Electromagnetic induction heating round roll with uniform surface temperature

An electromagnetic induction heating and surface temperature technology, applied in induction heating, induction heating devices, etc., can solve the problems of poor product quality, poor temperature uniformity, high power consumption, etc., and achieve low cost, high heating efficiency, and good temperature uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

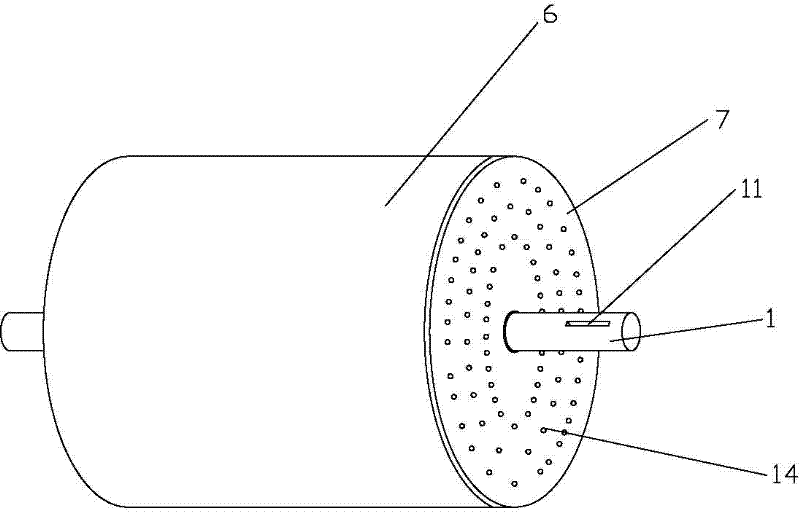

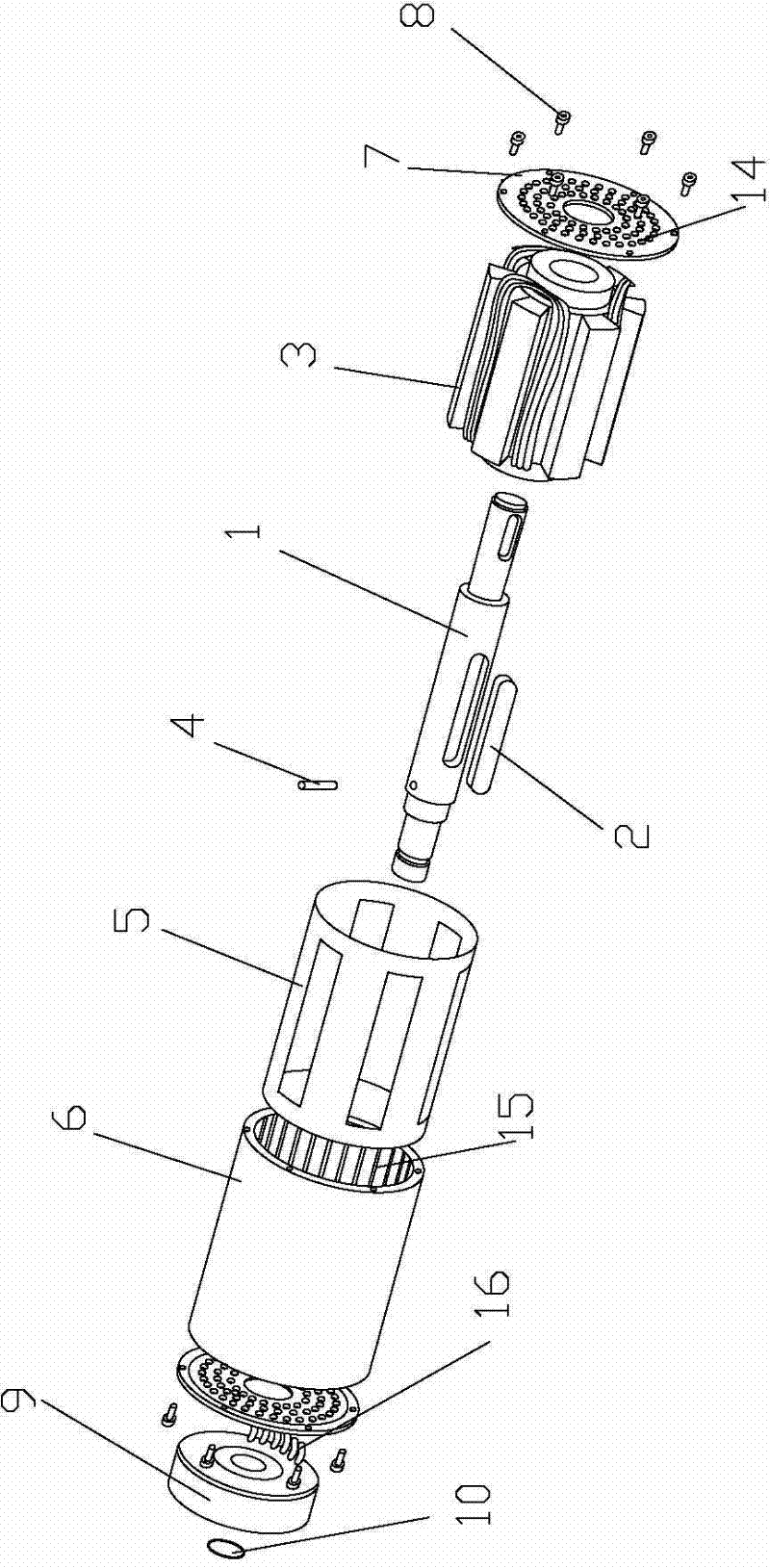

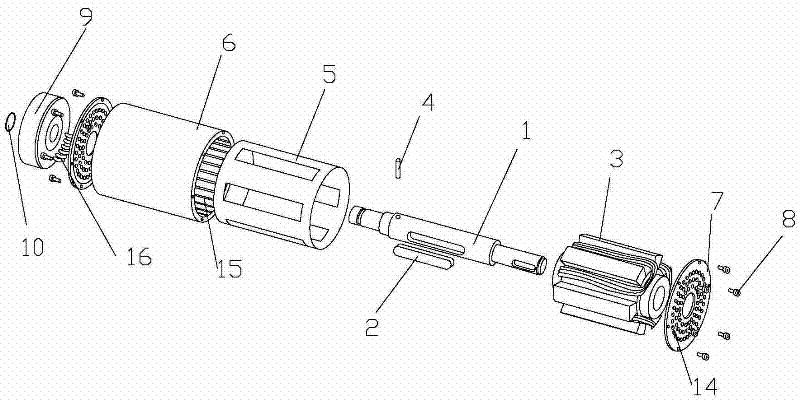

[0010] Depend on figure 1 , 2 As shown, the present invention comprises a hollow circular roller body, a rotating shaft, an electromagnetic induction coil and a magnetic pole body. Protrude from the center hole of both ends of the cover. The rotating shaft 1 is equipped with a magnetic pole body 3 in the hollow circular roller body. The electromagnetic induction coil 13 is installed in the magnetic pole body. There is a conductive strip 15 formed between the grooves in the hollow circular roller body. The magnetic pole body 3 A heat insulating cover 5 is sleeved in the hollow circular roller body, and a conductive slip ring 9 is installed outside the end cover on one end of the rotating shaft, and the conductive slip ring 9 is connected to the electromagnetic induction coil 13 through a wire 16 .

[0011] In order to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com