Parameter optimization method and system in sparking ball formation technique

An optimization method and ball-forming technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as no content found, and achieve the effect of reducing time and frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

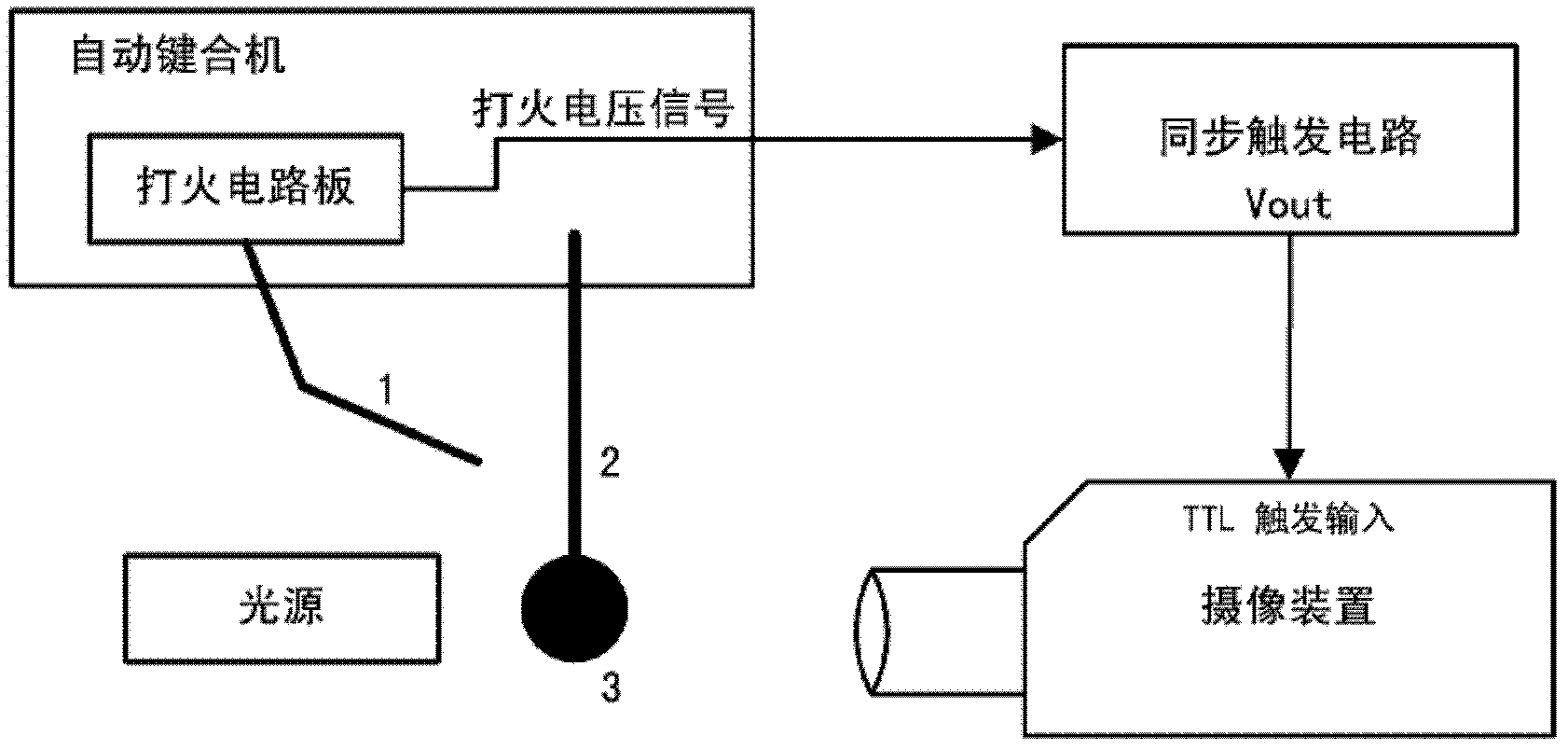

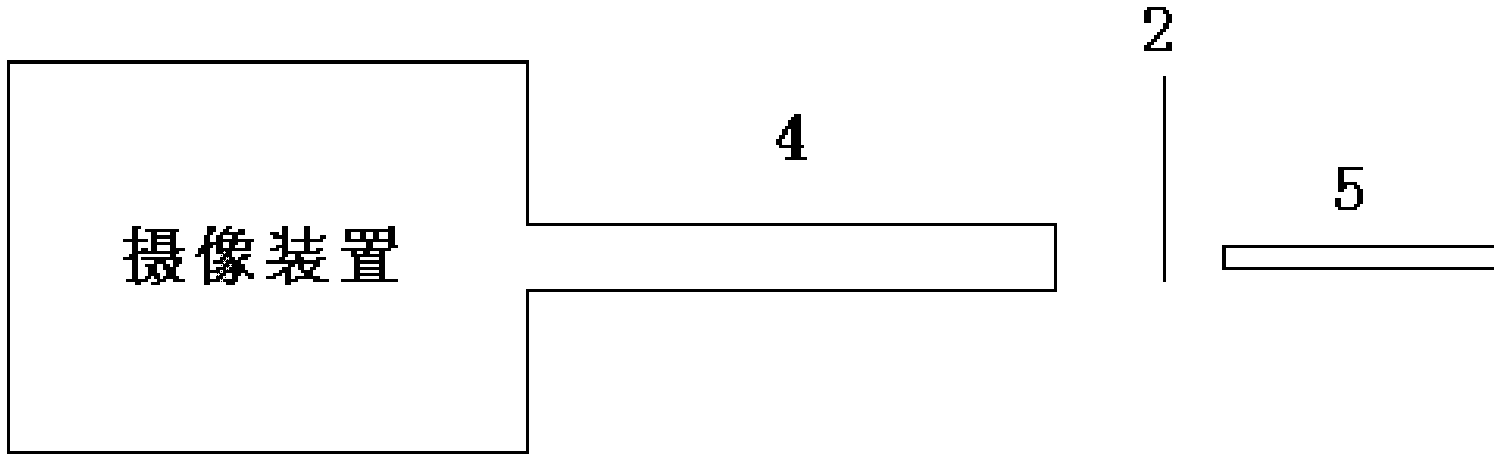

[0040]Embodiment 1: Monitoring of 25 micron diameter gold wire into ball process based on high-speed camera

[0041] Photron FASTCAM SA1.1 high-speed camera acquisition system is adopted. The most notable feature of this system is that it can shoot and record at high speed and obtain clear image data. The fastest frame number reaches 6.5×10 5 Frames per second, maximum resolution up to 1024×1024 pixels, shooting time up to seconds. The lens adopts the confocal optical system of Zoom 6000 from Navitar Company. The optical magnification of this optical system used in this patent is 20 times. Connect with Photron FASTCAM SA1.1 high-speed camera acquisition system through standard C port.

[0042] Work process of the present invention:

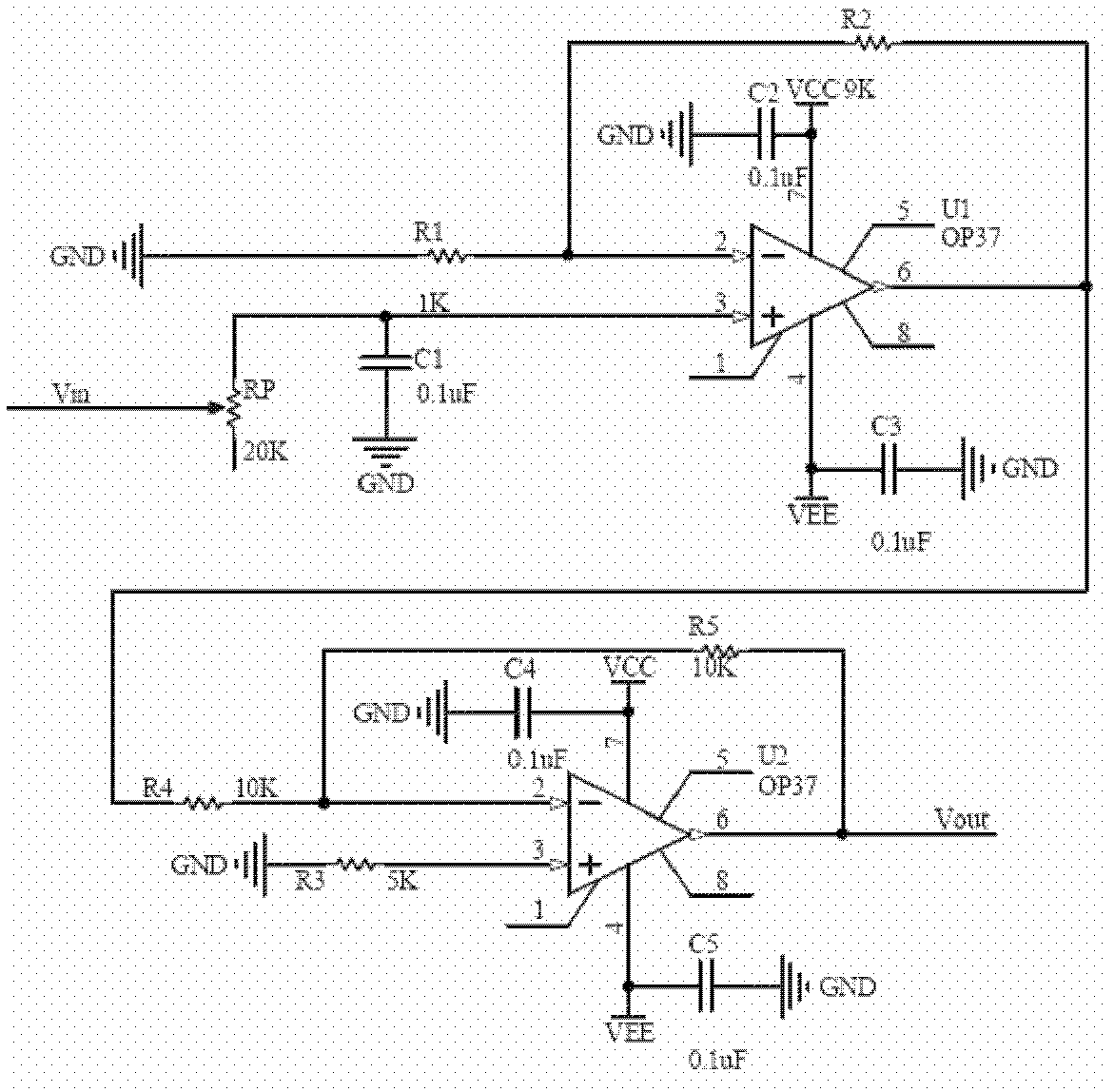

[0043] First connect the ignition voltage signal to the reverse amplification circuit, after passing through this circuit, the voltage signal is reversed and amplified by 10 times, and then this signal is connected to the high-speed camera, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com