Cone-cycloid speed reducer for rotary brush type aerator

An aerator and reducer technology, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve problems such as inconvenient refueling, broken cage, short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

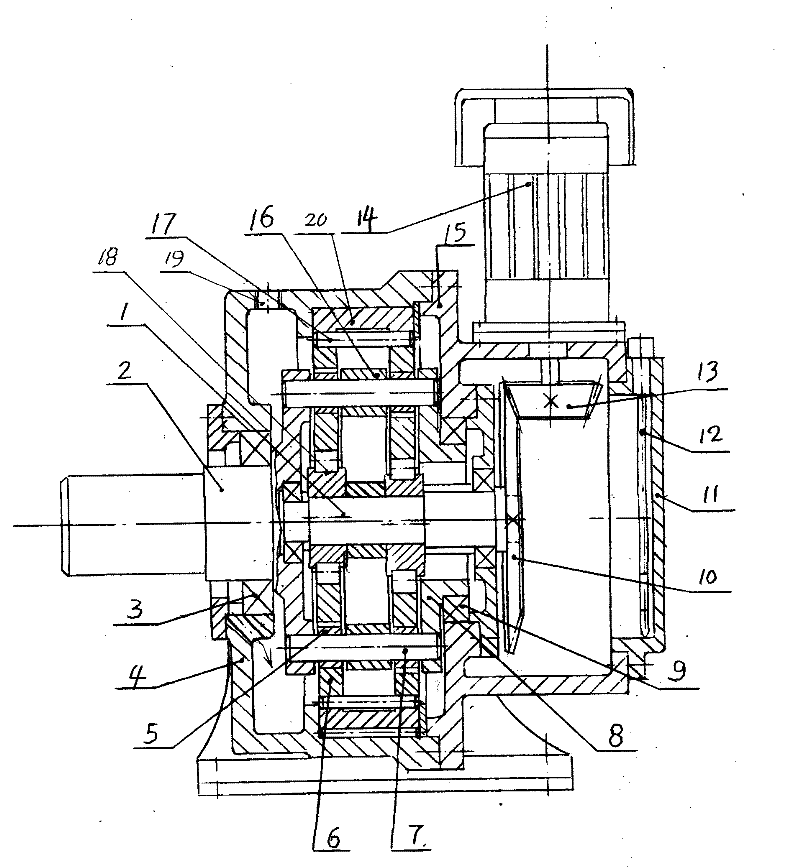

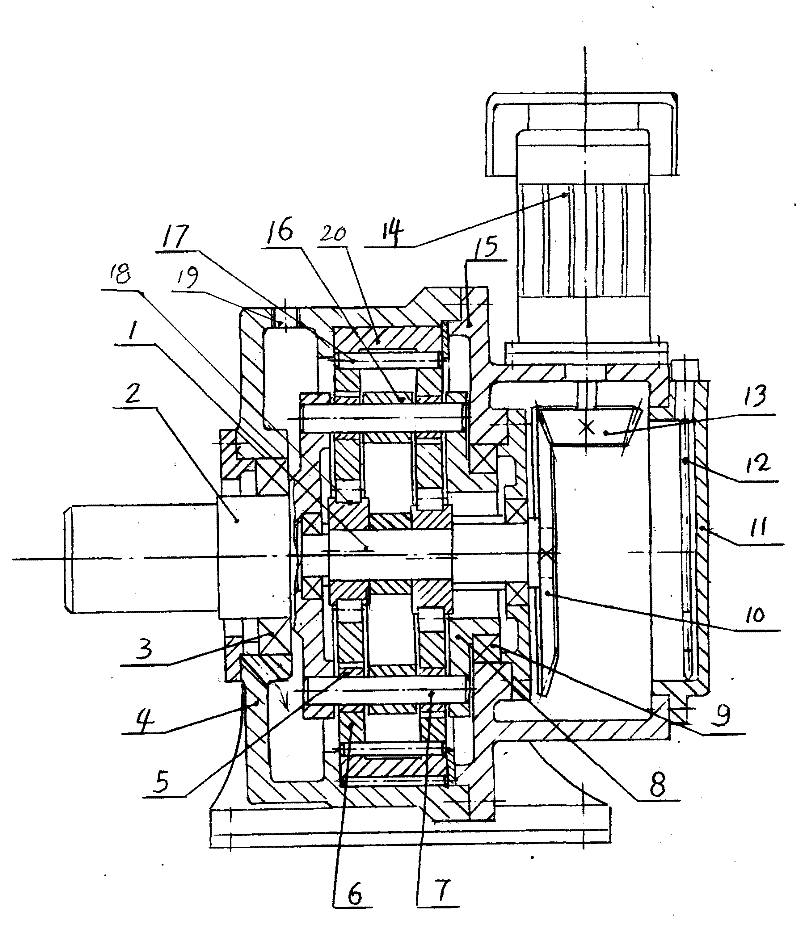

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

[0019] refer to figure 1 . A rotary brush type aerator cone-pendulum reducer, characterized in that: it is composed of a bevel gear pair installed in the small machine base (15) and a cycloidal transmission member installed in the machine base (4), wherein :

[0020] (A) The bevel gear pair is composed of a small bevel gear shaft (13) mounted on the small machine base (15) and a large bevel gear (10) connected to the input shaft (1) output extension end, and the small bevel gear shaft is connected to the motor (14 ), the small base (15) is connected to the end face of the base (4);

[0021] (B) Cycloidal transmission parts include input shaft (1), output shaft (2), cycloidal wheel (6), pintooth pin (17), eccentric bearing (18), pintooth housing (20) and W output mechanism , the pin gear housing (20) is connected to the inner hole of the machine base (4), so that the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com