Printing method and device of water-base resin inkjet

An inkjet printing and water-based resin technology, applied in the field of inkjet printing, can solve the problems of poor precision and weak adhesion, and achieve the effects of improved precision, improved printing accuracy and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

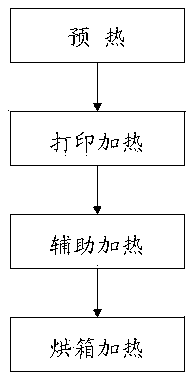

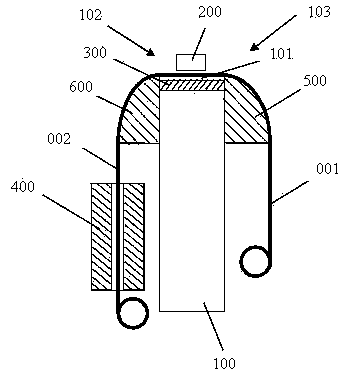

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the printed product carrier is coated paper for printing, the preheating temperature for the paper is 40°C, the heating temperature during printing is 40°C, the auxiliary heating temperature after printing is 40°C, and the oven heating temperature is 40°C. ℃. The time of each heating process is 4s, 5s, 6s, 10s respectively.

[0028] Afterwards, the firmness of the printed matter was detected by the Scotch tape ink transfer method, and the accuracy of the printed matter was detected by the visual grading method. The results are shown in Table 1.

[0029] Table 1:

[0030]

Embodiment 2

[0032] In this embodiment, the printed product carrier is coated paper for printing, the preheating temperature for the paper is 40°C, the heating temperature during printing is 100°C, the auxiliary heating temperature after printing is 40°C, and the oven heating temperature is 40°C. ℃. The time of each heating process is 3s, 3s, 3s, 3s respectively.

[0033] Afterwards, the firmness of the printed matter was detected by the Scotch tape ink transfer method, and the accuracy of the printed matter was detected by the visual grading method. The results are shown in Table 2.

[0034] Table 2:

[0035]

Embodiment 3

[0037] In this embodiment, the printed product carrier is coated paper for printing, the preheating temperature for the paper is 40°C, the heating temperature during printing is 60°C, the auxiliary heating temperature after printing is 40°C, and the oven heating temperature is 40°C. ℃. The time of each heating process is 4s, 5s, 6s, 10s respectively.

[0038] Afterwards, the firmness of the printed matter was tested by the Scotch tape ink transfer method, and the accuracy of the printed matter was tested by the visual grading method. The results are shown in Table 3.

[0039] table 3:

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com