System and methods for purifying biological materials

A substance and impurity technology, applied in the field of systems for purifying fluids, to solve problems such as retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

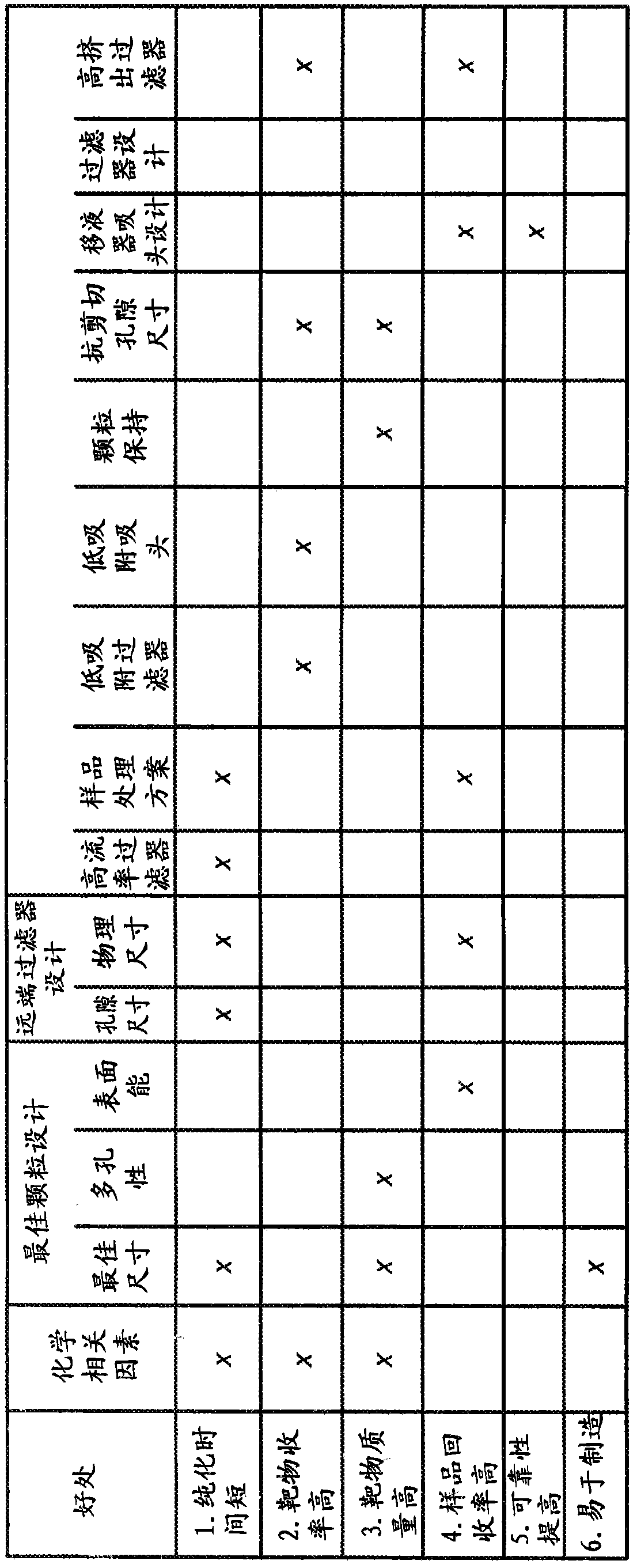

[0514] 6.1 Example 1: Preferred embodiment of fluid sample purification system

[0515] This example illustrates a preferred embodiment of the fluid sample purification system. The system contains a distal particle retainer that efficiently retains particles, minimizes fluid flow resistance, consistent tip-to-tip flow resistance, reduces sample processing time, minimizes retention of sample fluid, improves product manufacturability, and reduces product manufacturing costs decreased and the sample quality improved.

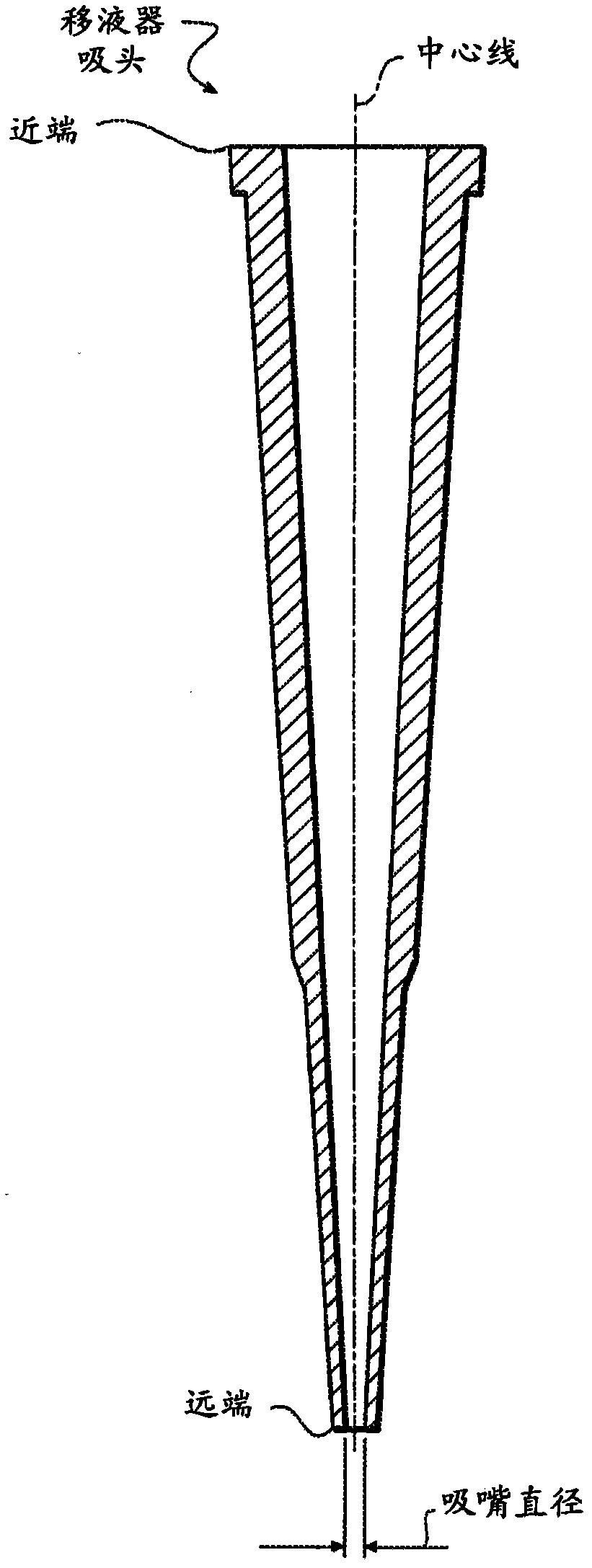

[0516] This example describes an improved pipette filter design that can be used in a fluid sample purification system. Specific features of this filter include: very low fluid flow resistance, consistent fluid flow resistance, uniform pore size, low sample retention and low cost. Unlike prior art fluid sample purification systems, embodiments of the present invention fluid sample purification system with this filter design have components within the pipette tip ...

Embodiment 2

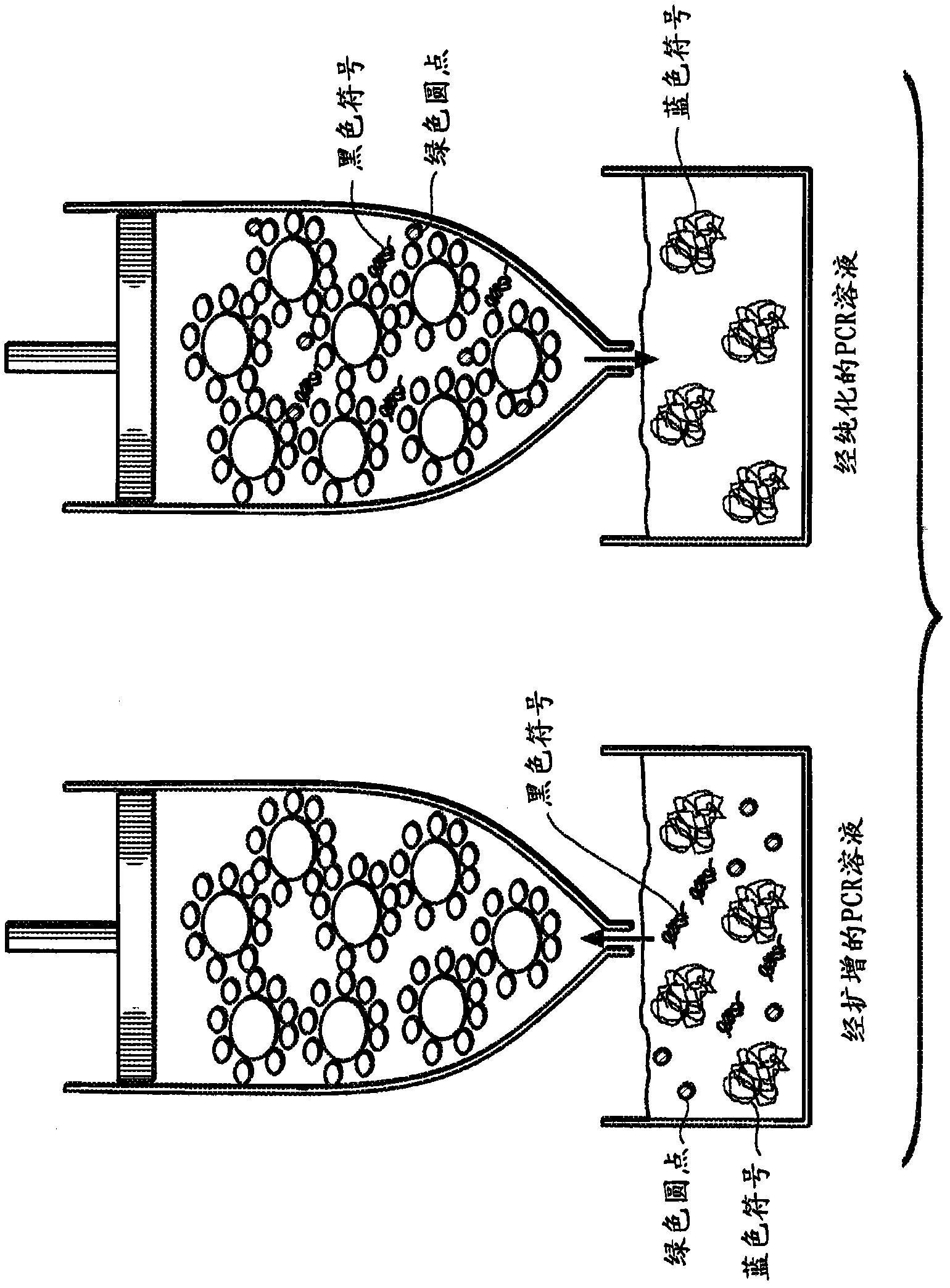

[0534] 6.2 Example 2: Fluid sample purification system comprising pipette tips with mixing (reaction) chambers

[0535] This example describes another embodiment of a fluid sample purification system comprising a pipette tip with a different fluid mixing (or reaction) chamber design than described above. The mixing (reaction) chamber has a low slenderness ratio, a design that allows for a more efficient interaction between the aspirated / dispensed sample and the adsorbent material. Figure 40b Shown containing loosely packed particles (not shown but with figure 2 similar) and distal particle holder B and designed pipette tip A with a mixing chamber C of low height L. ( Figure 40a A typical prior art pipette tip configuration is shown). There is a transition zone from the nozzle diameter d to the pipette inner diameter D over a very short distance. Angle β is preferably about thirty degrees to help ensure an even transition of fluid flow from the pipette nozzle to the larg...

Embodiment 3

[0539] 6.3 Example 3: Fluid Sample Purification System Containing Pipette Tips with Minimal Internal Air Volume

[0540] This example describes another embodiment of a fluid sample purification system comprising a pipette tip with internally positioned pistons to minimize internal volume and generate high fluid sample aspiration and dispensing pressures.

[0541] The present fluid sample purification system embodiment comprises a pipette tip and a piston providing a minimum air volume within the pipette tip. Since the air contained within a pipette tip is a compressible fluid, the more air in the tip, the lower the pressure or vacuum that can be created within the pipette tip for a given displacement of the pipette piston. Since the pressure differential between the inside and outside of the pipette tip is the driving force for moving liquid into and out of the pipette tip, smaller pressure or vacuum differentials will result in lower sample flow rates. The sample flow rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com