Production technology of PTT fiber seamless knitted underwear with high wicking function

A technology of seamless knitted underwear and production process, which is applied in underwear, knitting, weft knitting and other directions to achieve the effects of antibacterial, mildew-proof, far-infrared and negative ion emission, super strong adsorption, and good far-infrared and negative ion emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

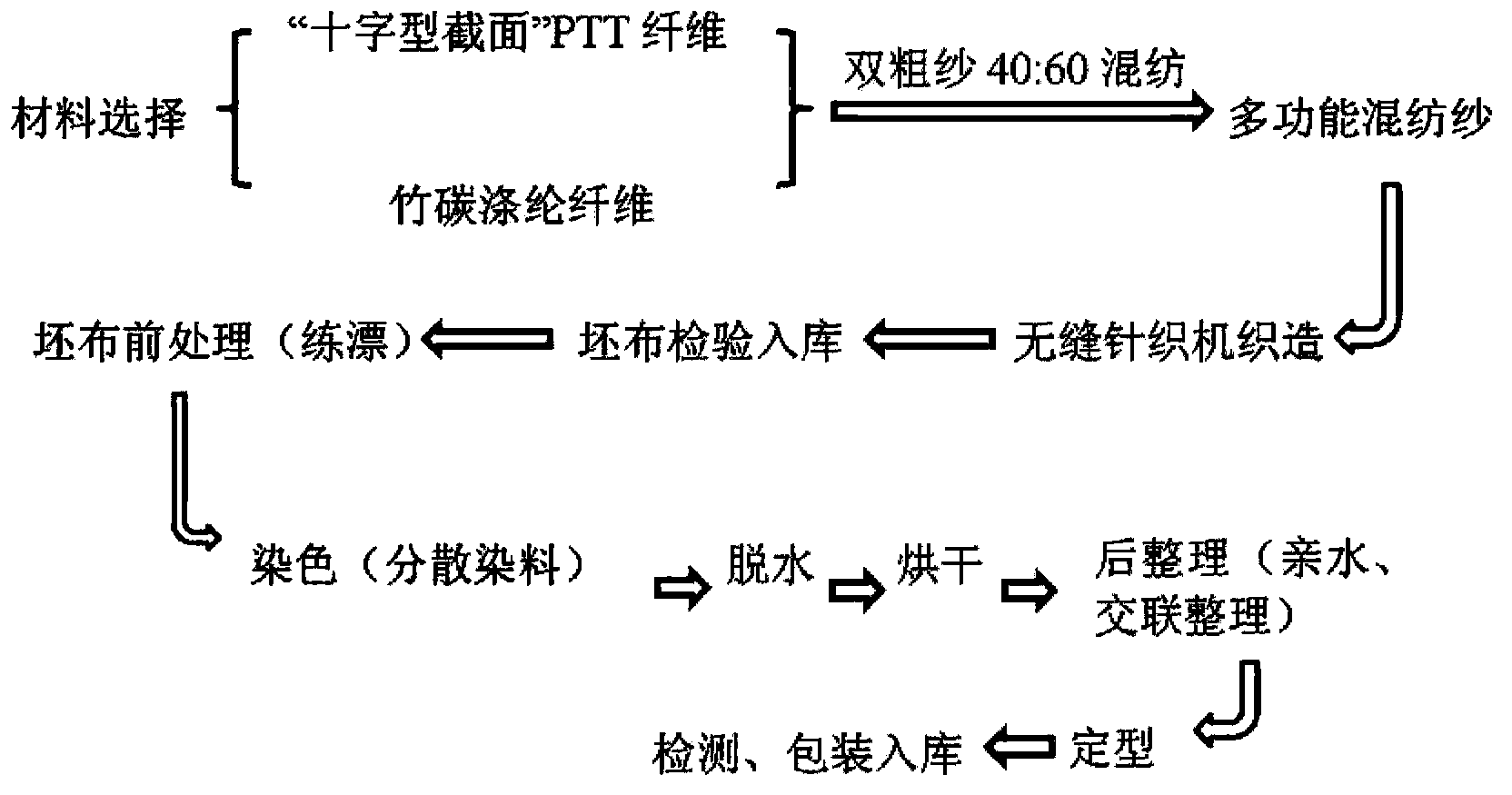

[0050] Such as figure 1 Shown, a kind of production technology of the PTT fiber seamless knitting underwear of high moisture-conducting function, comprises:

[0051] 1. Raw material selection

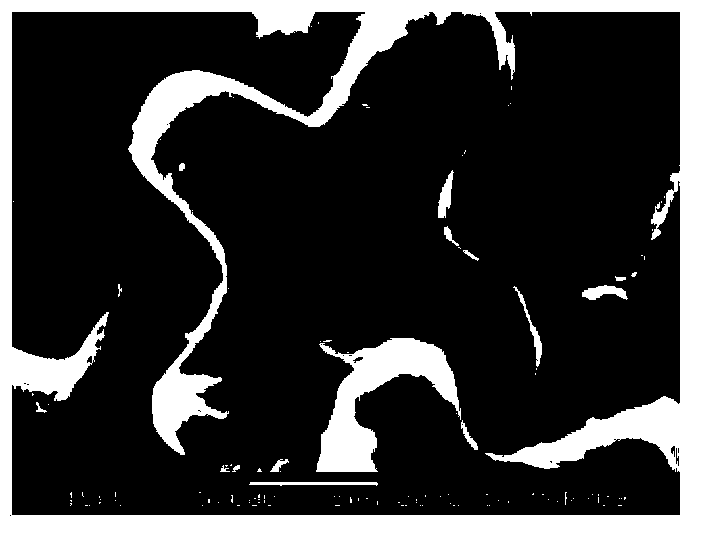

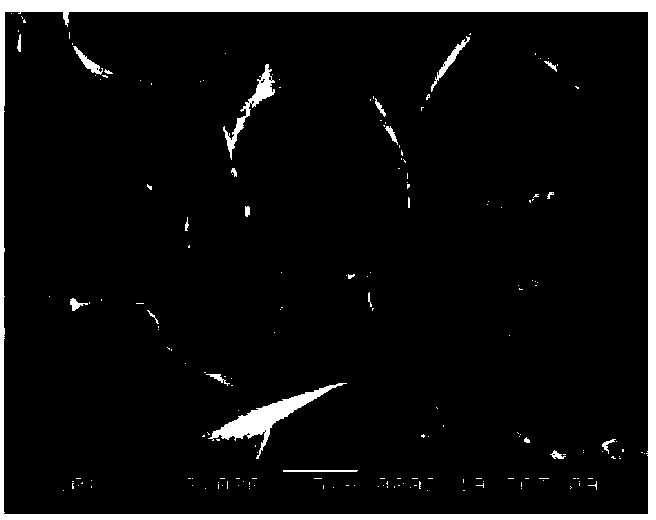

[0052] The cross-section PTT fiber produced by Donghua Haitian Company is used, the specification is 1.5dtex×38mm; the bamboo charcoal polyester fiber produced by Liaoyang Petrochemical Co., Ltd. is used, the specification is 1.67dtex×38mm.

[0053] 2. Preparation of blended yarn

[0054] The cross-section PTT fiber and bamboo charcoal polyester fiber have good length uniformity. The two are loosened, removed and fully mixed on the blowing line at a ratio of 40:60 to make a sliver. The fibers are fully mixed, and the two rovings are fed simultaneously in the spinning process, and finally the blended yarn of 18.2tex is obtained through automatic winding.

[0055] The technological process adopted is:

[0056]

[0057] 2.1 Cleaning process

[0058] The PTT fiber and bamboo charcoa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com