Novel vacuum phase-change boiler

A vacuum and new technology, applied in the field of new vacuum phase change boilers, can solve the problems of large heat dissipation loss of the rear smoke box, low boiler thermal efficiency, and high exhaust gas temperature, saving installation space, high thermal conductivity, and good heat exchange effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

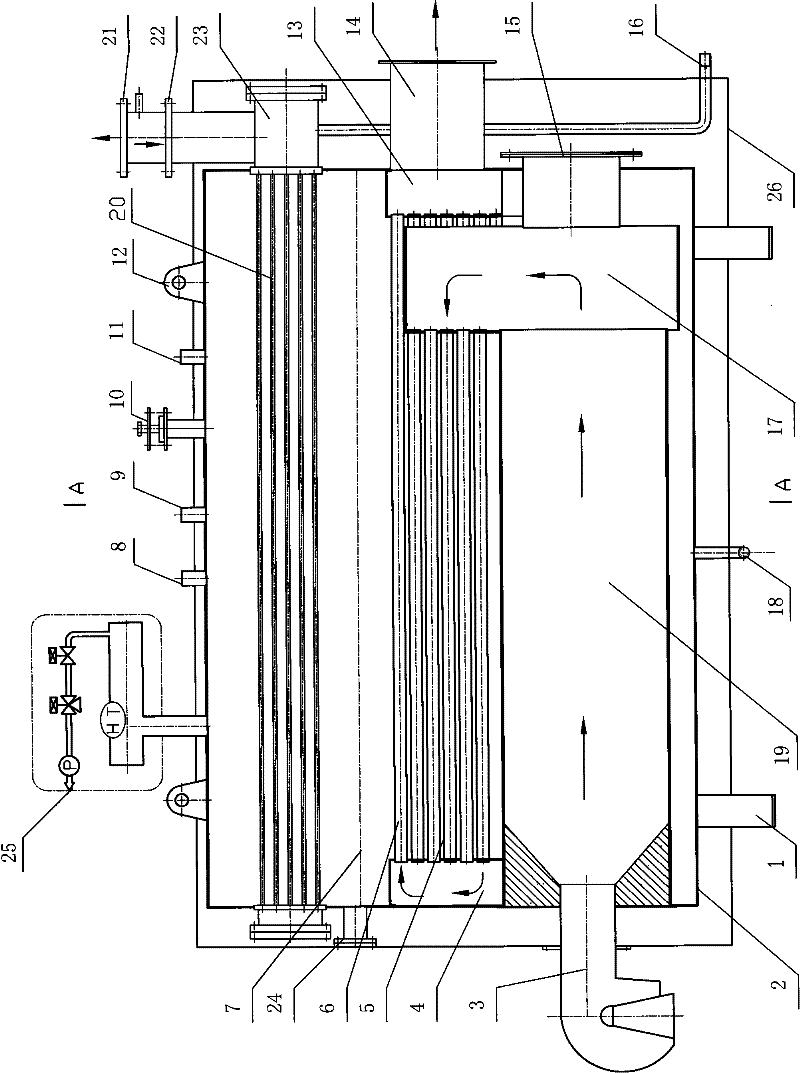

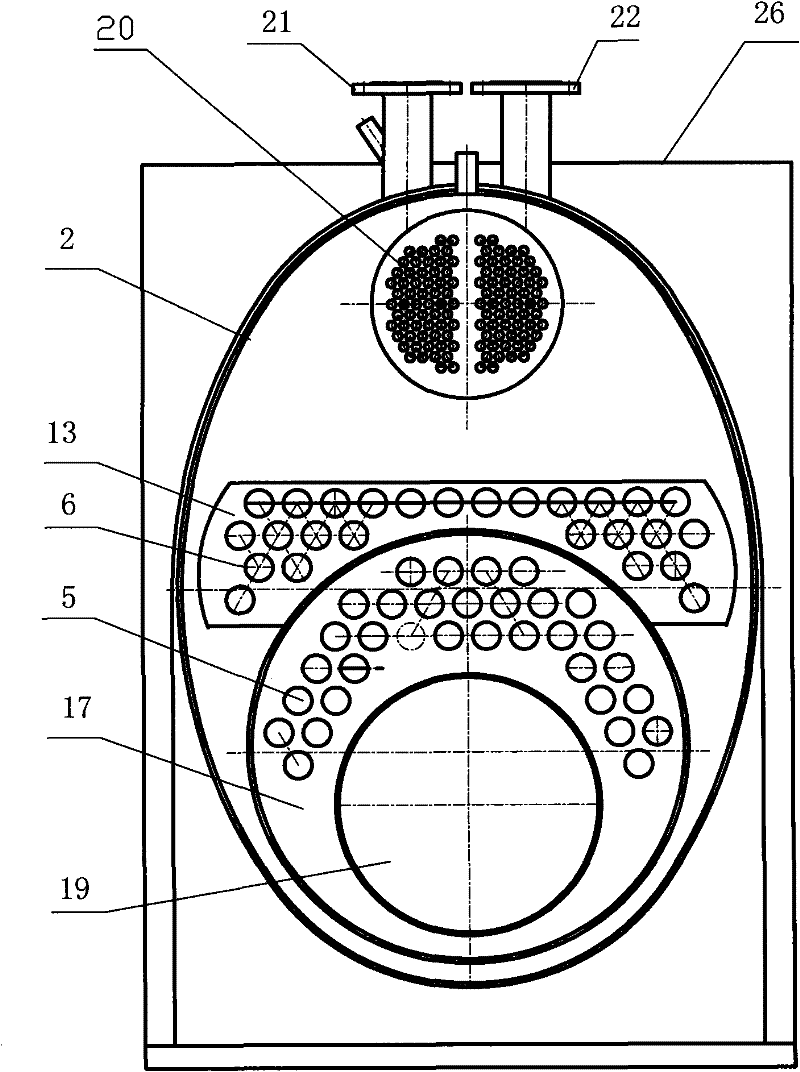

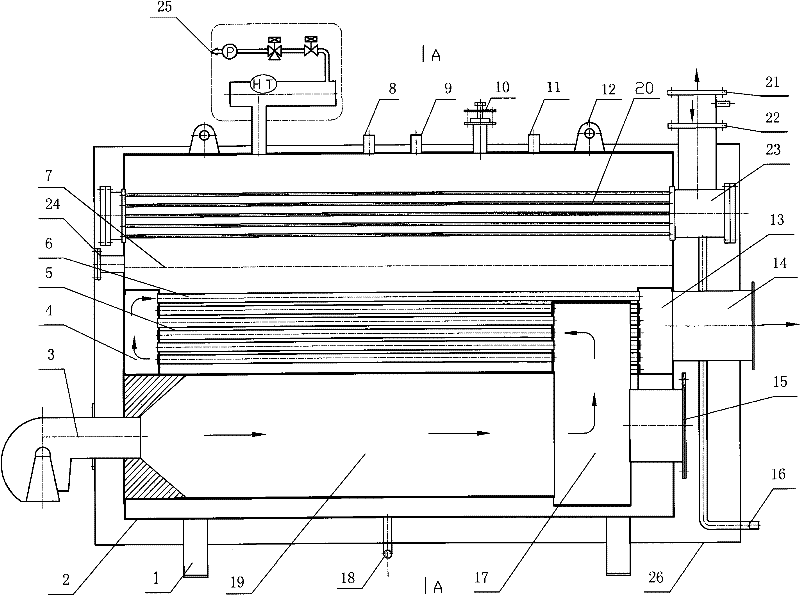

[0023] Such as figure 1 , figure 2 As shown, the new vacuum phase change boiler is composed of a burner 3, a body, and a control cabinet, wherein the body is provided with the following main components: an oval shell 2; a vacuum device 25, a water temperature sensor port 8, and a pressure sensor are arranged above the shell 2 Port 9, pressure protection device 10, water level sensor port 11; lifting lug 12; base 1 and sewage outlet 18 under the shell 2; burner 3, liquid level sight glass 24, submerged front smoke Box 4, liquid level sight glass 24 and submerged front smoke box 4 are connected to the front of the shell; behind the shell 2 are submerged rear smoke box 13, smoke exhaust port 14, inspection port 15, water inlet 16, submerged rear smoke box The smoke box 13 is connected to the back of the shell 2; the shell 2 is provided with a cylindrical furnace 19 and a combustion chamber 17. , the shell 2 is connected to the rear, and the second return smoke pipe 5 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com