Apparatus and method for separation of phases in a multiphase flow

A technology of multiphase flow and eddy current, which is applied in the field of equipment and methods for separating phases in multiphase flow, can solve problems such as inability to treat wastewater, and achieve improved separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

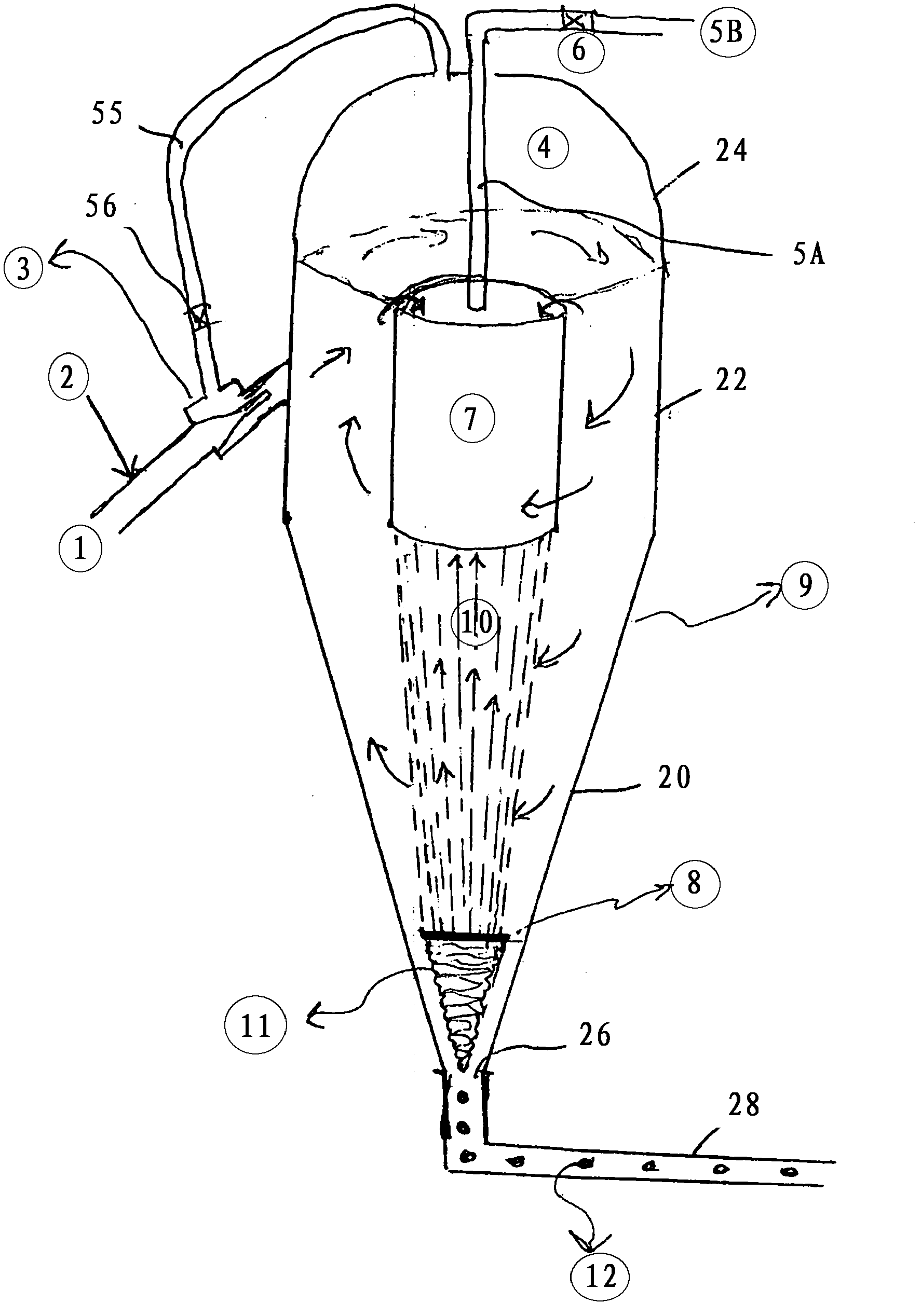

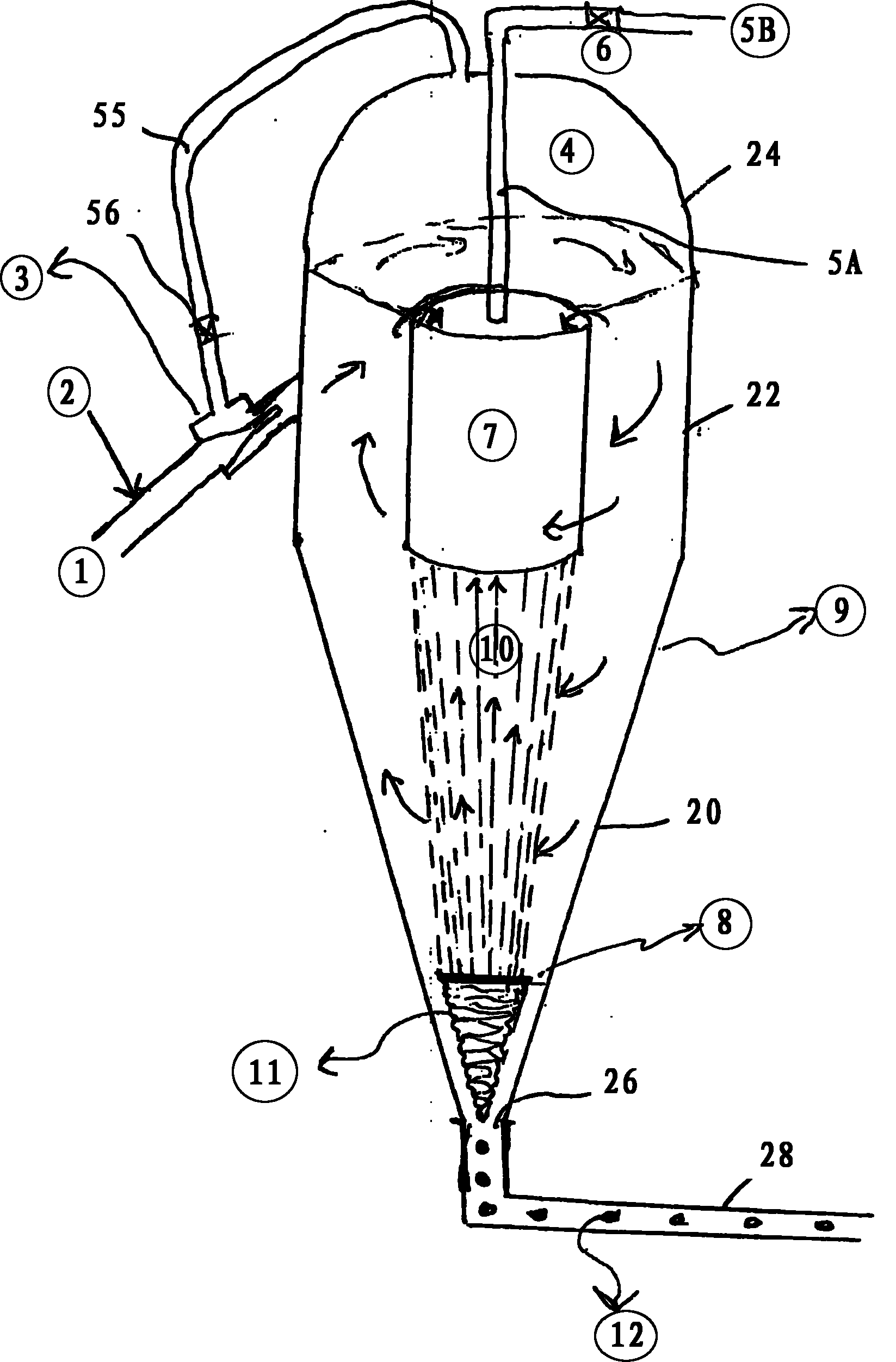

[0078] figure 1 A device according to the invention is shown which is used to carry out the method according to the invention.

[0079] The apparatus comprises a treatment tank 9 (flotation cyclone tank) having a conical bottom portion 20 (like a cornet), an upper cylindrical tank portion 22, and an upper top portion 24 which Can be dome shaped. This is just an example of shapes. In the bottom tip of the conical section 20 there is an outlet 26 to which a draft tube 28 is fitted.

[0080] In the upper part and in the middle of the tank 9 there is arranged a general vortex director 7 which is a cylinder for influencing the flow and separation in the tank 9 in an advantageous manner.

[0081] In the upper half of the tank 9 there is a pipe 1 for addition arranged tangentially for the tangential inlet of the fluid to be treated. From the top of the vortex director 7 is arranged a pipe 5A extending upwards and through the upper top part 24 to the outside. This pipe continues ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com