Integrated numerical control system and integrated numerical control machine

A technology of numerical control system and shell, applied in the direction of digital control, electrical program control, etc., can solve the problems of large synchronization effect and poor signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

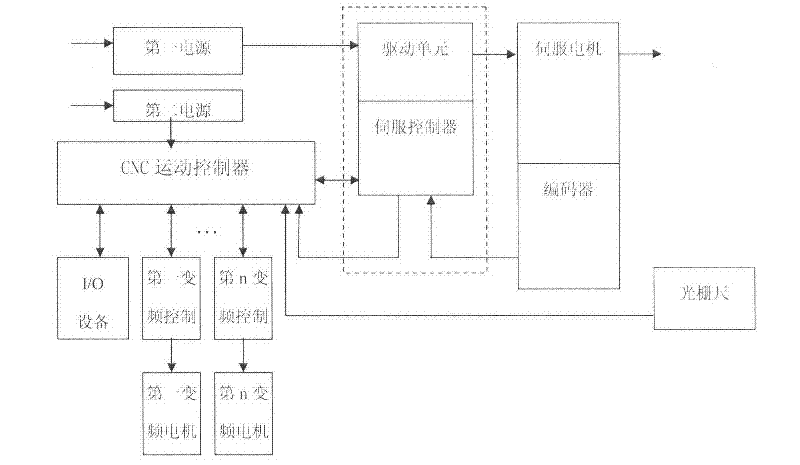

Problems solved by technology

Method used

Image

Examples

Embodiment 1

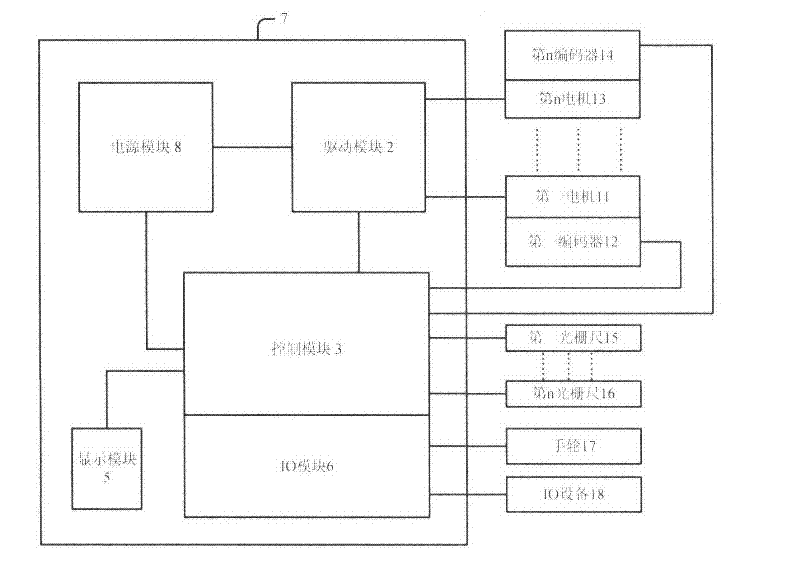

[0019] Embodiment 1. The present invention provides an integrated numerical control system, such as figure 2 As shown, it includes a housing 7 that shields the electromagnetic radiation source, and the housing 7 is provided with a power supply module 8, a control module 3, a drive module 2, a display module 5 and an I / O module 6;

[0020] The power supply module 8 provides power for the control module 3 and the drive module 2;

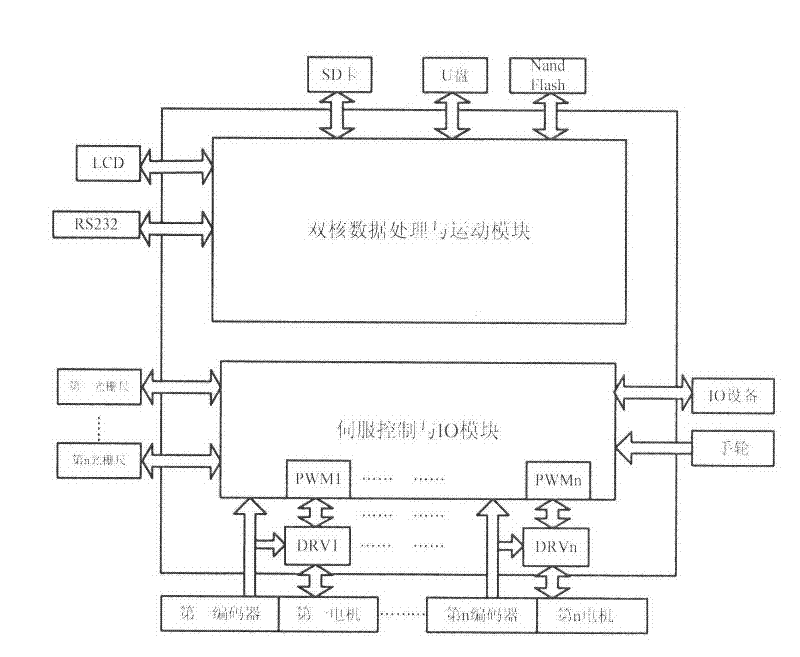

[0021] The control module 3 is connected with the drive module 2, the I / O module 6, and the display module 5, and is used to receive control information sent by an external I / O device through the I / O module 6; and according to the control information Send a control signal to control the movement of the motor to the drive module 2; the control module 3 is also used to collect current motor position information and current workbench position information, and perform corresponding processing on the current motor position information and current workbench...

Embodiment 2

[0038] Embodiment 2, the integrated numerical control machine tool of the present invention includes the above-mentioned integrated numerical control system, integrated numerical control machine tool, at least one spindle motor, at least one servo motor, and an encoder connected to the servo motor, and the control module sends to the drive module The control signal controls the spindle motor and the servo motor, collects motor information through an encoder, receives or sends control commands from the I / O module, processes data and sends display information to the display module.

[0039] The integrated CNC machine tool also includes a grating ruler connected to the control module, an I / O device and a hand wheel, and the control module collects the current motor position information and the current workbench position information through the encoder and the grating ruler, and receives the information from the I / O device. or send control signals.

[0040] It is worth mentioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com