Experimental apparatus for accurately measuring characteristic parameters of tool holder-main shaft combined part

A technology of characteristic parameters and experimental equipment, which is applied in the direction of measuring equipment, vibration testing, machine/structural component testing, etc., can solve the problems of inaccurately reflecting connection conditions and large errors in identification results, etc., and achieves small quality and reduced noise , the effect of improving the recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

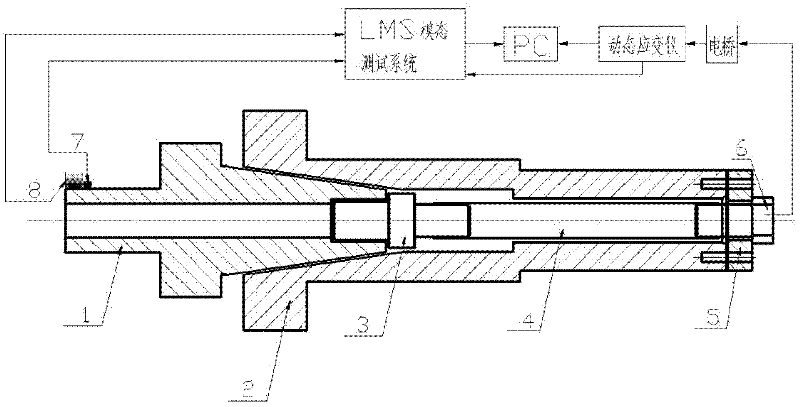

[0016] The following is attached with the manual figure 1 - attached Figure 4 The present invention is described further:

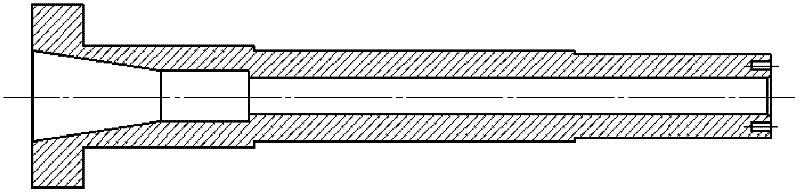

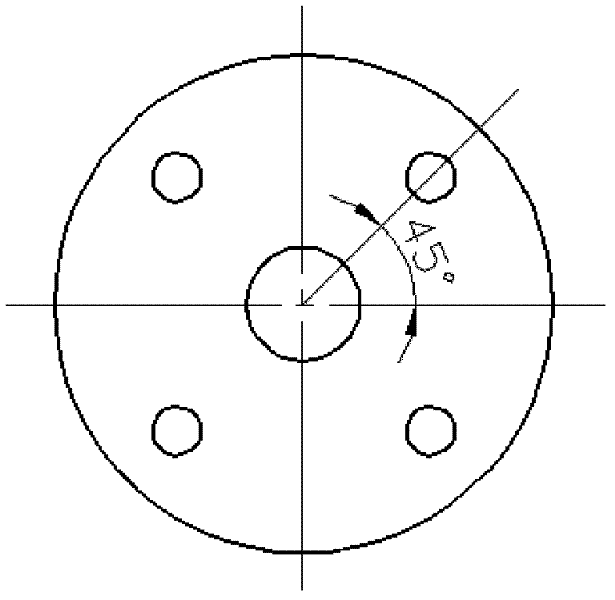

[0017] The basic principle of the experimental device for accurately measuring the characteristic parameters of the tool holder-spindle joint in this embodiment is to remove the servo, cooling and broaching devices on the machine tool, and adjust the broaching force by adding prestressed bolts according to the actual situation , and no additional factors are added to the overall test, so that the accurate identification of the characteristic parameters of the tool holder-spindle joint is achieved. This experimental device is figure 1 As shown, it includes a tool handle 1, a main shaft 2, a pull stud 3, an extension rod 4, a main shaft end cover 5, and a prestressed bolt 6. The main shaft end cover 5 is fixed on the end of the main shaft 2 by 4 bolts, the handle 1 is connected with the pull stud 3, and the pull stud 3 is fixed on the central hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com