Polarizing plate protective film, polarizing plate and resistive touch panel

A technology of polarizer and protective film, applied in polarizing elements, transportation and packaging, electrical digital data processing, etc., can solve the problems of reduced polarization, changes, complex manufacturing processes, etc., to achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

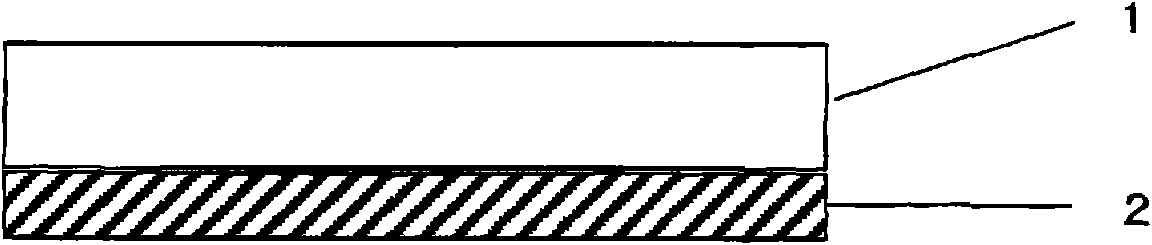

[0110] The preparation of embodiment 1 protective film

[0111] Using the melt molding T-die method, under the conditions of resin temperature 270°C and pulling roll temperature 140°C, cyclic olefin resin (copolymer of norbornene and ethylene, trade name "TOPAS6015", Topas Advanced polymers company manufactured, with a number average molecular weight of 45,800 and a glass transition temperature of 160°C) to obtain an optically isotropic film with a thickness of 200 μm.

[0112] Further, the obtained film was stretched 2.0 times in the width direction at 170° C. using a clip tenter type transverse stretching device to obtain a retardation film having a thickness of 100 μm and a retardation of 138 nm.

[0113] Then, in the air at a processing speed of 100W / m 2 · minute, corona discharge treatment was performed on both surfaces of the obtained optically isotropic film and retardation film, respectively, so that the wetting tension might become 500 micrometers N / cm (23 degreeC). ...

manufacture example 1

[0116] Production Example 1 Preparation of Polarizer

[0117] A polyvinyl alcohol film (trade name "Kuraray vinylon film (Kuraray vinylon film) VF-9X75R", manufactured by Kuraray, thickness 75 μm) was immersed in 5000 parts by weight of water, 35 parts by weight of iodine, and 525 parts by weight of potassium iodide. Parts of aqueous solution for 5 minutes to make it absorb iodine. Next, the film was uniaxially stretched 4.4 times in the longitudinal direction in a 4% by weight aqueous solution of boric acid at 45° C., and then dried under tension to obtain a polarizer (polarizing film) with a thickness of 17 μm.

Embodiment 2

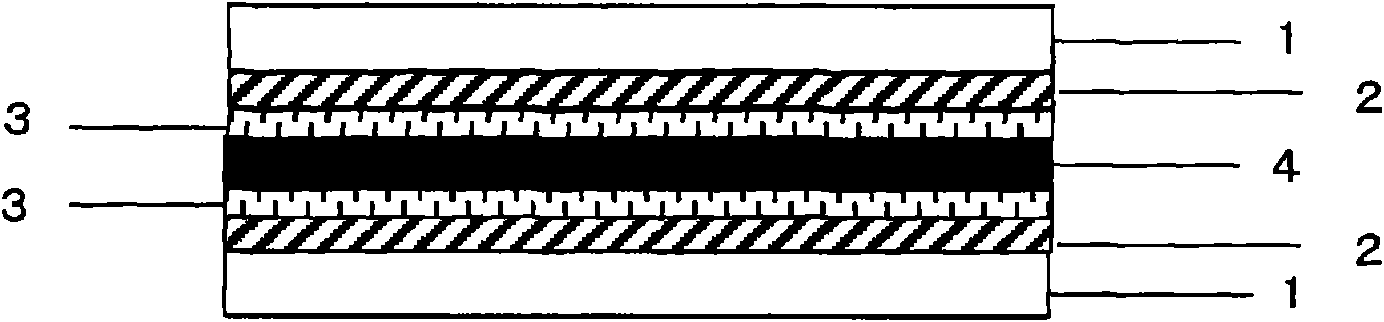

[0118] The preparation of embodiment 2 polarizer

[0119] As the binder, a 1.5% by weight aqueous solution of polyvinyl alcohol having an average degree of polymerization of 1,800 and a degree of saponification of 99% was used. Apply the adhesive to both sides of the polarizing film obtained in Manufacturing Example 1 so that the thickness after drying reaches 1 μm. The polarizing plate obtained in 1 was laminated in such a way that the silane coupling agent-coated surface of the protective film (1-1) was in contact, and was laminated on a rubber roller / metal roller (rubber roller diameter 200mm, metal roller diameter 350mm, linear pressure 10kg / cm) were clamped (two pumps), and dried in an oven at 40°C for 24 hours.

[0120] In addition, one side of the polarizing film obtained in Production Example 1 was passed through the silane coupling agent layer of the polarizer protective film (1-1) obtained in Example 1, and the other side of the film was passed through the silane c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com