Method and system for measuring amplitude curve of mechanical vibration

A technology of amplitude curve and mechanical vibration, applied in the direction of measuring device, measuring ultrasonic/sonic wave/infrasonic wave, instrument, etc., can solve the problems of poor precision and low response frequency, and achieve accurate measurement amplitude value, high measurement response frequency, and system structure Simple Effects with Light Path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

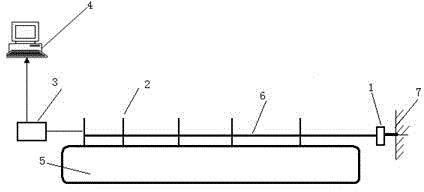

[0022] In order to solve the problems of poor precision and low response frequency existing in the existing amplitude curve measurement method of mechanical vibration, this embodiment provides a method for measuring the amplitude curve of mechanical vibration, including the following steps:

[0023] 1) Set the initial standard value;

[0024] 2), data collection;

[0025] 3) The data is saved and cleared.

[0026] Among them, the implementation process of step 1) is:

[0027] 1.1) Install a line laser module on a solid wall away from the test system;

[0028] 1.2) A plurality of acquisition boxes are arranged in sequence on the planned measurement points on the measurement axis of the system under test, and the planned measurement points are distributed in an approximately straight line along the measurement axis, and avoid the light sensitivity of the high-speed linear array CCD of the plurality of acquisition boxes The measurement points on the surface block the received ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com