Synthetic method for fluororubber

A synthetic method and technology of fluororubber, applied in the field of fluororubber, can solve the problems of low Mooney value of fluororubber and inability to adapt to higher performance requirements, and achieve good vulcanization performance, good oil resistance and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

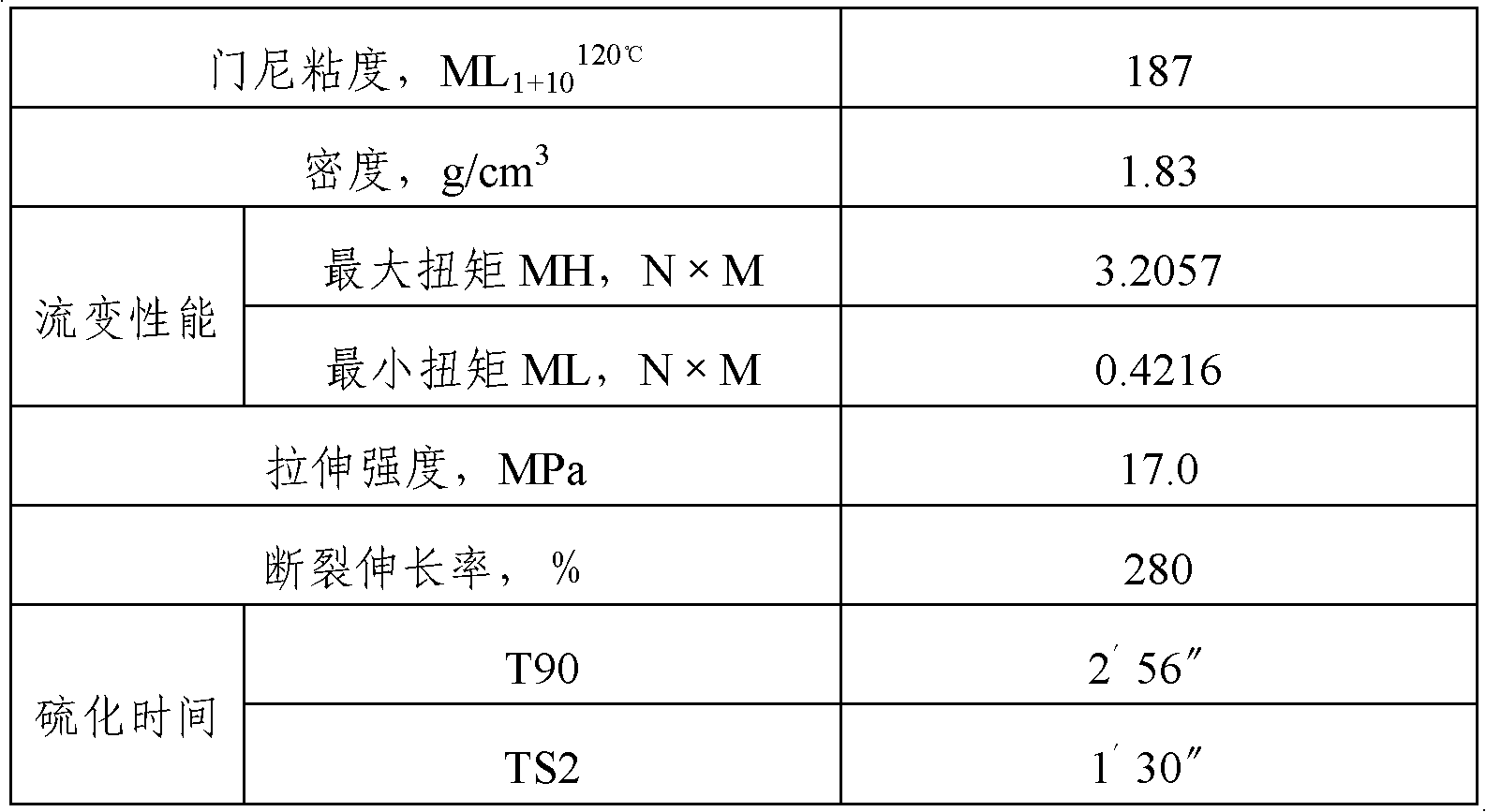

Embodiment 1

[0040] The batch free radical emulsion polymerization of the present invention is carried out in a 50L autoclave to prepare fluororubber. Add 30L of non-ionized water, 500g of 5wt% ammonium perfluorooctanoate aqueous solution, 40g of pH regulator disodium hydrogen phosphate into the reactor, and replace the air in the vapor space of the reactor with nitrogen first, and then replace it with mixed monomers to make the oxygen content less than 20ppm, the reactor was raised to 120°C. A diaphragm compressor was used to add the above monomer mixture to the reactor to increase the pressure to 3.5Mpa. After reaching 3.5Mpa, the reactor pressure controller is set to automatically operate at 3.5Mpa.

[0041] When the reactor pressure reaches 3.5 MPa, the stirring is started, the mixed monomers in the reactor are fully mixed, and then 100 g of initiator solution (5 wt%) is added to start the reaction. During the reaction process, the reactor pressure was maintained at 3.5MPa and the tempe...

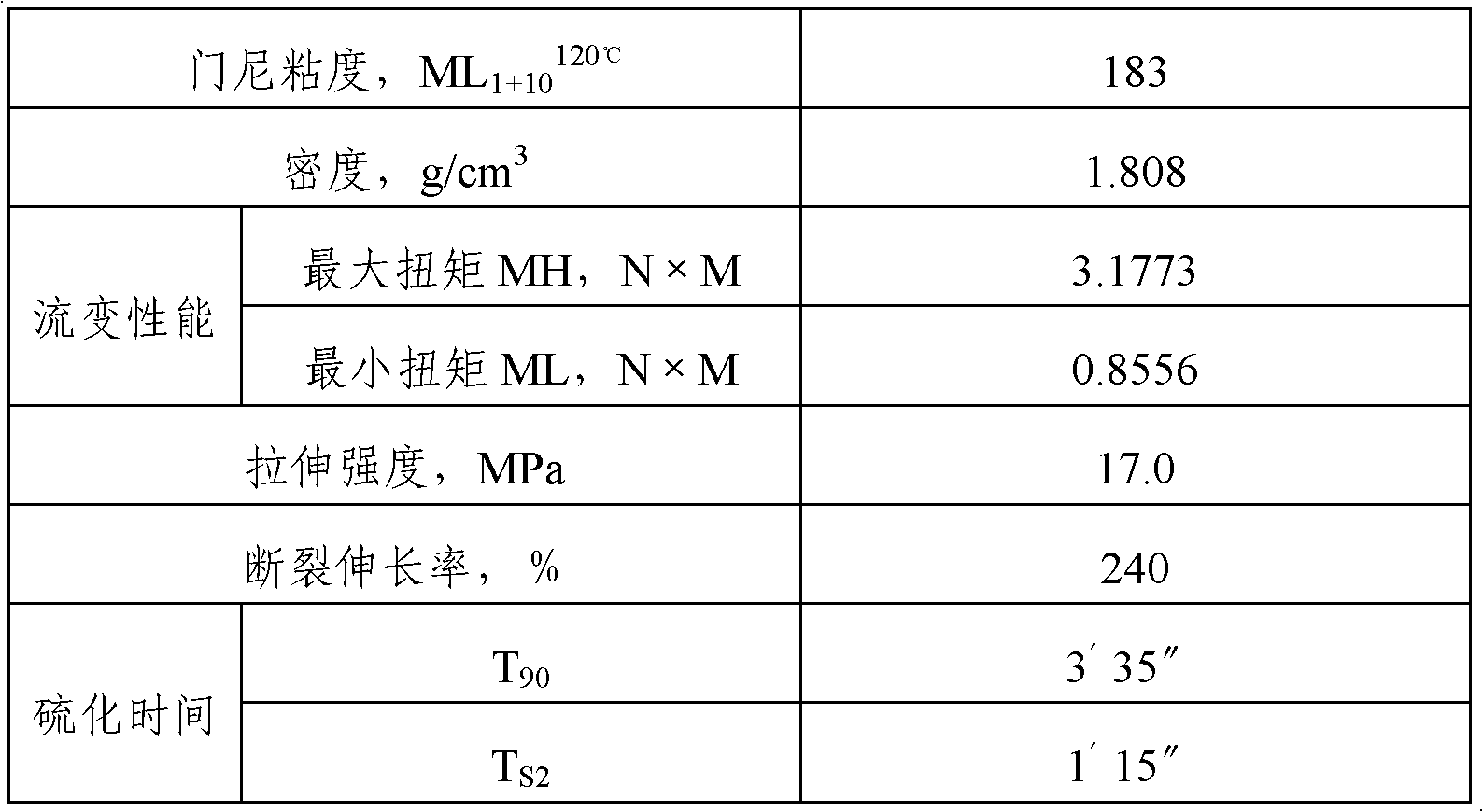

Embodiment 2

[0047] The batch free radical emulsion polymerization of the present invention is carried out in a 4000L autoclave to prepare fluororubber. Add 2200L of non-ionized water, 40Kg of 5wt% perfluorooctanoic acid amine aqueous solution, 2.8Kg of pH adjuster, disodium hydrogen phosphate into the reactor, and replace the air in the vapor space of the reactor with nitrogen first, and then replace it with mixed monomers to increase the oxygen content If it is less than 20 ppm, raise the reactor to 100°C. A diaphragm compressor was used to add the above monomer mixture to the reactor to increase the pressure to 3.5Mpa. After reaching 3.5Mpa, the reactor pressure controller is set to automatically operate at 3.5Mpa.

[0048] When the pressure of the reactor reaches 3.5MPa, the stirring is started, the mixed monomers in the reactor are fully mixed, and then 7Kg of initiator solution (5wt%) is added to start the reaction. During the reaction process, the reactor pressure was maintained at 3...

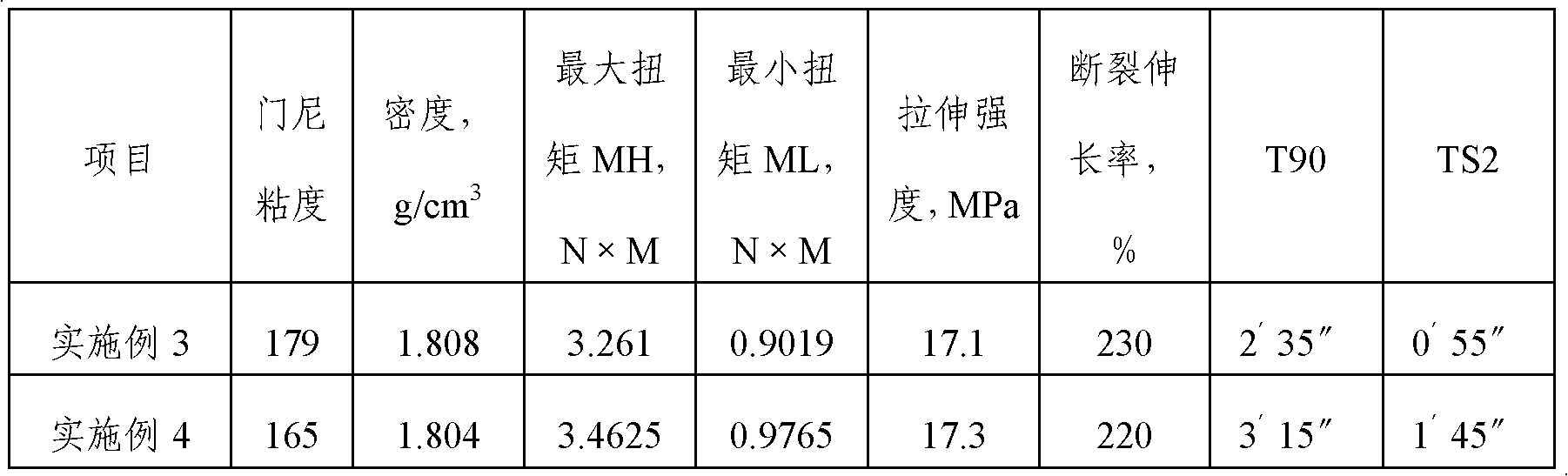

Embodiment 3

[0054] The polymerization temperature of Example 1 was changed to 90°C, and the other conditions remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com