Gas-to-gas heat exchanger and waste gas incinerator integrating same

A technology of exchangers and incinerators, applied in the direction of incinerators, indirect heat exchangers, heat exchanger types, etc., can solve the problems of poor heat exchange efficiency, difficult cleaning and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

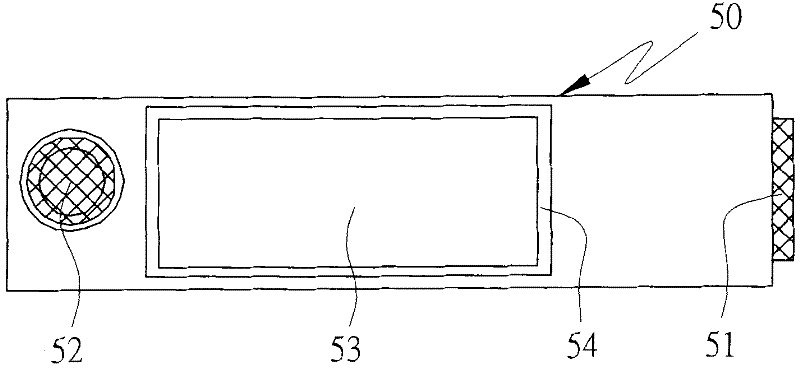

[0041] First, see Figure 3 to Figure 5 As shown, the first embodiment of the air-to-air heat exchanger of the present invention includes: an outer box body 50, an inner hanging body 60a and a thermal insulation layer 80; wherein: the two ends of the outer box body 50 form There is a first gas inlet 51 and a first gas outlet 52 , and an insertion port 53 is formed at the top relative to the inner hanging body 60 a.

[0042] The inner hanging body 60a is provided with connecting flanges 64, 54 opposite to the insertion opening 53, so that the inner hanging body 60a is suspended and positioned inside the outer box body 50 through the insertion opening 53; The inner hanging body 60a has an upper box body 61 and a lower box body 62, and the two ends of the air guide tube bundle 63 are welded on the bottom plate of the upper box body 61 and the top plate of the lower box body 62, and the inside of the upper box body 61 is made of a partition plate. 612 separates the second type ga...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap