Silicon wafer object table temperature control system of lithography machine and control method thereof

A technology of temperature control system and control system, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of equipment utilization rate reduction, process registration accuracy decrease, production capacity decrease, etc., to achieve the best process set The effect of quasi-precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in combination with principle diagrams and specific operation examples.

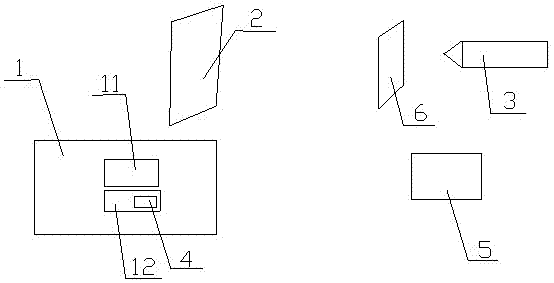

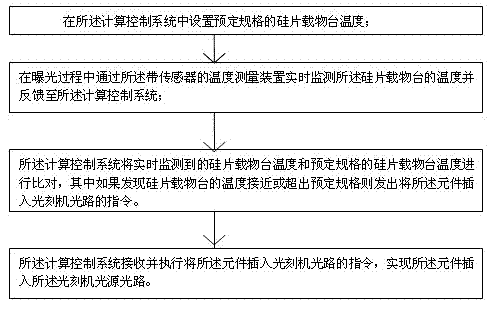

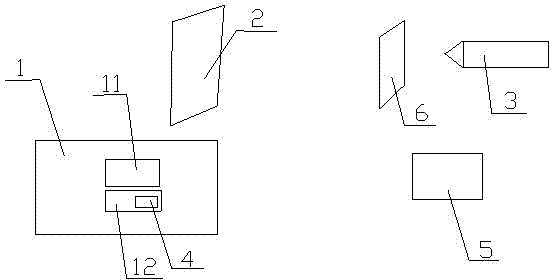

[0018] Such as figure 1 As shown, a silicon wafer stage temperature control system for a photolithography machine of the present invention includes a silicon wafer stage 1, a mask plate 2, and a light source 3 for a photolithography machine, wherein it also includes a temperature measuring device 4 with a temperature sensor, The element 6 and the calculation control system 5, the silicon wafer stage 1 is provided with a silicon wafer placement area 11 and a temperature measurement area 12, the silicon wafer placement area 11 is located at the front end of the temperature measurement area 12, and the temperature measurement area 12 A temperature measuring device 4 with a sensor is provided, the element 6 is located between the light source 3 of the lithography machine and the mask plate 2, the temperature measuring device 4 with a sensor, the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com