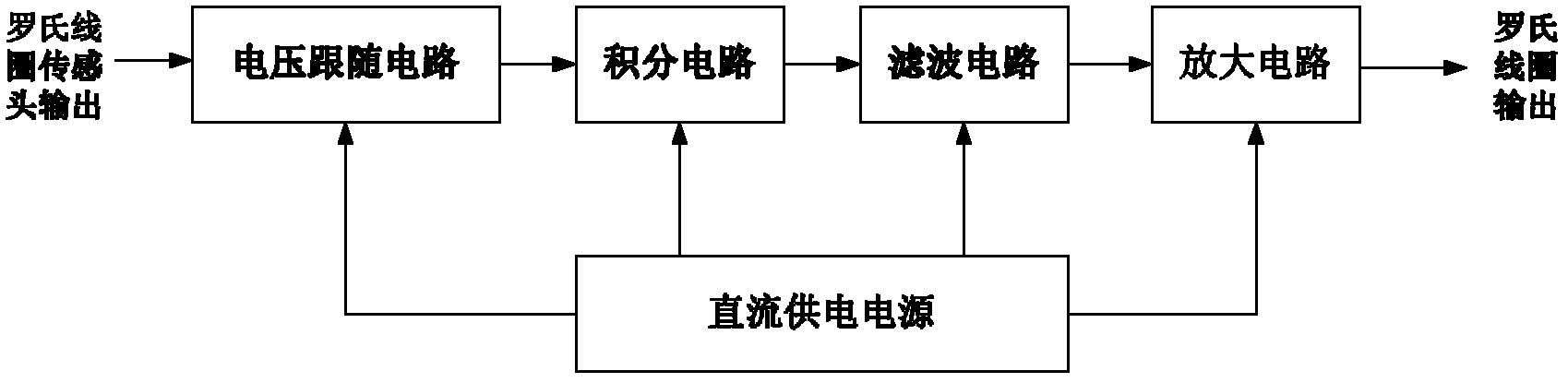

[0025] see figure 1 , the present invention includes a flexible skeleton 2, a coil and a loop 1, an outer insulating sleeve 3, a sampling resistance module 4 and a plug-in interface 5; the coil is evenly wound on the flexible skeleton 2, and the coil loop is embedded in a flexible The geometric center of the skeleton 2, the two ends of the winding wire are drawn out after passing through the sampling resistor module 4 through the plug-in interface 5; the entire Rogowski coil forms an open ring, and the head and the end are connected through the plug-in interface 5 when in use, and the Rogowski coil leads out the signal Connect with the post-integration circuit. In the Rogowski coil loop winding process adopted in the present invention, the loop wire and the coil winding itself are composed of a single wire, specifically, the inner core of the silicone rubber cable is removed, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com