Multi-station and multi-time hydraulic drawing press and processing method thereof

A hydraulic press and multi-station technology, which is applied in the field of hydraulic presses to achieve the effects of reducing floor space, increasing operating speed, and saving labor and turnover space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

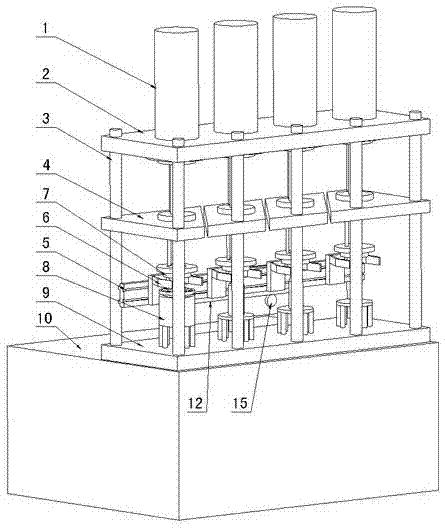

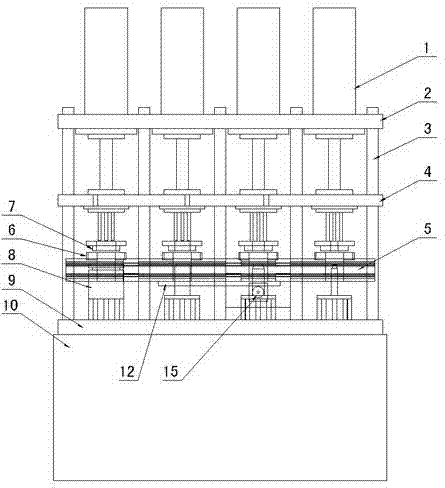

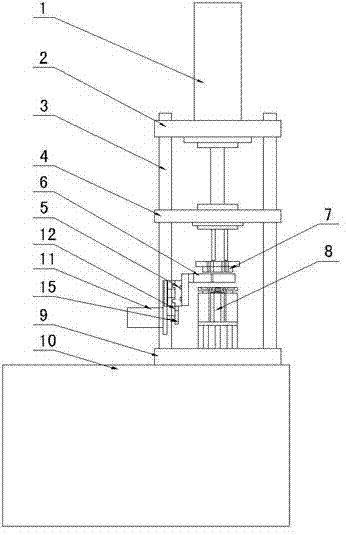

[0030] Figure 1 to Figure 8 As shown, the present invention creates a specific embodiment of a multi-station multi-channel stretching hydraulic press and its processing method, which includes an upper beam 2, a lower beam 9, a column 3, a machine base 10, a controller, and the upper beam 2 and the lower beam 9 are provided with four stretching units, each stretching unit corresponds to a station, the columns 3 of the stretching units on both sides are three-column structures distributed in right triangles, and the columns 3 of the middle stretching unit are Diagonally distributed two-column structure, the upper ends of the columns 3 of all stretching units are fixed to the upper beam 2, and the lower ends are fixed to the lower beam 9, so that the distance between the stretching units can be shortened, the floor space is greatly reduced, and it is convenient for workpieces to go up and down Transfer of work stations.

[0031] The stretching unit includes a master cylinder 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com