Feeding device of tin-cutting and sending integrated chip mounter

A chip mounter and tin-feeding technology, applied in the field of tin-cutting and tin-feeding integrated chip mounter feeding equipment, can solve the problems of complicated packaging, restricted production efficiency, and expensive unit price of tin particles, and achieve simple structure and convenient installation and docking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

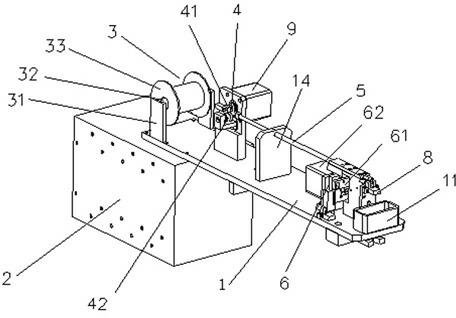

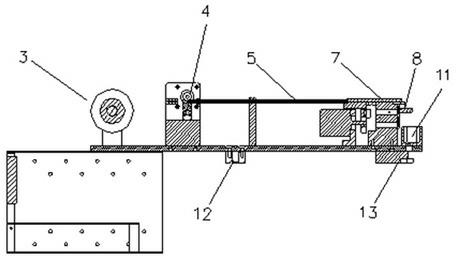

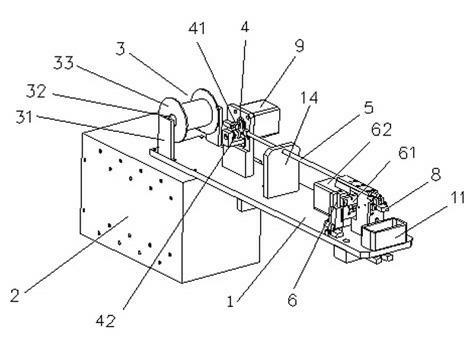

[0021] Such as figure 1 and figure 2 As shown, a feeding device for a tin-cutting and tin-feeding integrated placement machine, which includes a main mounting board 1 and a control electric box 2, is characterized in that, the main mounting board 1 is respectively provided with coils in the order of front and back. Tin device 3, tin wire transmission wheel 4, guide pipe 5, tin cutter 6, tin particle guide groove 7 and tin particle positioning sensor 8, tin wire transmission wheel 4 is connected with transmission wheel motor 9, and guide pipe 5 straddles the tin Between the wire drive wheel 4 and the tin cutter 6, a tin particle guide groove 7 is arranged between the tin cutter 6 and the tin particle positioning sensor 8, and the control electric box 2 is connected with the transmission wheel motor 9, the tin cutter 6 and the tin particle respectively. The positioning sensor 8 is electrically connected, the main mounting plate 1 is provided with a plurality of support plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com